28

221469B

11 Commissioning

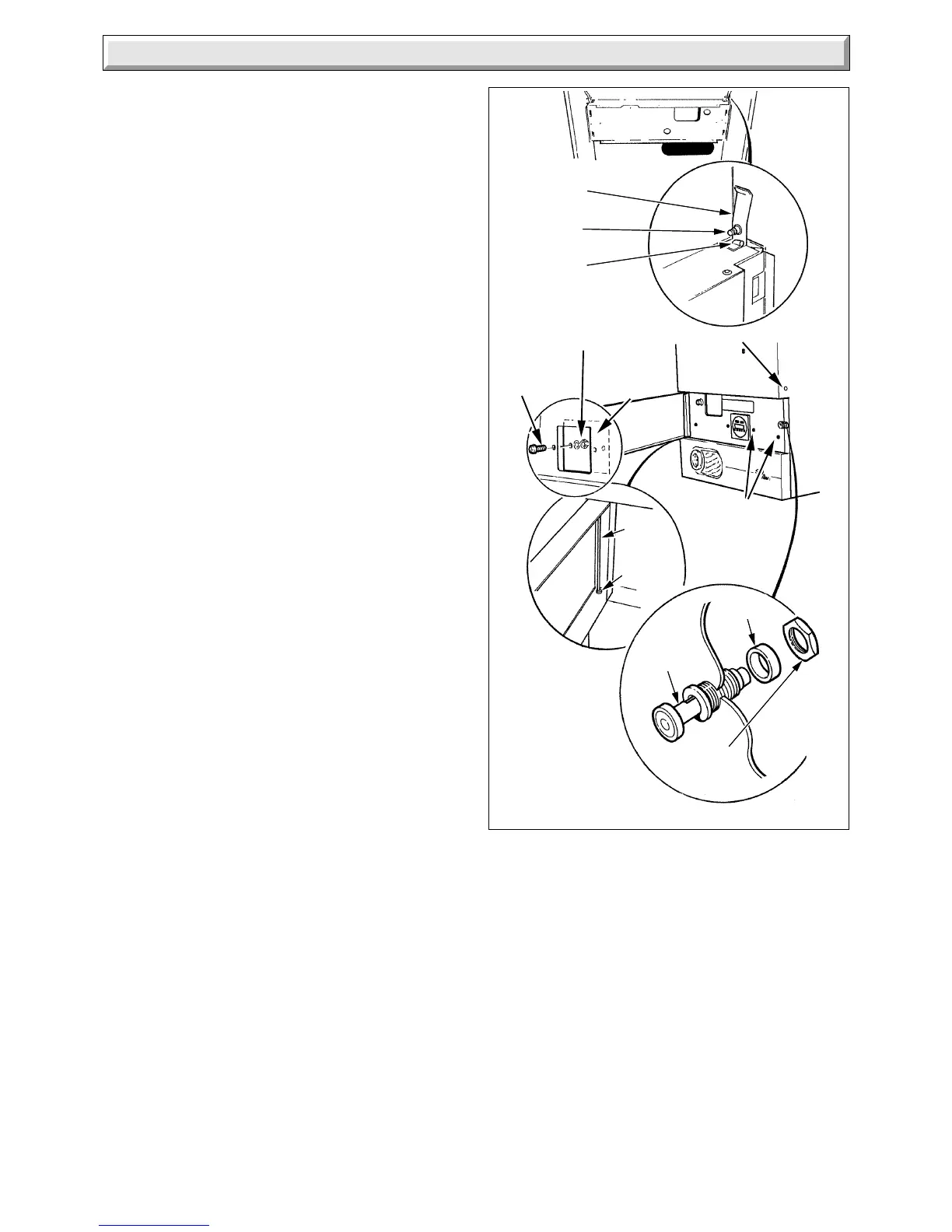

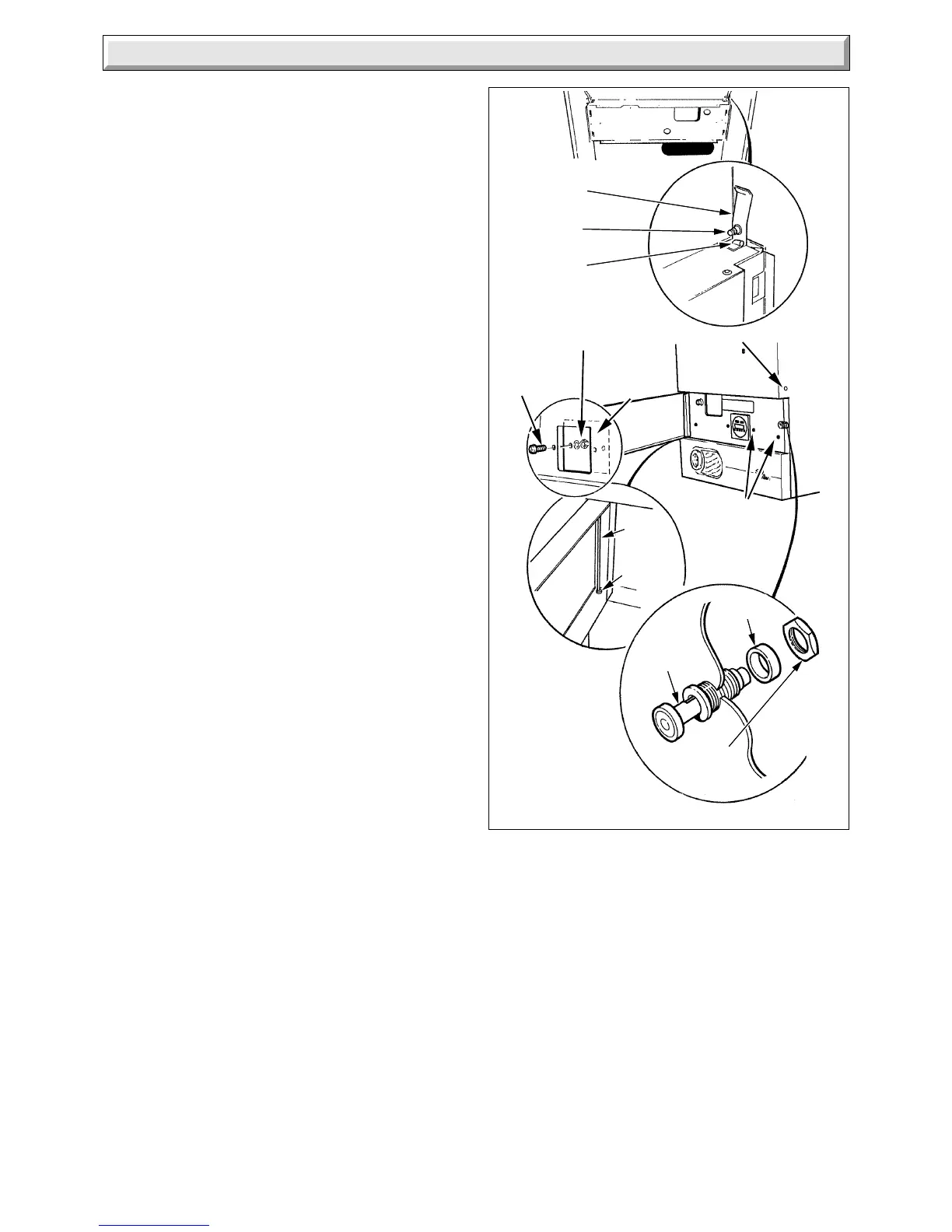

6623

SECURING

NUT

CATCH

ASSEMBLY

SPACER

PLASTIC

BUSH (2

)

HINGE

PIN

HINGE PIN

HINGE PIN RETAINING

BRACKET

BRACKET

SECURING

SCREW

Diagram 11.6

PLASTIC COVERS

COVER

PLATE

NUT &

WASHER(2)

OUTER CASE

SECURING

SCREWS (4)

SCREW (2)

11.10 Heating System - Commissioning

Check that all remote controls and integral clock are calling for

heat.

Fully open all radiator valves, flow control valve “A” and bypass

valve “B”, see diagram 4.2.

Set the heating system in operation and balance the radiators.

Adjust the control valve “A” to achieve the required system

differential temperature between the flow and return.

Turn off all radiators, then adjust bypass valve “B” to achieve the

same temperature difference between the boiler flow and

return.

Refer to Section 4.6 and diagram 4.1 and 4.1A.

Allow the system to reach maximum temperature then switch

off, isolate the boiler from the electrical supply and drain the

system rapidly whilst still hot.

Fill and vent the system as described in Section 11.2 “Filling the

Central Heating Circuit”. Add inhibitor, if applicable, refer to

Section 4.10 “Inhibitor”.

Lower the pressure to the initial cold fill design pressure, using

the external draining tap, close to the boiler, refer Table 2 and

Section 4.11.

Lock or remove the handles from the spindles of flow control

valve “A” and bypass valve “B” to prevent unauthorised

adjustment.

The permanent mains electrical supply to the boiler must not be

switched off whilst the pilot flame is alight.

11.11 Completion

The user control door is designed for left or right hand hinging.

If required the hinge can be moved to the other side to that

supplied, as follows:

Remove the hinge pin bracket securing screw then remove the

hinge pin retaining bracket and holding the door, remove the

hinge pin. Prise out the hinge pin bushes and fit on to the

opposite side of the door, see diagram 11.6.

Remove the screw and nut and fit to the opposite side of the

case. After removing the hinge pin retaining bracket refit the

door and hinge pin. Refit the hinge pin retaining bracket and fit

the securing screw.

Fit the catch assembly, supplied in the loose items pack, see

diagram 11.6.

If required, fit the plastic covers to hide the bracket securing

screws.

Change the position of the “Push” label to suit the new door

opening.

Clock/timer, if fitted, remove the screws, nuts and washers to

release the cover plate, see diagram 11.6.

Stick the casing label to the right hand side of the clock/timer.

Fit the outer case, secure with the four screws, see

diagram 11.6.

Note: Secure with the two outer screws only if there is no clock/

timer fitted.

Set the boiler and any remote heating control to the desired

settings, then close the door.

11.12 Instruct the User

Instruct and demonstrate the lighting procedure, then advise

the user of the efficient and safe operation of the boiler.

Instruct and demonstrate the operation of any heating system

controls.

Advise the user on the use and maintenance of any scale

reducer and pass on any relevant instructional documents.

Advise the user that to ensure the continued efficient and safe

operation of the appliance it is recommended that it is checked

and serviced at regular intervals. The frequency of servicing will

depend upon the particular installation and usage, but in general

once a year should be enough.

Draw attention, if applicable, to the current issue of the Gas

Safety (Installation and Use) Regulations, Section 35, which

imposes a duty of care on all persons who let out any property

containing a gas appliance.

It is the Law that any servicing is carried out by a competent

person.

Advise the user of the precautions necessary to prevent damage

to the system and building in the event of the heating system

being out of use during frost and freezing conditions.

Advise the user that the permanent mains electrical supply

must not be switched off whilst the pilot is alight.

Reminder - Leave these instructions with the user.

Loading...

Loading...