Page 22

PART 2

AC GENERATORS

SECTION 2.1

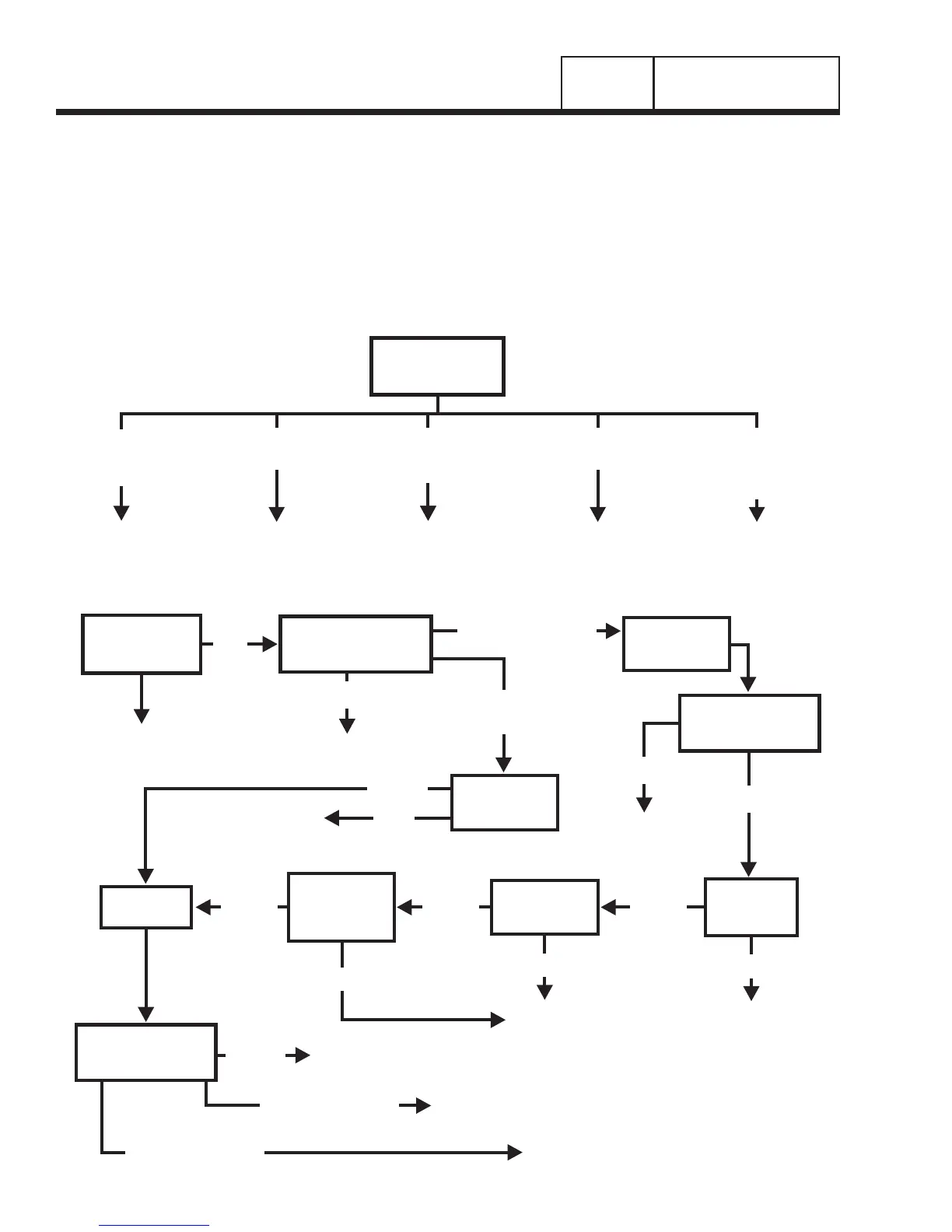

BRUSHLESS CAPACITOR TROUBLESHOOTING FLOWCHARTS

The GP series portable generators currently use

three different types of alternators. Two of the alterna-

tors are brushless capacitor type with different style of

capacitors (Configuration “A” and “B”). The third uti-

lizes a voltage regulator and a brushed excitation sys-

tem (Configuration “C”). To help with troubleshooting,

two sets of flow charts have been created for these

different styles of alternators.

Identify the configuration of the alternator being ser-

viced using Sections 1.3 and 1.4 of this manual and

proceed to the appropriate flowchart section.

Configuration “A” – Brushless Capacitor, use Section 2.1

Configuration “B” – Brushless Capacitor, use Section 2.1

Configuration “C” – Brushed Excitation, use Section 2.2

GO TO PROBLEM 2 GO TO PROBLEM 1GO TO PROBLEM 4 VERIFY ROTOR IS SPINNING,

GO TO PROBLEM 1

GO TO PROBLEM 3

VOLTAGE &

FREQUENCY BOTH

HIGH OR LOW

FREQUENCY GOOD

VOLTAGE HIGH

ZERO VOLTAGE

ZERO FREQUENCY

FREQUENCY GOOD,

LOW OR RESIDUAL

VOLTAGE

TEST 1 - CHECK

NO LOAD VOLTAGE

& FREQUENCY

NO LOAD VOLTAGE &

FREQUENCY GOOD -

VOLTAGE/FREQUENCY

FALLS OFF UNDER LOAD

If Problem Involves AC Output

REPLACE

ALTERNATOR

REPLACE

ROTOR

STOP TESTING

BAD

BAD

GOOD

GOOD

CONFIGURATION “B”

GOOD

CONFIGURATION “A”

BAD

CONFIGURATION “B”

BAD

CONFIGURATION “A”

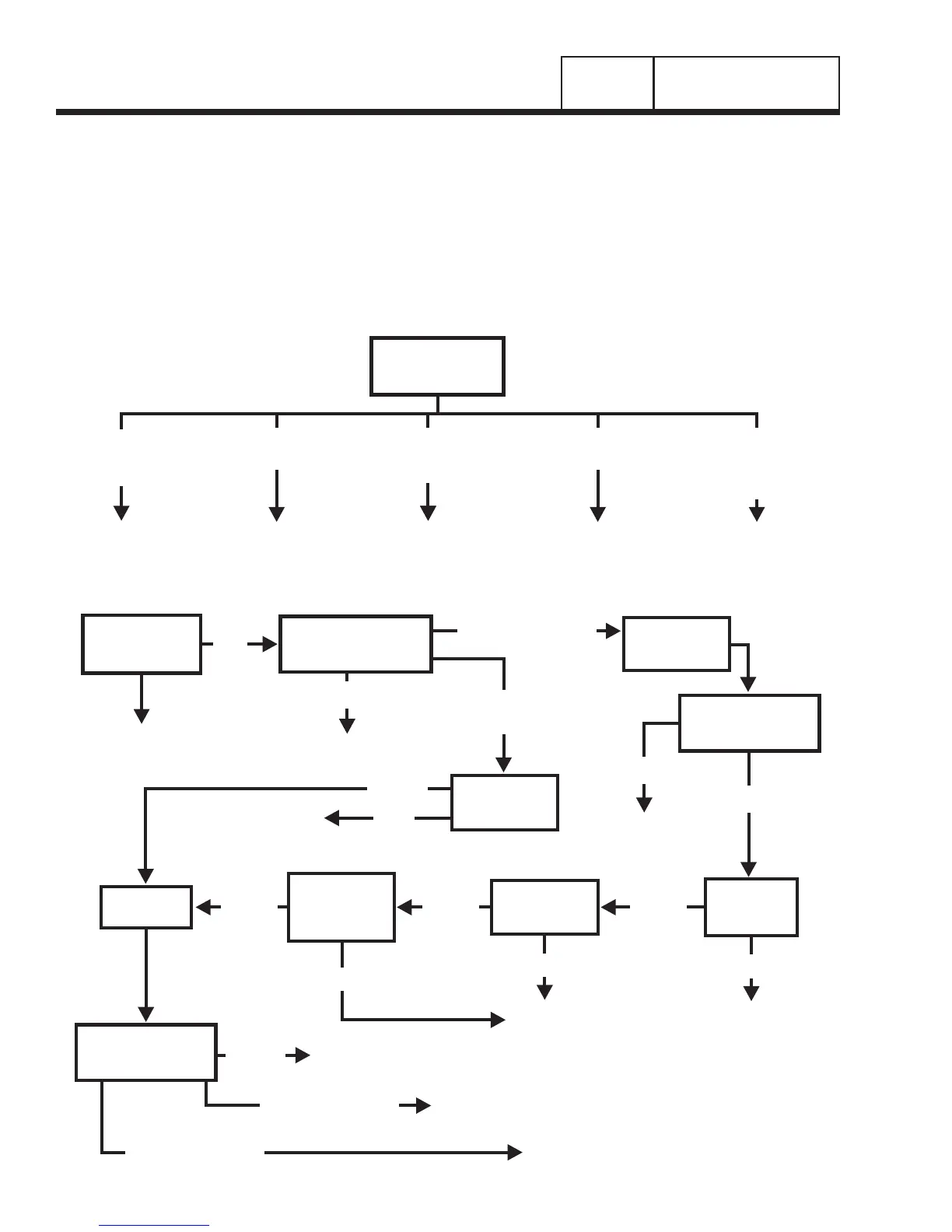

Problem 1 – Generator Produces Zero Voltage or Residual Voltage

TEST 2 – CHECK

MAIN CIRCUIT

BREAKER

RESET TO “ON”

OR REPLACE IF BAD

REPLACE COMPONENT

AS NEEDED

STOP

TESTING

TEST 3 – CHECK

CONTINUITY OF

RECEPTACLE PANEL

RE-CHECK VOLTAGE

AT RECEPTACLE

PANEL

RE-CHECK VOLTAGE

AT RECEPTACLE

PANEL

TEST 4 – FIELD

FLASH

ALTERNATOR

REPLACE

BAD

BAD

BAD

REPLACE

S TATO R

BAD

REPLACE

ALTERNATOR

REPLACE

CAPACITOR

ON

GOOD

GOODGOODGOOD

TEST 6 –

CHECK

CAPACITOR

TEST 7 – TEST

BRUSHLESS

DPE WINDING

TEST 8 – TEST

BRUSHLESS

STATOR

WINDINGS

TEST STATOR

FOR SHORTS

TO GROUND

GOOD

Loading...

Loading...