Instruction of the GMV D.C. inverter

14

6 Filling of Refrigerant and Test Run

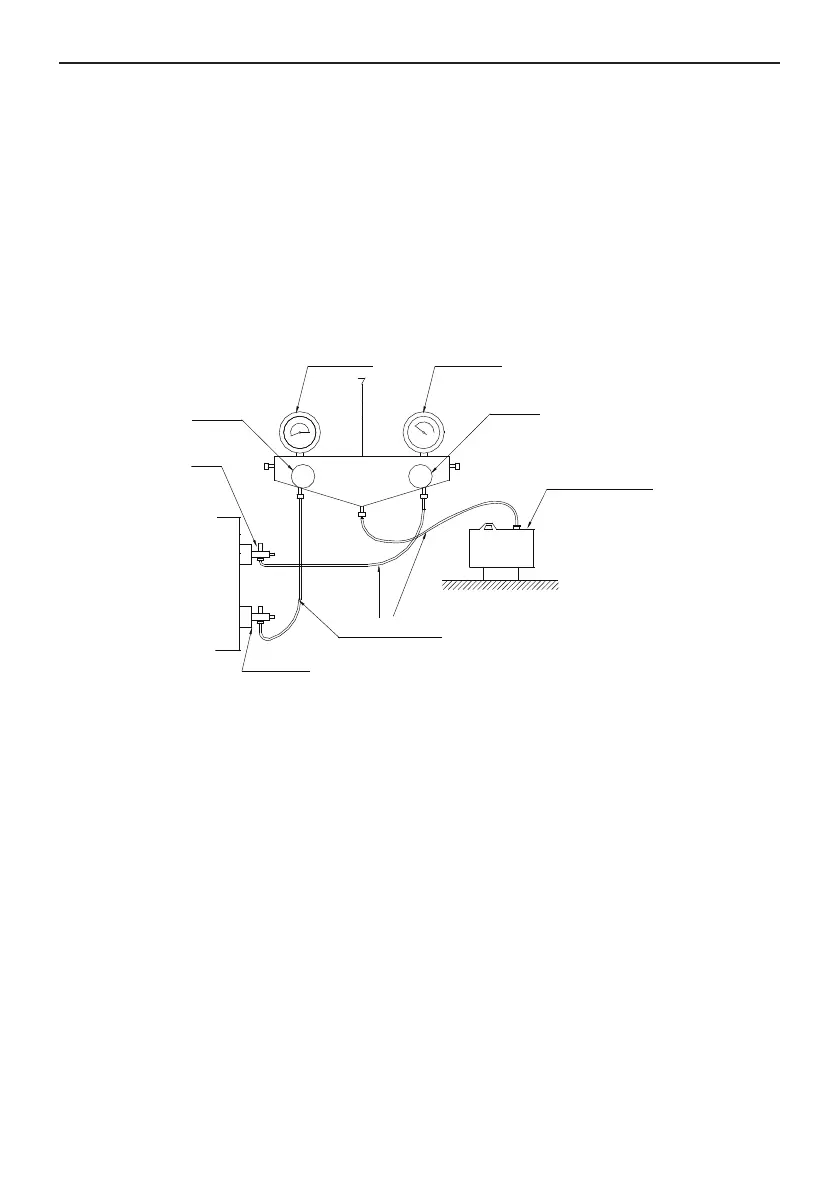

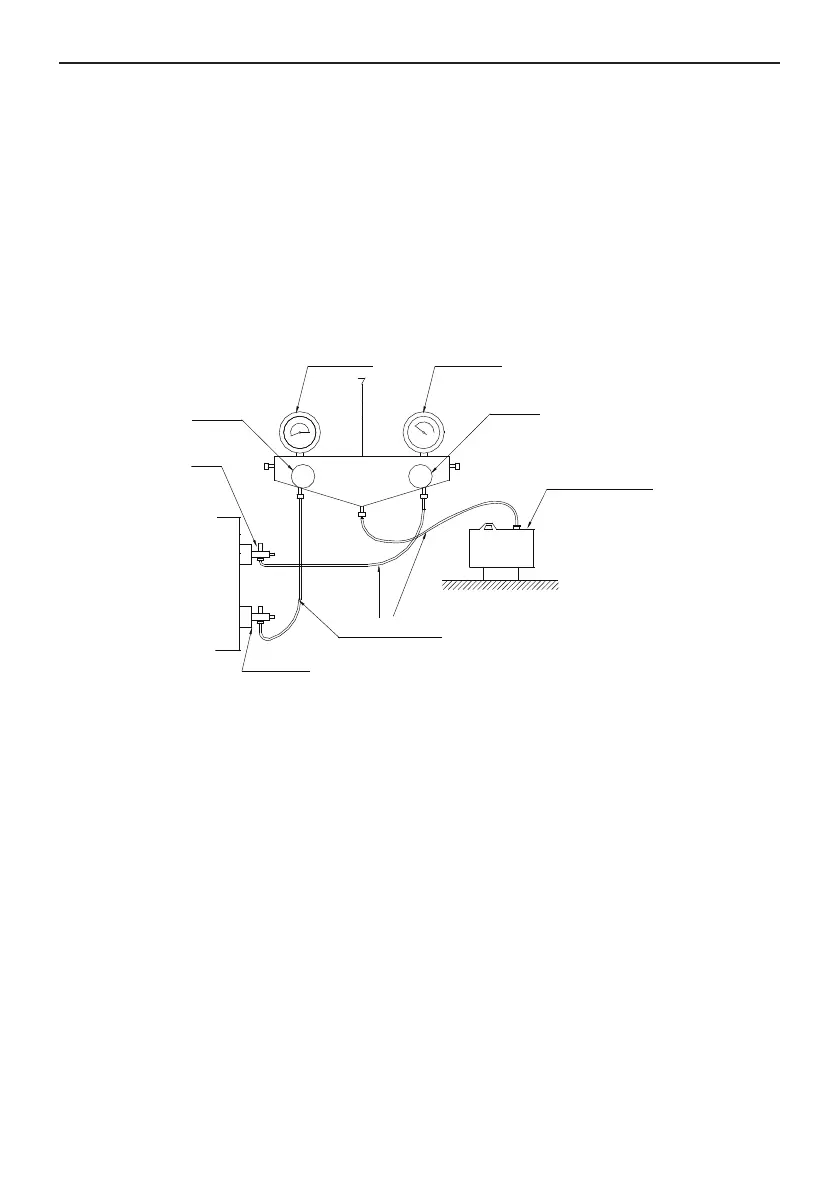

6.1 Filling of Refrigerant

1). Before shipped out from manufacturer, the outdoor unit has been lled with refrigerant.

Additional refrigerant may be lled when carrying out site connection of pipelines.

2). Check the liquid valve and the gas valve of the outdoor unit. The valves shall be

completely shut off.

3). Connect a vacuum pump to the liquid valve and the gas valve of the outdoor unit to

remove air from the inside of the indoor unit and the connecting pipe. Refer to the

following gure:

"LO"Knob

"HI"Knob

Vacuuming pump

Connection hose

Gas valve

Liquid valve

4). After conrming that there is no leakage from the system, when the compressor is not in

operation charge additional R410A working uid with specied amount to the unit through

the lling opening of the liquid pipe valve of the outdoor unit.

6.2 Calculating Mass of Additional Refrigerant

Note:

① .

The mass of refrigerant in the system when delivered from manufacturer does not include

the mass of additional refrigerant needed by the piping connecting the outdoor unit and the indoor

unit.

② .

As the length of the connecting pipe is decided on site, the amount of additional refrigerant

shall be decided depending on the size and the length of the liquid pipe used on site.

③ .

t is not needed to add refrigerant if the total length of liquid pipe is within 50m.

Loading...

Loading...