Graham Corporation

24

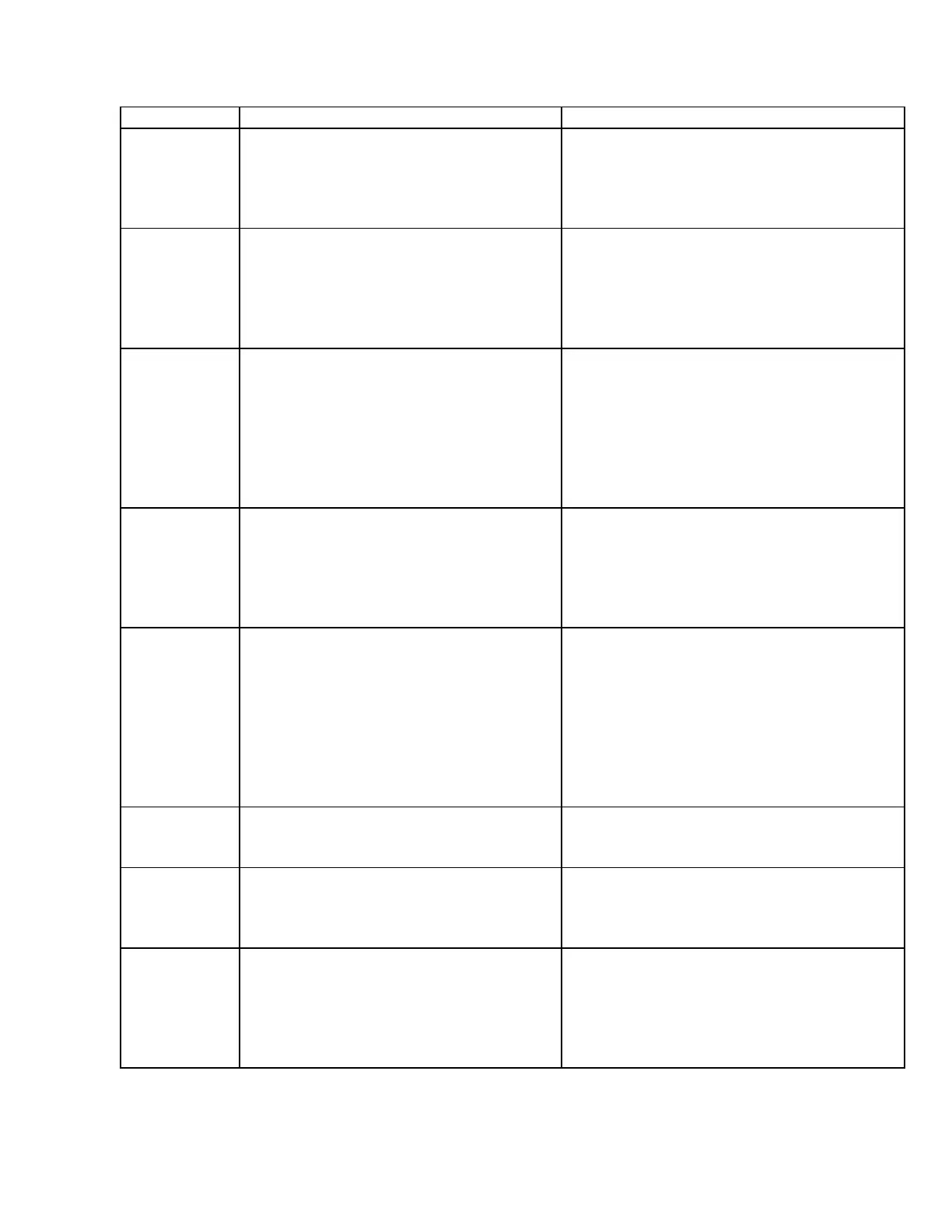

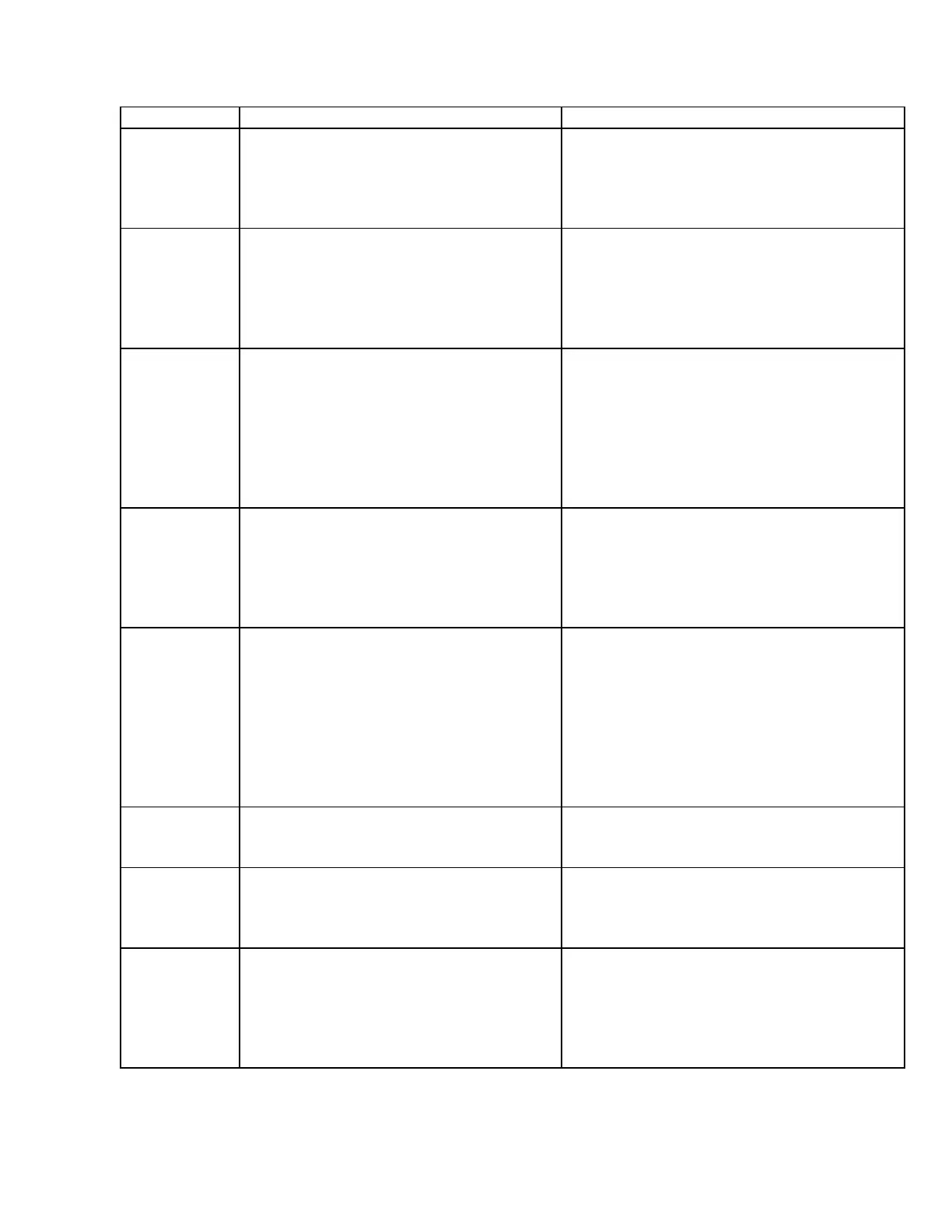

5.8 Troubleshooting Chart

Problem Cause Solution

Reduced

Capacity

•

Speed too low

•

Leak in suction line

•

Service liquid temperature too high

•

Insufficient or excess service liquid

•

Excessive back pressure

•

Check power supply and transmission

•

Repair

•

Check coolant flow & heat exchanger

•

Provide correct flow rate

•

Eliminate cause of back pressure

Excessive

Noise

•

Excessive or insufficient service liquid

•

Shaft misalignment

•

Defective bearing

•

Cavitation

•

Back pressure

•

Adjust flow rate

•

Realign shafts

•

Replace bearing

•

Open attenuation valve or adjust vacuum

relief valve

•

Eliminate cause of back pressure

High Power

Consumption

•

Excessive service liquid

•

Shaft misalignment

•

Excessive back pressure

•

Defective bearing

•

Gland follower too tight

•

Improperly mounted pump

•

High temperature process load

•

Reduce flow rate

•

Realign shafts

•

Eliminate cause of back pressure

•

Replace bearing

•

Loosen gland follower

•

Make sure surface is level and all feet touch

the surface, shim if necessary.

•

Check conditions upstream of pump

Overheating

•

Service liquid temperature too high

•

Insufficient service liquid

•

Shaft misalignment

•

Defective bearing

•

Gland ring too tight

•

Check coolant flow & heat exchanger

•

Provide correct flow rate

•

Realign shafts

•

Replace bearing

•

Loosen gland ring, check packing coolant

flow

Vibration

•

Shaft misaligned

•

Pump or baseplate not properly anchored

•

Defective bearing

•

Improperly mounted pump

•

Cavitation

•

Back pressure

•

Excessive service liquid

•

Realign shafts

•

Anchor

•

Replace bearing

•

Make sure surface is level and all feet touch

the surface, shim if necessary.

•

Open attenuation valve or adjust vacuum

relief valve

•

Eliminate cause of back pressure

•

Provide correct flow rate

Excessive

Gland

Leakage

•

Worn packing

•

Loose gland

•

Gland coolant pressure too high

•

Replace packing

•

Tighten gland follower

•

Reduce pressure

Abnormal

Bearing Wear

or Failure

•

Shaft misalignment

•

Piping load on pump flange

•

Mechanical seal leakage

•

Shaft flinger missing

•

Realign shafts

•

Support connecting pipe work

•

Replace seals

•

Replace flinger

Shaft Will Not

Turn or

Partially

Seizes

•

Scale build-up

•

Foreign object in pump

•

Piping load on pump flange

•

Improperly mounted pump

•

Soft Foot

•

Descale pump

•

Remove foreign object

•

Support connecting pipe work

•

Make sure surface is level and all feet touch

the surface, shim if necessary.

•

Correct pump / motor mounting

Table 3

Loading...

Loading...