29

31

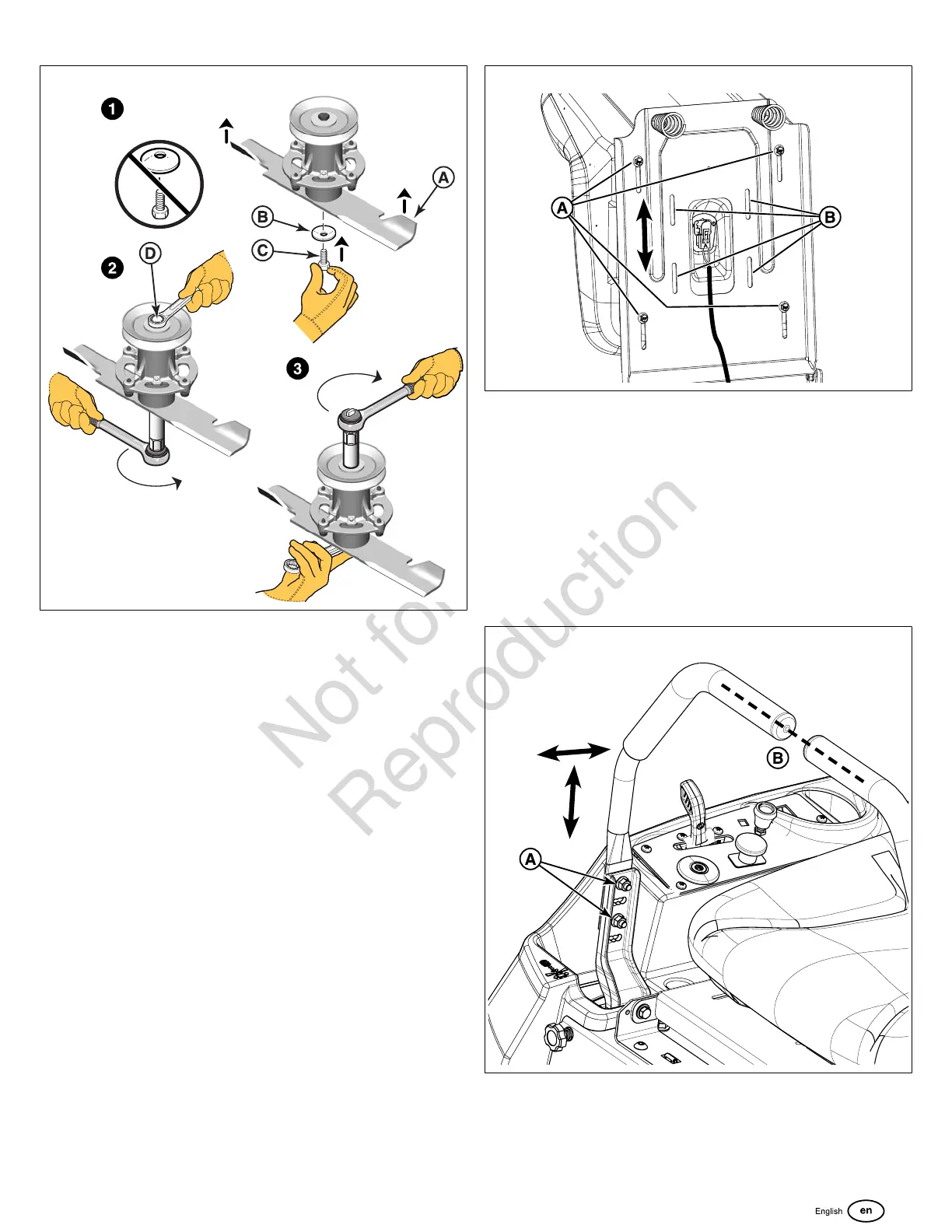

2. Tighten the blade mounting bolt to 50 - 60 ft. lbs. (68 - 81

Nm) of torque while holding onto the pulley bolt (D) with a

wrench.

3. Tighten the pulley bolt to 50 - 60 ft. lbs. (68 - 81 Nm) of

torque while holding onto the blade mounting bolt with a

wrench.

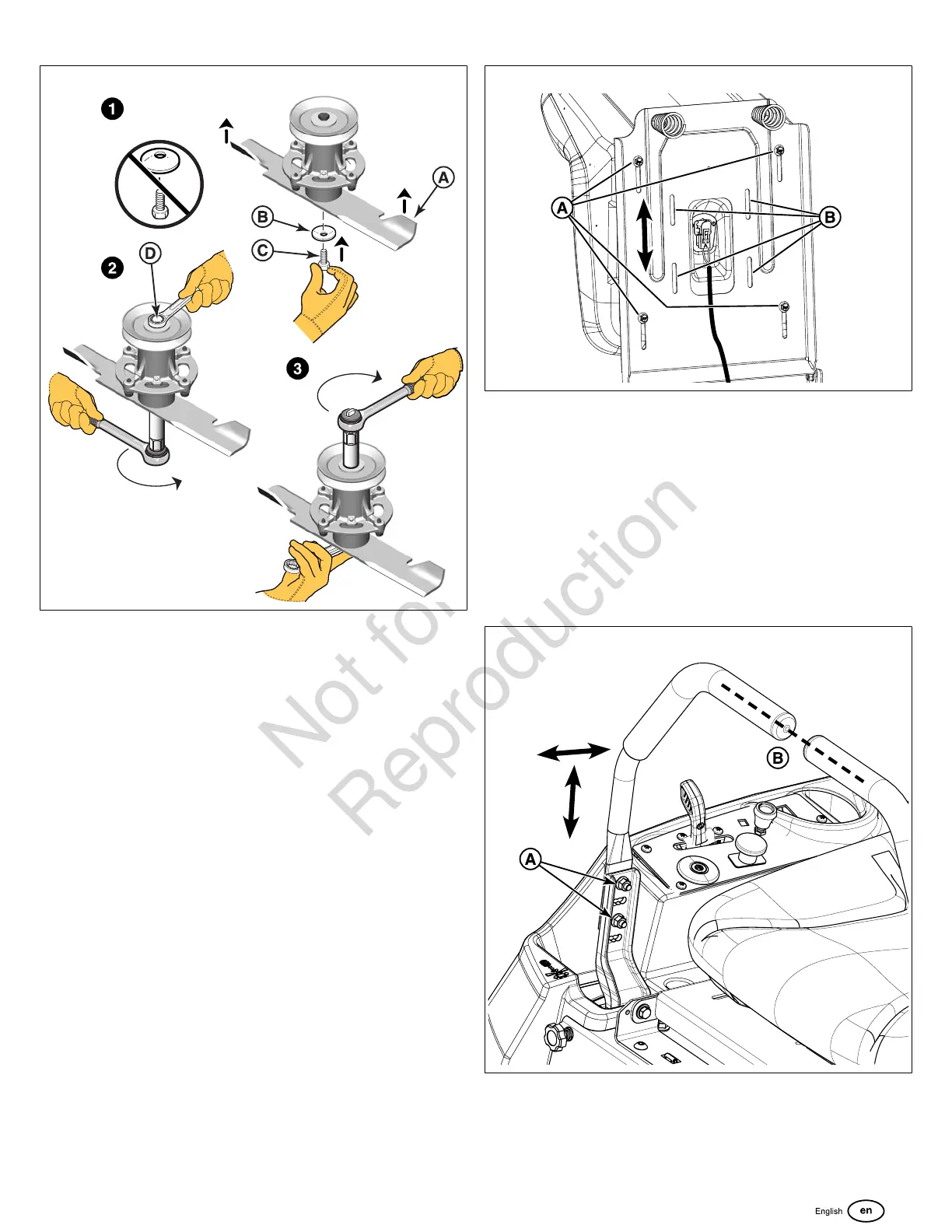

Seat And Ground Speed Control Lever

Adjustments

The seat and ground speed control levers should be adjusted

so that the ground speed control levers can be moved

through their full range of motion without contacting the

operator’s legs.

Seat Adjustment

1. Raise the seat.

2. Loosen the adjustment hardware (A or B, Figure32,

depending on seat type) under the seat base.

3. Slide the seat forward or backward to the desired

position.

4. Tighten the hardware to 80 lb-in (9 Nm).

32

Ground Speed Control Lever Adjustment

1. Loosen the ground speed control lever mounting

hardware (A, Figure33)to adjust the levers forward and

backward.

2. Remove the hardware to raise or lower the levers.

3. Always be sure to adjust both levers so that they are

aligned (B, Figure33).

4. After adjustment is complete, tighten the hardware to 13

lb-ft (18 Nm).

33

Speed Balancing (Tracking) Adjustment

If the unit drifts to the right or left when the ground speed

control levers are in the maximum forward position, the top

speed of each of these control levers can be balanced. Only

adjust the speed of the wheel that is traveling faster.

Loading...

Loading...