Page 42

TEST 20 – CHECK 1.5 AMP FUSE

Figure 1. A Typical 1.5 Amp Fuse

DISCUSSION:

The fuse protects the wiring and the battery charger

from a short circuit.

PROCEDURE:

Push in on fuse holder cap and turn counterclockwise.

Then, remove the cap with fuse. Inspect the fuse.

RESULTS:

If the fuse element has melted open, replace the fuse

with an identical size fuse. If fuse is good, refer back

to flow chart.

TEST 21 – CHECK BATTERY & CABLES

PROCEDURE:

Inspect the battery cables and battery posts or termi-

nals for corrosion or tightness. Measure the voltage at

the terminal of the Starter Contactor and verify 11-12

volts DC is available to the generator during cranking.

If voltage is below 11 volts DC, measure at the battery

terminals during cranking. If battery voltage is below

11 volts DC, recharge/replace battery. If battery or

cables are still suspected, connect an alternate bat-

tery and cables to the generator and retest.

RESULTS:

1. Clean battery posts and cables as necessary. Make sure

battery cables are tight.

2. Recharge the battery, if necessary.

3. Replace the battery, if necessary.

4. If battery is good, but engine will not crank, refer back to

Flow Charts.

TEST 22 – CHECK VOLTAGE AT STARTER

CONTACTOR (SC)

PROCEDURE:

1. Set voltmeter to measure DC voltage.

2. Disconnect Wire 16 from the Starter Contactor located

on the Starter motor.

3. Connect the positive meter test lead to Wire 16 previ-

ously removed. Connect the negative meter test lead to

frame Ground.

4. Place the START-RUN-STOP Switch to START. 12 VDC

should be measured.

5. Reconnect Wire 16 to the Starter Motor.

RESULTS:

Refer back to flow chart.

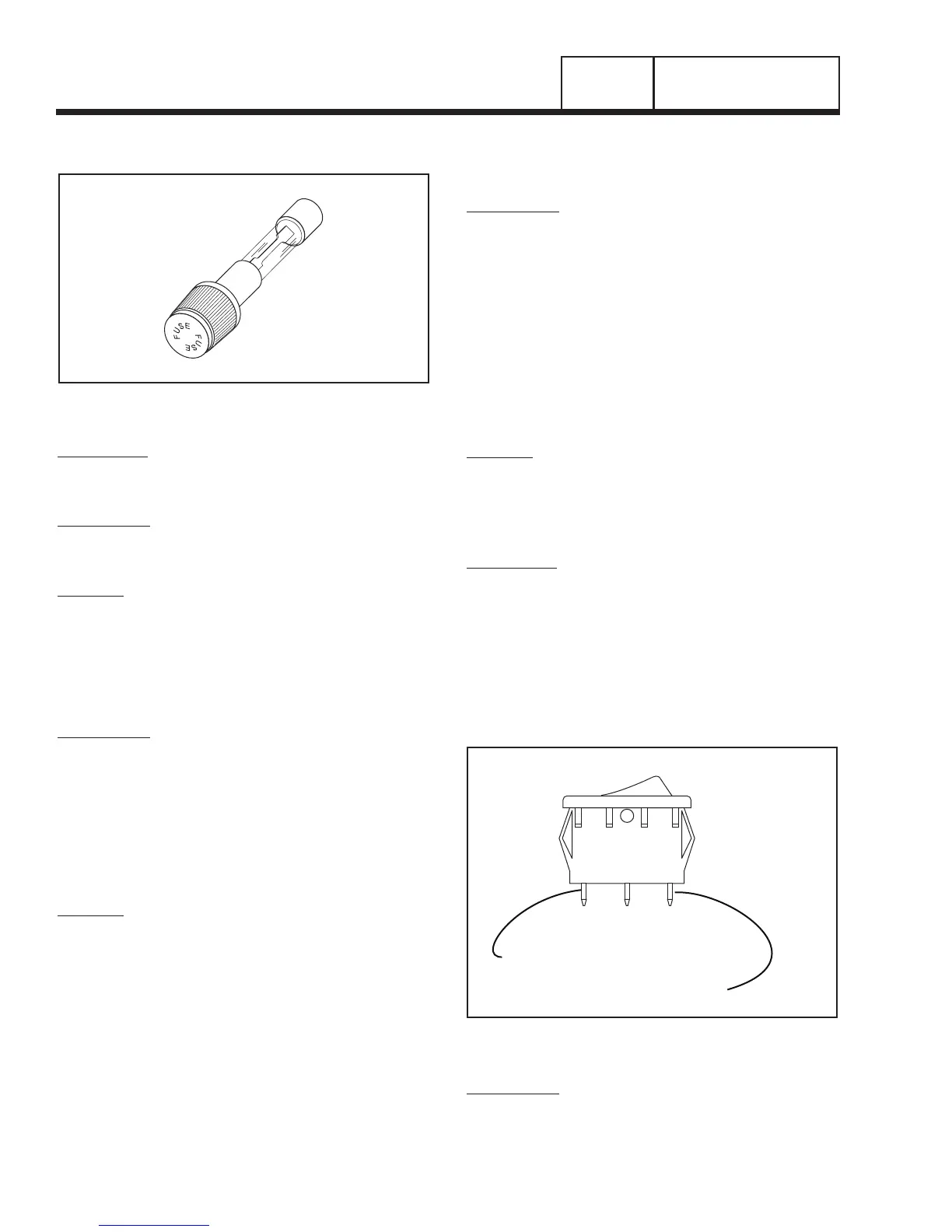

TEST 23 – CHECK START-RUN-STOP SWITCH

DISCUSSION:

The START-RUN-STOP switch utilizes ground potential

to start and shutdown the engine. When the switch is

actuated to the START position a ground is applied to

the starter contactor where positive 12VDC is already

available allowing the engine to crank. Once the ground

is removed by putting the switch in the RUN posi-

tion it disengages the starter allowing the engine to

operate normally. When the switch is actuated to the

STOP position a ground is applied to the magneto coils

grounding them out and inhibiting spark from occurring.

1A 1B1

WHT

STOP RUN START

0 GD 13A

TO MAGNETO

GROUND TO

STARTER CONTACTOR

Figure 2. START-RUN-STOP Switch

PROCEDURE:

1. Set a voltmeter to measure resistance.

2. Remove all wires from the START-RUN-STOP Switch

(SW1).

PART 3

DC CONTROL

SECTION 3.3

DIAGNOSTIC TESTS

Loading...

Loading...