11-03-1

Wheels and Tires—Two-Piece Rims

11-03-1

PART 11-03 Wheels and Tires-Two-Piece Rims

Applies to F-250-F-350 Vehicles

COMPONENT INDEX

TIRE REMOVAL

AND MOUNTING-

Two-Piece Rims

Page

03-1

COMPONENT INDEX

TIRE REMOVAL

AND

MOUNTING

-

Two-Piece Semi-Drop

Center Rims

Page

03-2

DESCRIPTION

Two-piece rims are used on disc and

cast wheels with tube-type tires only.

Refer to Part 11-01 for safety

procedures and illustrations.

REMOVAL AND INSTALLATION

The tire must be completely deflated

before removal, and the bead must not be

damaged by a tire iron.

After installation, a tube tire should

be inflated to recommended pressure,

deflated, and then inflated again to insure

that the tube is not folded inside the tire.

Be sure the tube flap is properly

positioned before inflating the tire.

It is recommended that tire-changing

equipment be used in changing all truck

tires.

See Safety Precautions in Part

11-01.

TIRE REMOVAL AND

MOUNTING—TWO-PIECE RIM

Removing Tire from Wheel

If no tire-changing machine is

available, remove tire as detailed in

following Steps.

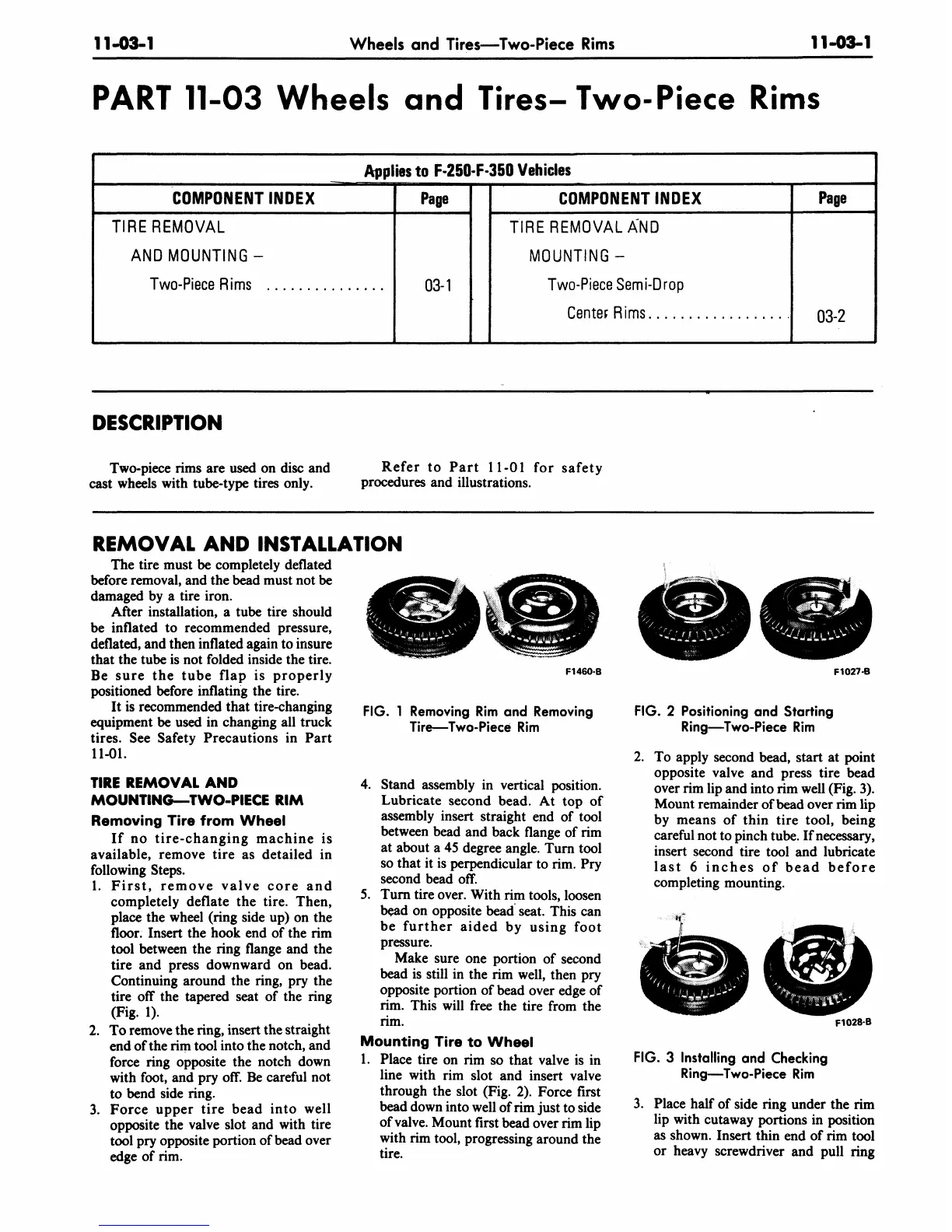

1.

First, remove valve core and

completely deflate the tire. Then,

place the wheel (ring side up) on the

floor. Insert the hook end of the rim

tool between the ring flange and the

tire and press downward on bead.

Continuing around the ring, pry the

tire off the tapered seat of the ring

(Fig. 1).

2.

To remove the

ring,

insert the straight

end of the

rim

tool into the notch, and

force ring opposite the notch down

with foot, and pry off. Be careful not

to bend side ring.

3.

Force upper tire bead into well

opposite the valve slot and with tire

tool pry opposite portion of bead over

edge of rim.

F1460-B

FIG.

1 Removing Rim and Removing

Tire—Two-Piece Rim

4.

Stand assembly in vertical position.

Lubricate second bead. At top of

assembly insert straight end of tool

between bead and back flange of rim

at about a 45 degree angle. Turn tool

so that it is perpendicular to rim. Pry

second bead off.

5.

Turn tire over. With rim tools, loosen

bead on opposite bead seat. This can

be further aided by using foot

pressure.

Make sure one portion of second

bead is still in the rim well, then pry

opposite portion of bead over edge of

rim. This will free the tire from the

rim.

Mounting Tire to Wheel

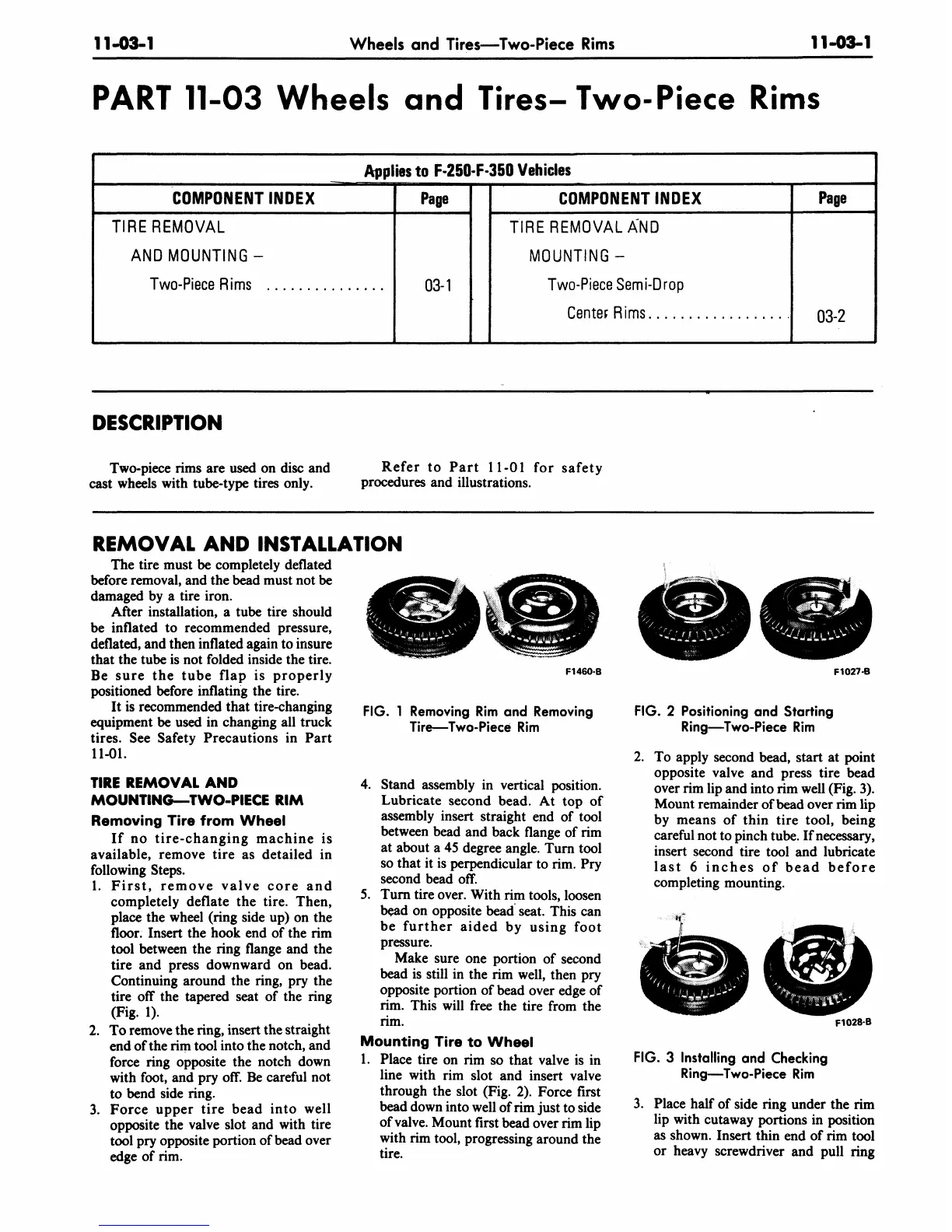

1.

Place tire on rim so that valve is in

line with rim slot and insert valve

through the slot (Fig. 2). Force first

bead down into

well

of

rim

just to side

of valve. Mount

first

bead over

rim

lip

with rim tool, progressing around the

tire.

F1027-B

FIG.

2 Positioning and Starting

Ring—Two-Piece Rim

2.

To apply second bead, start at point

opposite valve and press tire bead

over

rim

lip

and into

rim

well

(Fig.

3).

Mount remainder of bead over

rim

lip

by means of thin tire tool, being

careful not to pinch

tube.

If necessary,

insert second tire tool and lubricate

last 6 inches of bead before

completing mounting.

F1028-B

FIG.

3 Installing and Checking

Ring—Two-Piece Rim

3.

Place half of side ring under the rim

lip with cutaway portions in position

as shown. Insert thin end of rim tool

or heavy screwdriver and pull ring

Loading...

Loading...