Graham Corporation

4

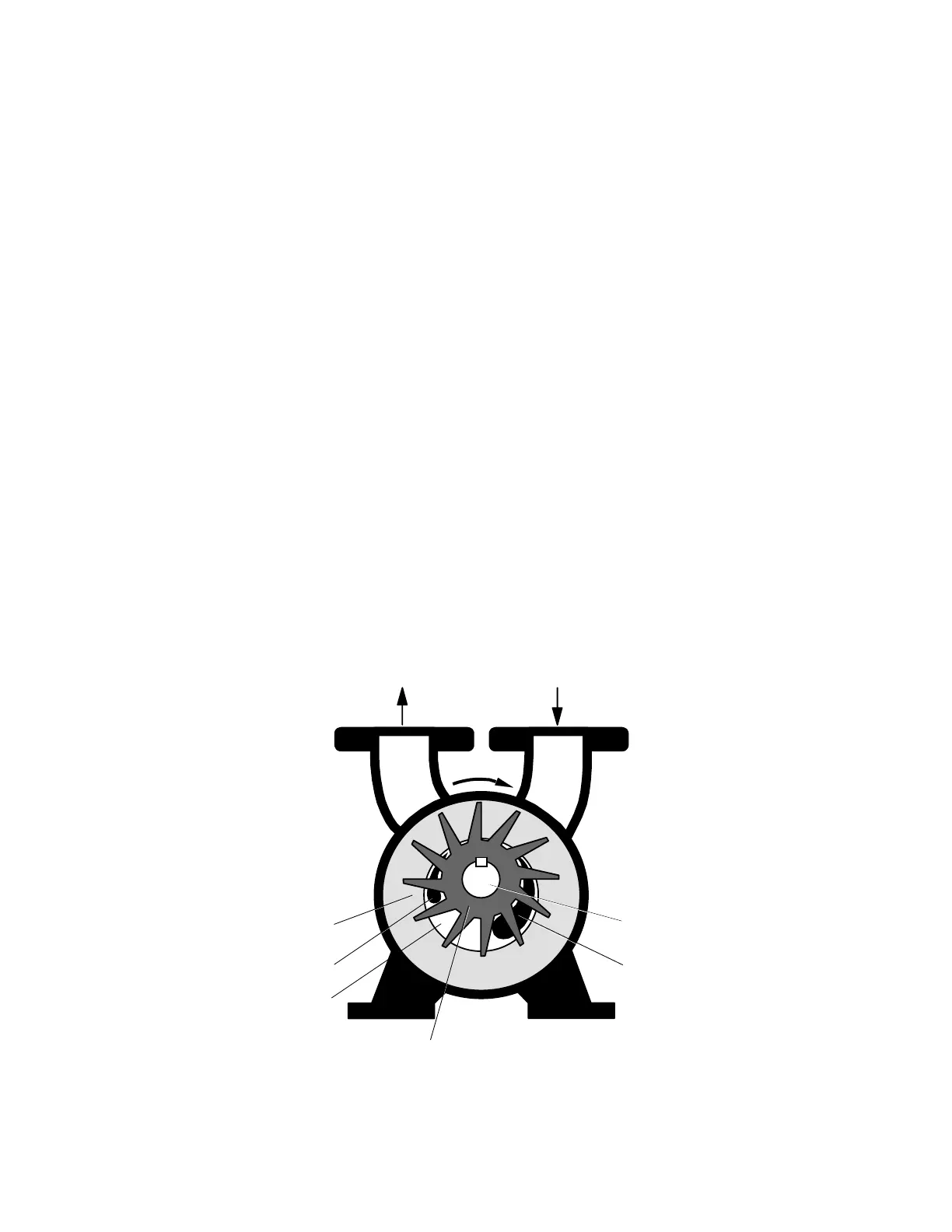

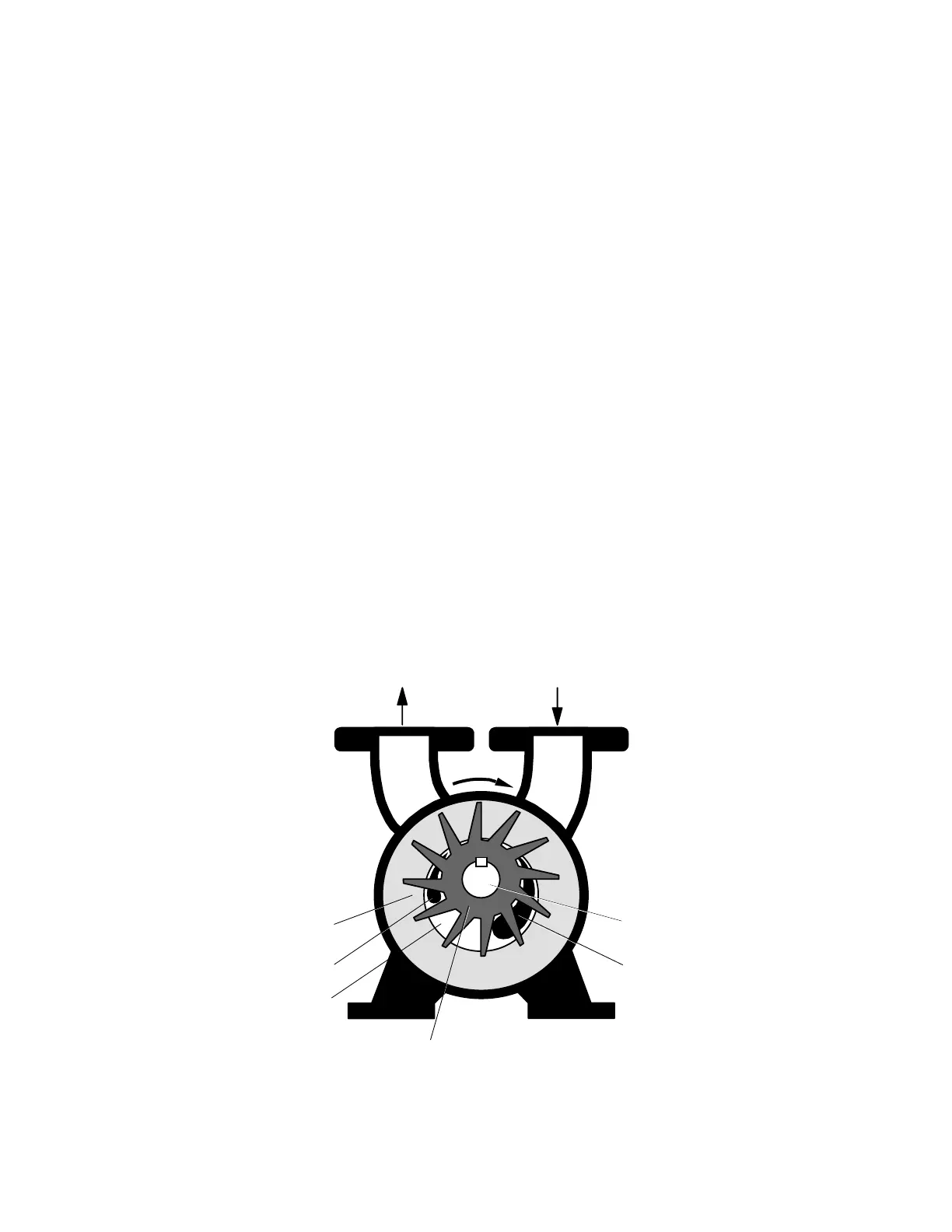

1.2 General Description and Principle of Operation

Graham Vacuum Pumps and Compressors are of the liquid ring type. Single and two stage

pumps are available in a wide range of sizes and materials. These options are listed in the

Graham Sales Bulletins. The major component of the Graham pump is a multi-bladed rotating

assembly positioned eccentrically in a cylindrical casing. (See Figure 1) This assembly is

driven by an external source, normally an electric motor. Service liquid (usually water) is

introduced into the pump. As the impeller rotates, centrifugal force creates a liquid ring which

is concentric to the casing. At the inlet, the area between the impeller blades (buckets) increase

in size, drawing gas in. As the impeller continues to rotate toward the discharge, the impeller

bucket area decreases in size, compressing the gas. This gas, along with the liquid from the

pump, is discharged through the outlet nozzle. The service liquid is separated from the gas and

cooled for reuse in the pump or sent to a drain. In addition to being the compressing medium,

the liquid ring performs two other important functions:

1) It absorbs the heat generated by compression, friction, and condensation of

the incoming vapor.

2) It absorbs and washes out any process contaminants entrained in the gas.

A continuous supply of service liquid is necessary to limit the temperature rise in the pump

caused by the heat of compression, friction, and condensation. Any excessive rise in

temperature will have a detrimental effect on performance, reducing the capacity and degree of

vacuum attainable. Installation schematics for the supply of the service liquid and for the

separation of the gas and liquid discharged from the pump are shown in Section 2.

Gas

Inlet

Gas and

Li

uid Outlet

Shaft

Suction Port

Impeller

Gas

Dischar

e Port

Li

uid Rin

Rotation

Figure 1

Loading...

Loading...