FIG_

39-Cleaning

Ring

Grooves

Check

the piston to cylinder

bore

cl

ear

ance with a tension scale

and

ribbon (covered

under

"

Fitt

ing

Pi

s~

tons") and the ring side

clearance

(covered

under

"

Fittin

g

Pi

st

on

Rings").

R

ep

lace

piston

pins showing signs

of

fracture

or

etching

and

lo

r wear.

Check the piston pin

fit

in

the

piston

and rod.

Replace all rings

that

arc

s

cored,

chipped,

or

cracked.

Check

the

end

gap

and

side clearance.

It

is

good

pr

actice to always install new rings

when overhauling

the

engine.

Rin

gs

should

not

be

transferred

from

one

piston to another regardless

of

mile-

age.

REPAIRS

Fitting Pistons. Pistons

are

a vail-

a

bl

e for serv

ic

e in standard sizes

and

0.020, 0.030, 0.040, and 0.060-inch

oversize.

If the

clearance

is

great

er

than

th

e maxim

um

limit, recheck calcula-

tions to be s

ure

that

the

pr

o

per

size

piston has been selected before try-

ing a new piston.

If

the

clearance

is less

than

the

mini

mum

limit, rech

eck

calculations

before trying

another

piston.

If

none

can

be fitted, refinish the cylinder for

the next

si

ze piston.

When

a

piston

has

been

fitted,

mark

it

for

assembly in the

cylinder

to which it was fitted.

If

the

taper

and

out-of-round

con-

ditions

of

the cylinder

bore

are

within

limit

s,

new piston rings w

ill

give sat-

isfac

tory

service provided the piston

clearance in the cylinder

bore

is

within limits.

If

the

new rings

are

to

be

in

stalled in a used cylinder

that

has not

been

refinished,

remove

the

cylinder wall

"glaze."

To

fit a piston:

1. Calculate the s

iz

e piston to be

used by taking a

bore

check (Fig. 46).

2. Select

the

prop

er size

piston

to

provide the desired

clear

ance.

3.

Make

sure

the piston and cyl-

inder block

are

at

room

te

mperature

PART 1 -1 -

GENERAL

ENGINE

SERVICE

1-23

~I

o

3\

~

12

o

~

I

I

.,

~ 10

5

~

9

"

:> 6

"

'"

7

z

:1:

6

4

1;4

cc

POUNDS

ii

5

(E

XAMPLE)

4

3

2

o

\

\

1\

1\

\

\

-.002

\

\

\

1\ \

1\

\

\

\

- .001

\

1\

1\ \

1\ \

\

\

1\

\

\

\

\

,/

1\

l)(

1\ \

'\ 1/

V \

li

\

\

\

\

\:

\

\i \

-

0+

.001

\

V ·00

4

5

LX-

.004

V .0035

1'(,

r:;;

V·003

_

.002

5

YCJ\V

It

.002

V

~/

1\,00

15

"V

rY4..\

\

)<

\

1\ 1\ \

\ \ \

\

\

1\

\ \

'\

\

\

1\

1\ \ \

\

\

\ \

\

RIBBON

RIBBON

RIBBON

RIBBON

RIBBON

R

IB

BON

RIBBON

\

\

1\ \

\

4

POUNDS

(EXAMPLE)

.002

.003 .004 .005

CLEA

RA

NCE

IN

INCHES

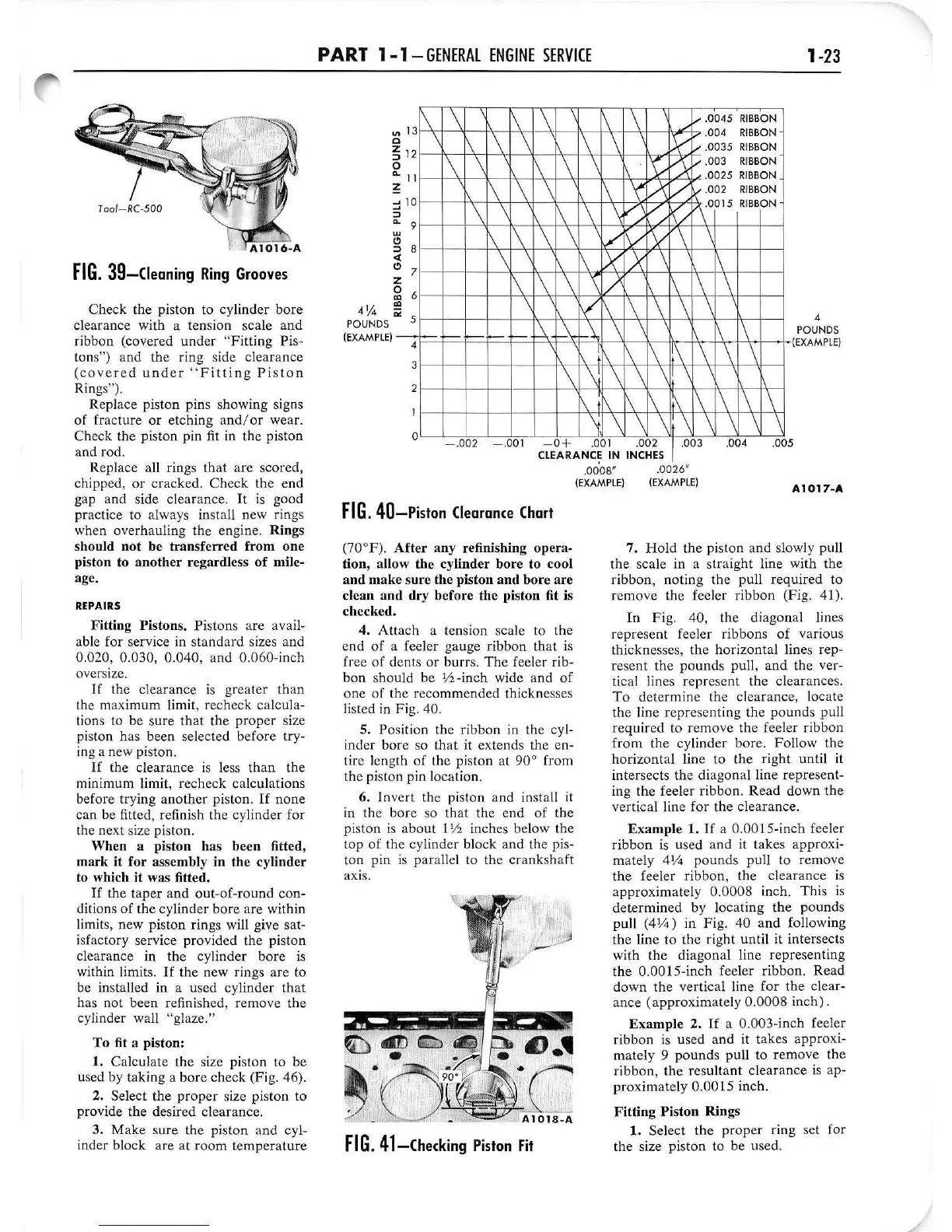

FIG.

40-Piston

Clearance

Chart

(70°F).

After

any

refinishing

opera-

tion

, allow

the

cylinder

bore

to cool

and

make

s

ur

e

the

piston

and

bore

are

clean

and

dry

before

the

piston fit

is

checked.

4.

Attach

a tension scale to the

end

of

a feeler

ga

uge

ribbon

that is

free

of

dents

or

burrs.

The

feeler rib·

bon

should

be 1/2 -in

ch

wide and

of

one

of the reco

mm

ended

thi

ckne

sses

listed

in

Fig.

40

.

5.

Po

si

ti

on the ribbon in the cyl-

ind

er

bore

so

that

it extends the e

n-

tire length

of

the piston at

90

°

from

the piston pin location.

6.

In

ve

rt the piston and

in

sta

ll

it

in the bore so

that

the e

nd

of

the

piston is about

l Y2 inches below the

top

of

the

cy

linder block

and

the pis·

ton

pin is parallel

to

the

crankshaft

axis.

FIG,

41-Checking

Piston

Fit

.

0008"

(EXAMPLE)

.

0026"

(EXAMPLE)

Al017-A

7. Hold the piston a

nd

slowly pull

the scale in a straight line with the

ribbon, noting

the

pull

required

to

remove

the feel

er

ribbon

(Fig. 41).

In

Fig. 40, the diagonal lines

represent

fe

eler ribbons

of

various

thicknesse

s,

the

horizontal

lines rep-

resent

the

pounds

pull,

and

the

ver-

ti

ca

l

li

nes represent the

clearances

.

To

determine

the clea

rance

, l

ocate

the line

representing

the

pounds

pu

ll

re

quir

ed to

remove

the feeler

ribbon

from

the

cylin

der

bo

re.

Follow

the

horizontal

line to the right until it

intersects the

diagona

l line represent-

ing the feeler ribbon. R

ea

d

down

the

vertical line for the cl

earance.

Example 1.

If

a

O.OO

IS-inch

feeler

ribbon

is used

and

it

takes

approxi-

mately

414

pounds

pull to

remove

the

feeler ribbon, the

clearance

is

approximately

0.

0008

inch.

Thi

s is

determined

by

locating

the

pounds

pull

(41

;';)

in F ig. 40

and

following

the line to the

ri

g

ht

until

it intersects

with

the

diagonal

line

repre

senting

the

0.00

l5-inch

feeler ribbon.

Read

down

the

vertical line

for

the

clear-

anc

e

(approx

im

ate

ly

0.0008

inch) .

Example

2.

If

a 0.003-inch feeler

ribbon

is used a

nd

it

takes

approxi

-

mately 9

pounds

pull to

remove

the

ribbon, the res

ultant

clea

ran

ce is ap-

proximately

0.00

15 inch.

Fitting

Piston

Rings

1.

Select the

proper

ring set fo r

the size piston to be used.

Loading...

Loading...