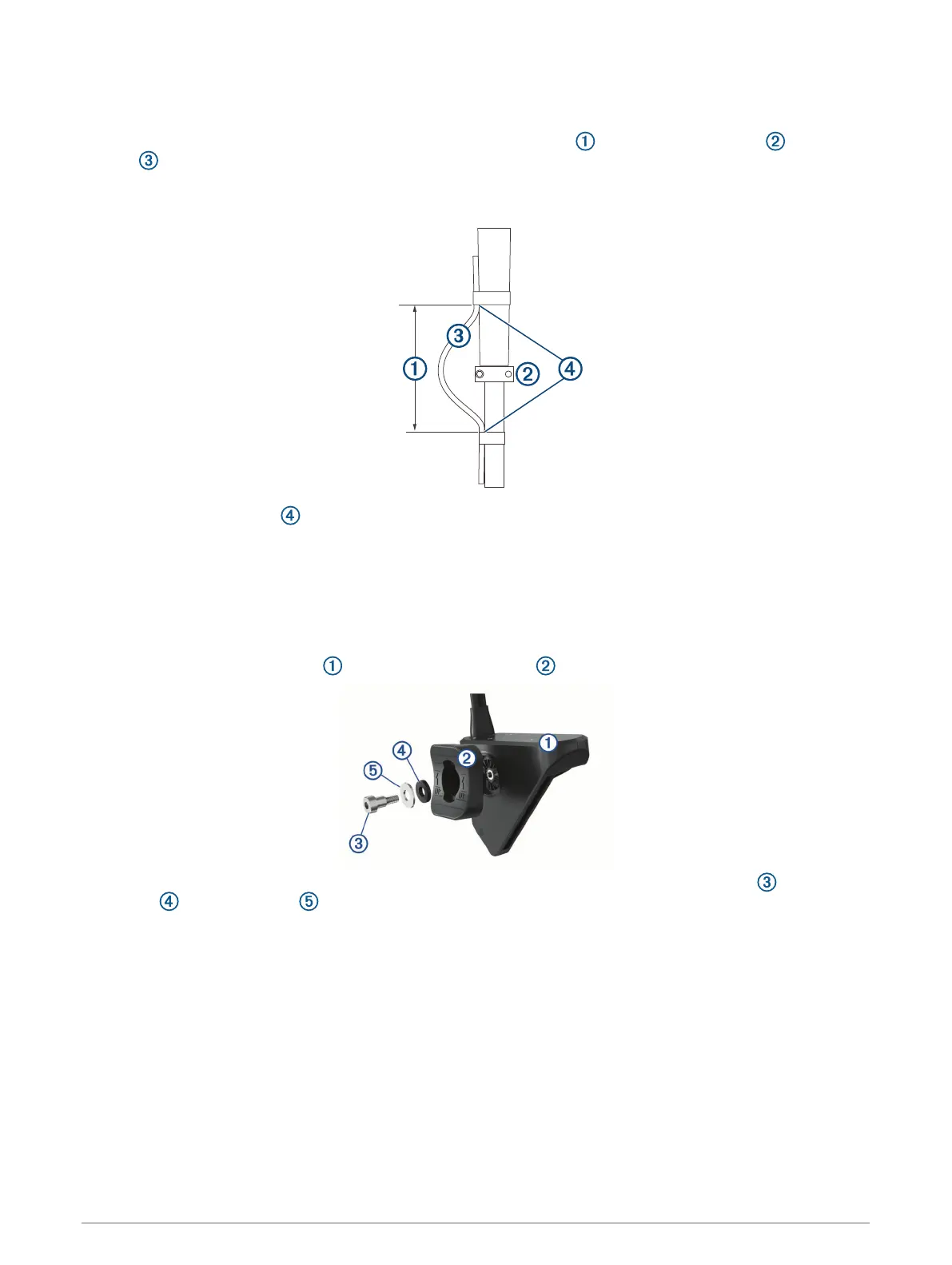

Routing the Transducer Cable

You should test-fit the transducer and cable before installation.

1 Allow a loose gap of at least 10 cm ( 4 in.) above and 10 cm (4 in.) below the rotating joint to create a

loop in the cable. The loop must be large enough to allow full rotation of the transducer in both

directions. Allow a minimum of 25 cm (10 in.) of cable to cover the 20 cm (8 in.) section between mounting

points.

2 Use black electrical tape to secure the transducer cable to the shaft.

3 Test the full rotation of the trolling motor to ensure the cable clears the rotating joint and is not pulled tight

due to tension during rotation.

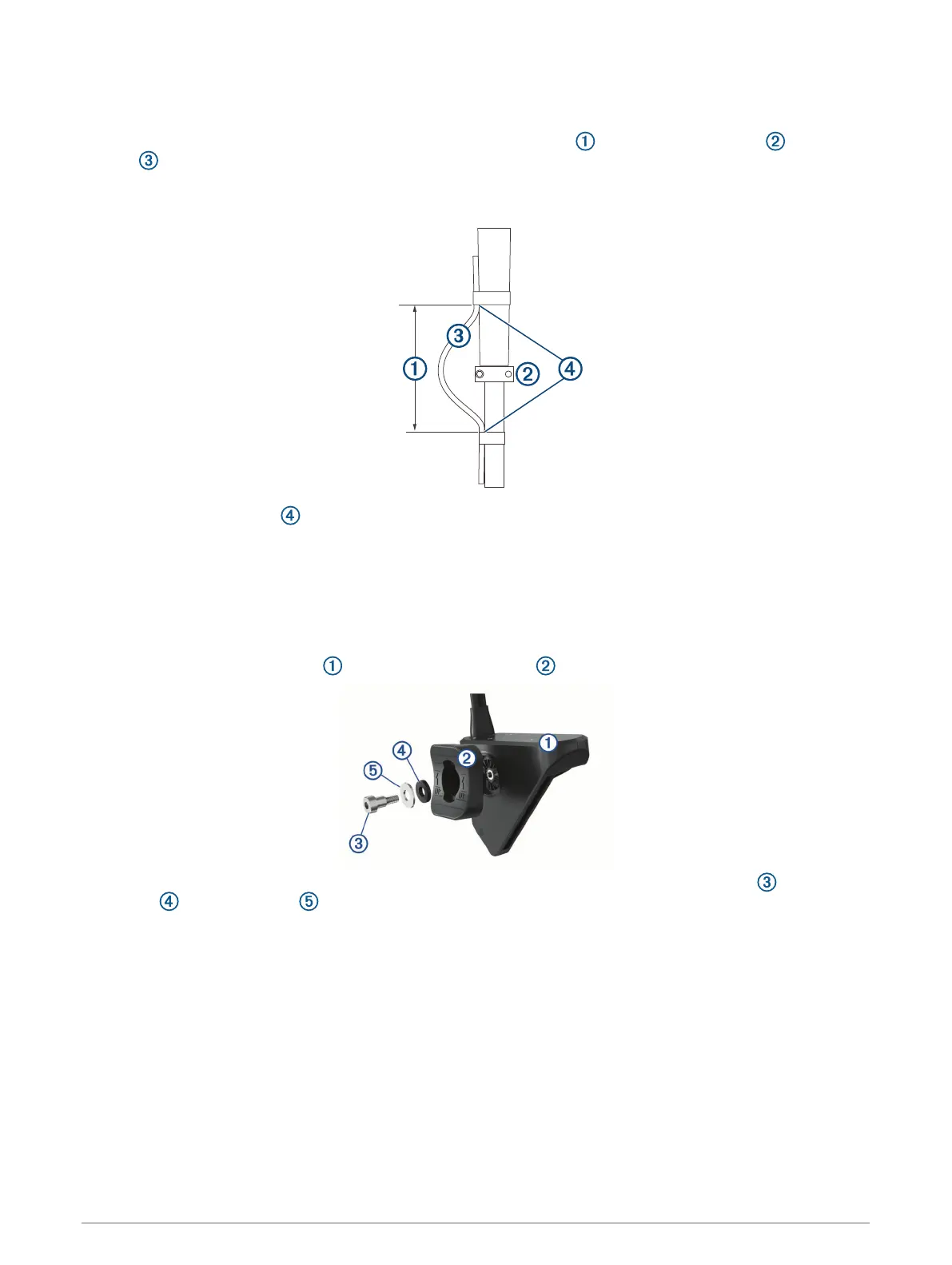

Installing the Transducer on a Trolling Motor

Assembling the Trolling Motor Barrel Mount Hardware

1 Align the top of the transducer with the top of the bracket .

2 Using the included hex wrench, attach the bracket to the transducer with the shoulder screw , rubber

washer , and flat washer .

NOTE: You must fully tighten the mount to the transducer. The recommended torque applied to the shoulder

screw is 2.5 lb-ft. (3.4 N-m).

3

Loading...

Loading...