WARNING

Personal injury or equipment damage,

due to bursting of pressure-containing

parts may result if this regulator is

overpressured or is installed where

service conditions could exceed the limits

given in the characteristics section and

on the appropriate nameplate or where

conditions exceed any rating of the

adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices to prevent service conditions

from exceeding those limits. Also, be sure

that installation is in compliance with all

applicable code and regulations.

Physical damage to the regulator can

break the pilot off the main valve, causing

personal injury and property damage due

to bursting of pressure-containing parts.

To avoid such injury and damage, install

the regulator in a safe location.

and experience should install, operate and

maintain a regulator.

Before installation, make sure that there is

no damage to or debris in the regulator.

Make sure that all tubing and piping are

clean and unobstructed.

The regulator must be installed on

horizontal pipeline. For the version with

slam shut, the release relay must be

situated towards the bottom.

is recommended.

When assembling with adjacent elements

take care not to create pressure force on

the body. The assembling elements (bolts,

with the geometry and working conditions

of the equipment. If the case arises a

support must be used to avoid pressure

force on the body (a support can be

Connect the actuator to the impulse plug

keeping a minimum distance of 4 x D to a

straight run of the outlet pipe.

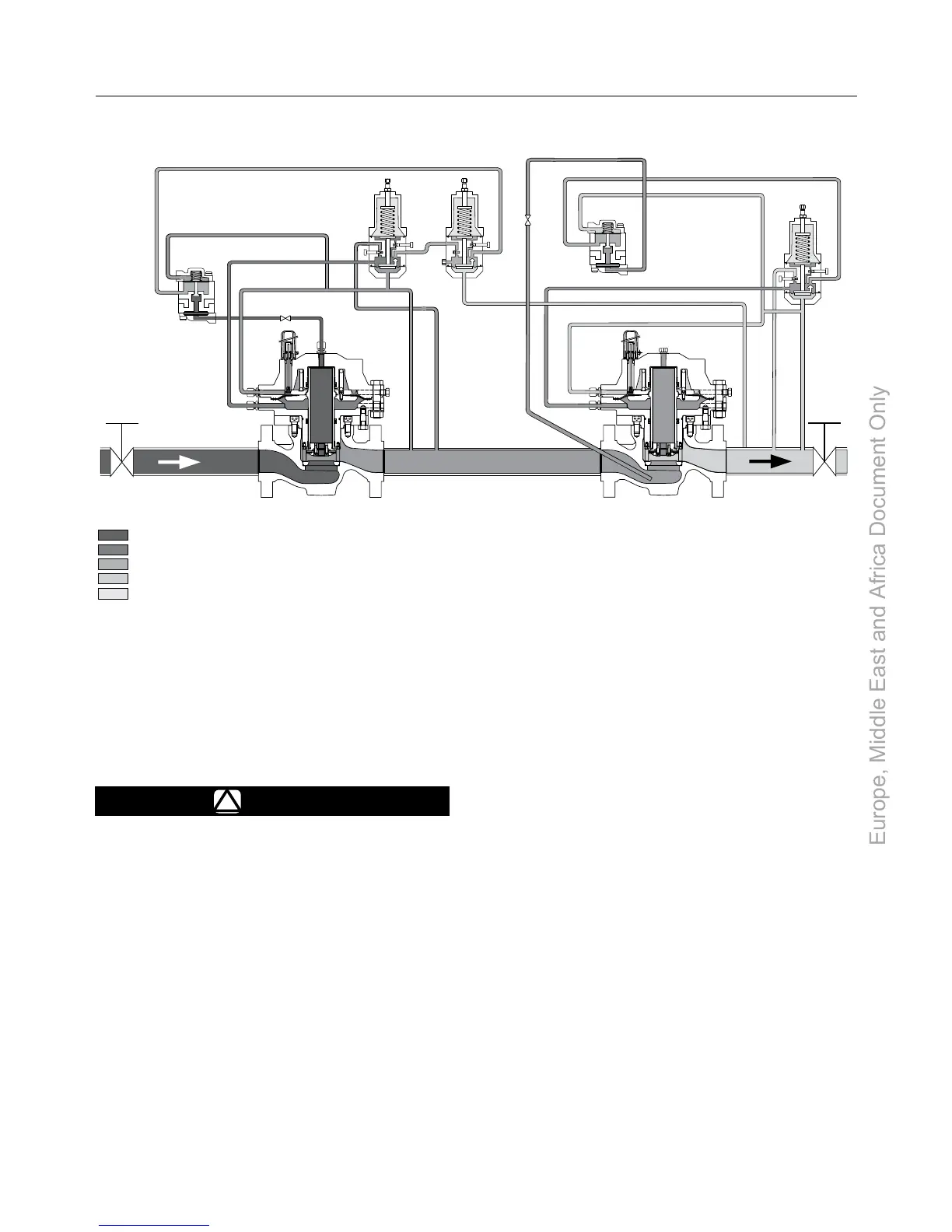

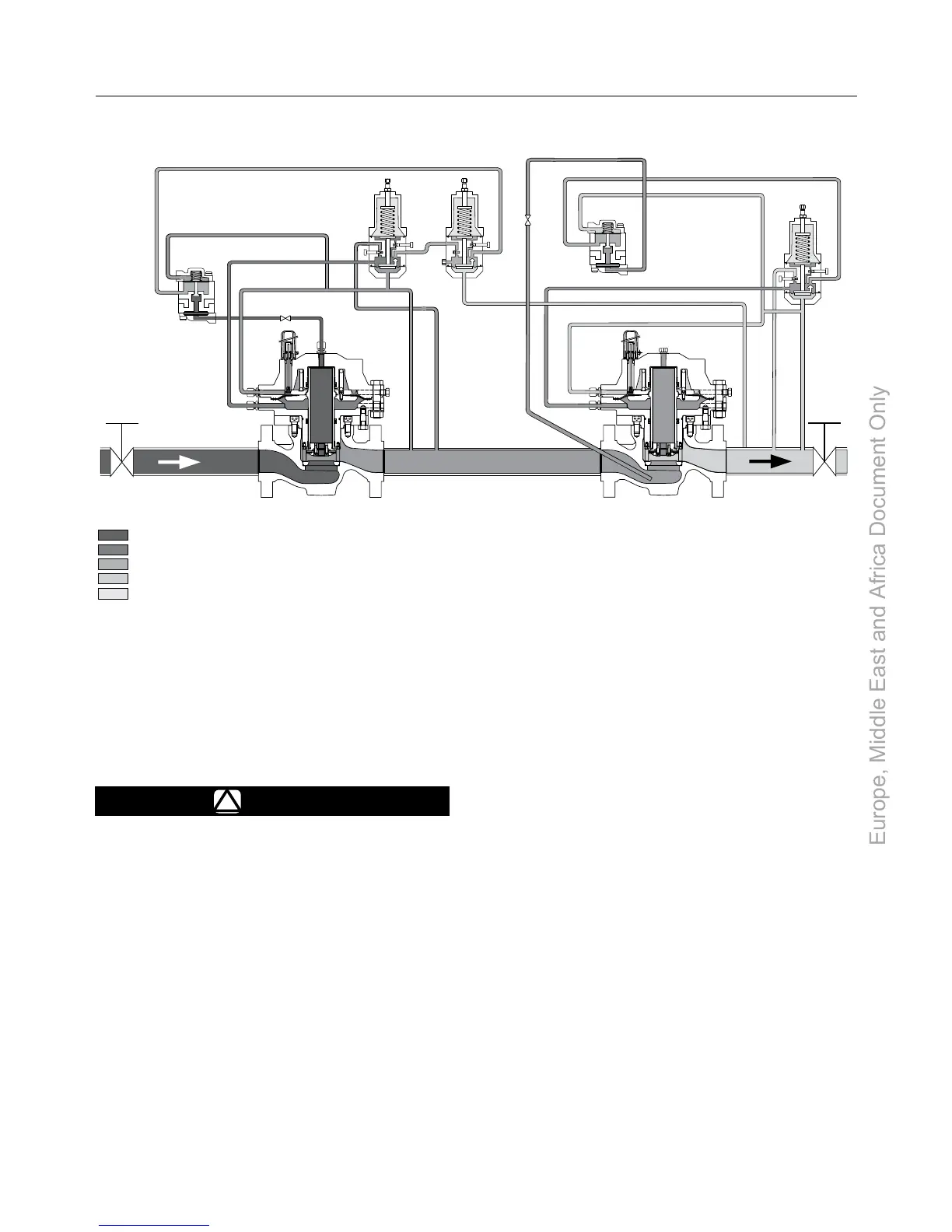

S - BLEED PORT TYPE SA/2

B - SUPPLY PORT V - SENSING

L - MOTORIZATION PORT R - PILOT

A - SENSING PORT M - INLET

INLET PRESSURE (Pu)

OUTLET PRESSURE (Pd)

MOTORIZATION PRESSURE (Pm)

PILOT FEEDING PRESSURE (Pup)

ATMOSPHERIC PRESSURE (Pb)

Loading...

Loading...