PRE-OPERATION----

1

Before operating the loader,

for

optimum stability, ad-

ditional weight should

be

added

to

the rear

of

the trac-

tor

with

rear wheel weights or liquid ballast. Refer

to

your tractor operator's manual

for

weighting informa-

tion.

The effective counterbalance weight

of

mounted rear

equipment

is

determined by multiplying the actual

weight

of

equipment by 1.50.

EXAMPLE: Equipment weighing 800 pounds, attach-

ed

to the rear

of

the tractor, multiplied

by

1.50,

equals

1200

pounds

of

effective counterbalance weight.

-----OPERATION

The loader should be operated

with

the tractor engine

running at 1700-2200 rpm. Excessive speeds are

dangerous, and may cause bucket spillage and un-

necessary strain on the tractor and loader.

When operating in temperatures below

30°

F., run the

tractor engine below 1200 rpm until the oil

temperature exceeds

30°

F.

The following text and illustrations offer suggested

loader and tractor operating techniques.

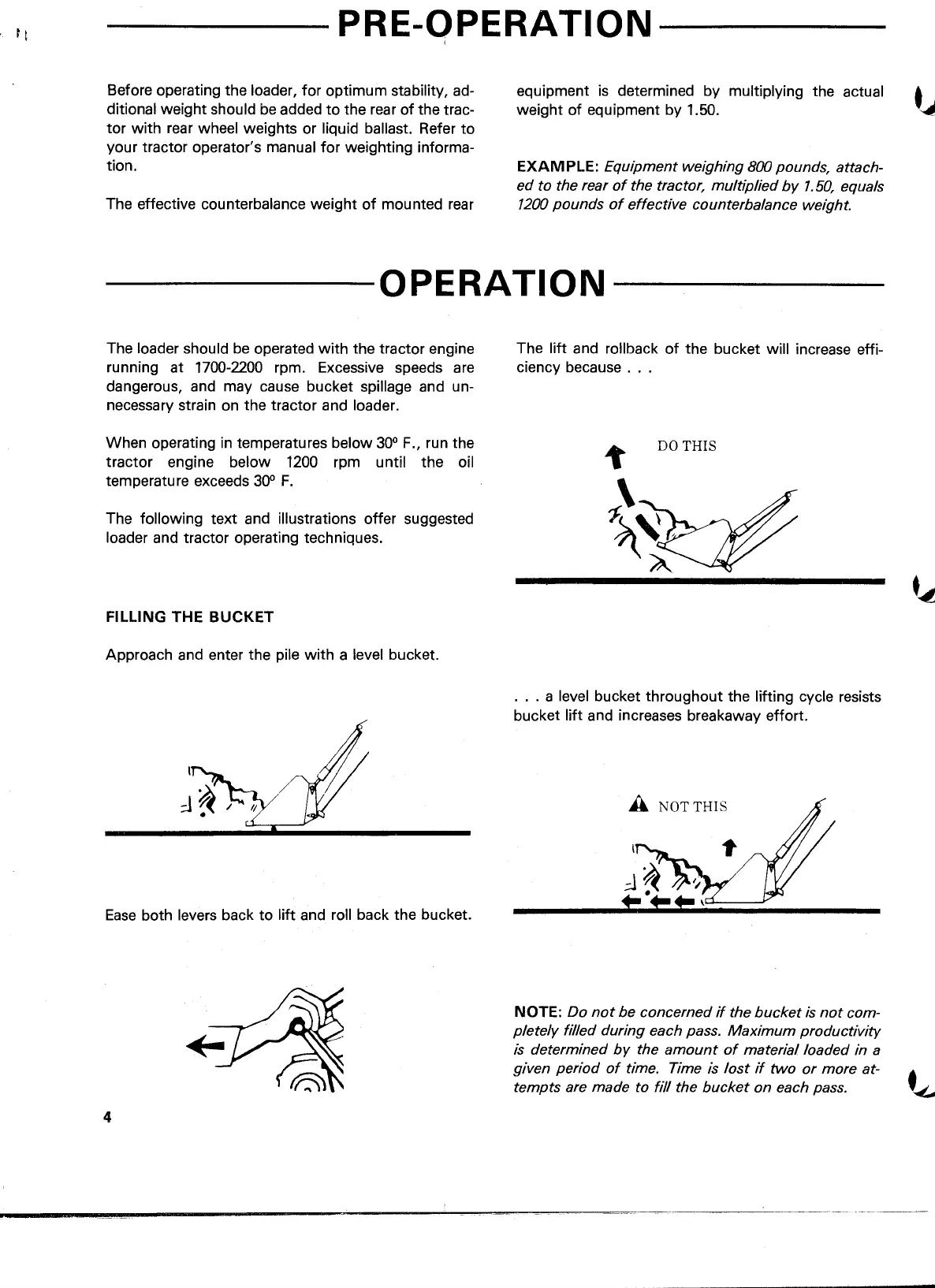

FILLING THE BUCKET

Approach and enter the pile

with

a level bucket.

Ease

both levers back

to

lift and roll back the bucket.

4

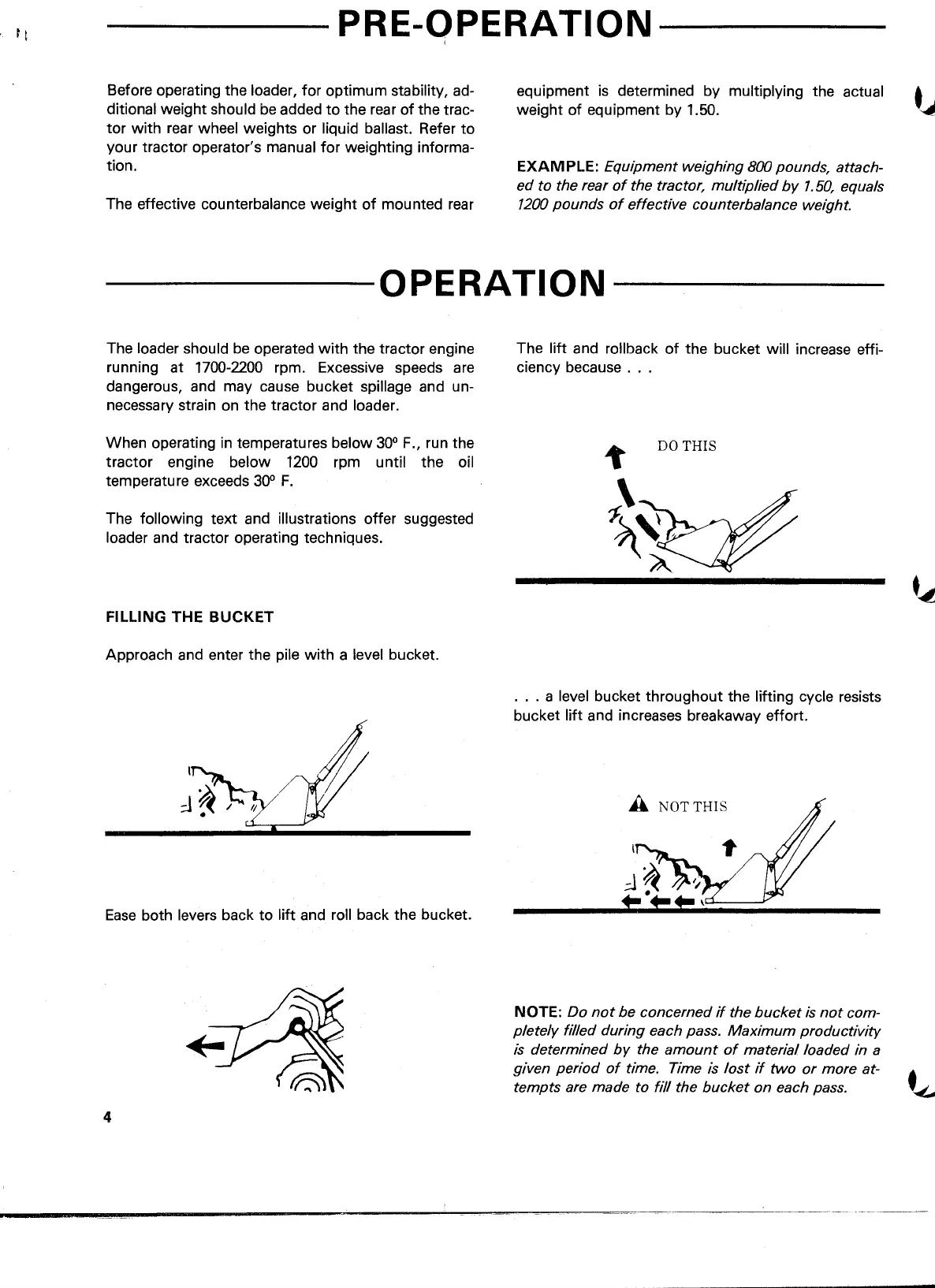

The lift and rollback

of

the bucket will increase effi-

ciency because

...

DO

THIS

.

..

a level bucket throughout the lifting cycle resists

bucket lift and increases breakaway effort.

A

NOTTHIS

NOTE:

Do

not

be concerned

if

the

bucket

is

not

com-

pletely filled during each pass.

Maximum

productivity

is determined

by

the

amount

of

material loaded in a

given

period

of

time. Time is

lost

if

two

or

more at- f

tempts are made to

fill

the

bucket

on each pass.

~

Loading...

Loading...