Air-to-water Heat Pump

31

MONOBLOC

TYPE

(6) If a leak is suspected, all naked ames shall be removed / extinguished. If a leakage of refrigerant is found

which requires brazing, all of the refrigerant shall be recovered from the system, or isolated (by means of

shut o valves) in a part of the system remote from the leak. Oxygen free nitrogen (OFN) shall then be

purged through the system both before and during the brazing process.

Note

Before and during operation, use an appropriate refrigerant leak detector to monitor the operation area and

make sure the technicians can be well aware of any potential or actual leakage of inammable gas. Make sure the

leak detecting device is applicable to inammable refrigerant. For example, it should be free of sparks, completely

sealed and safe in nature.

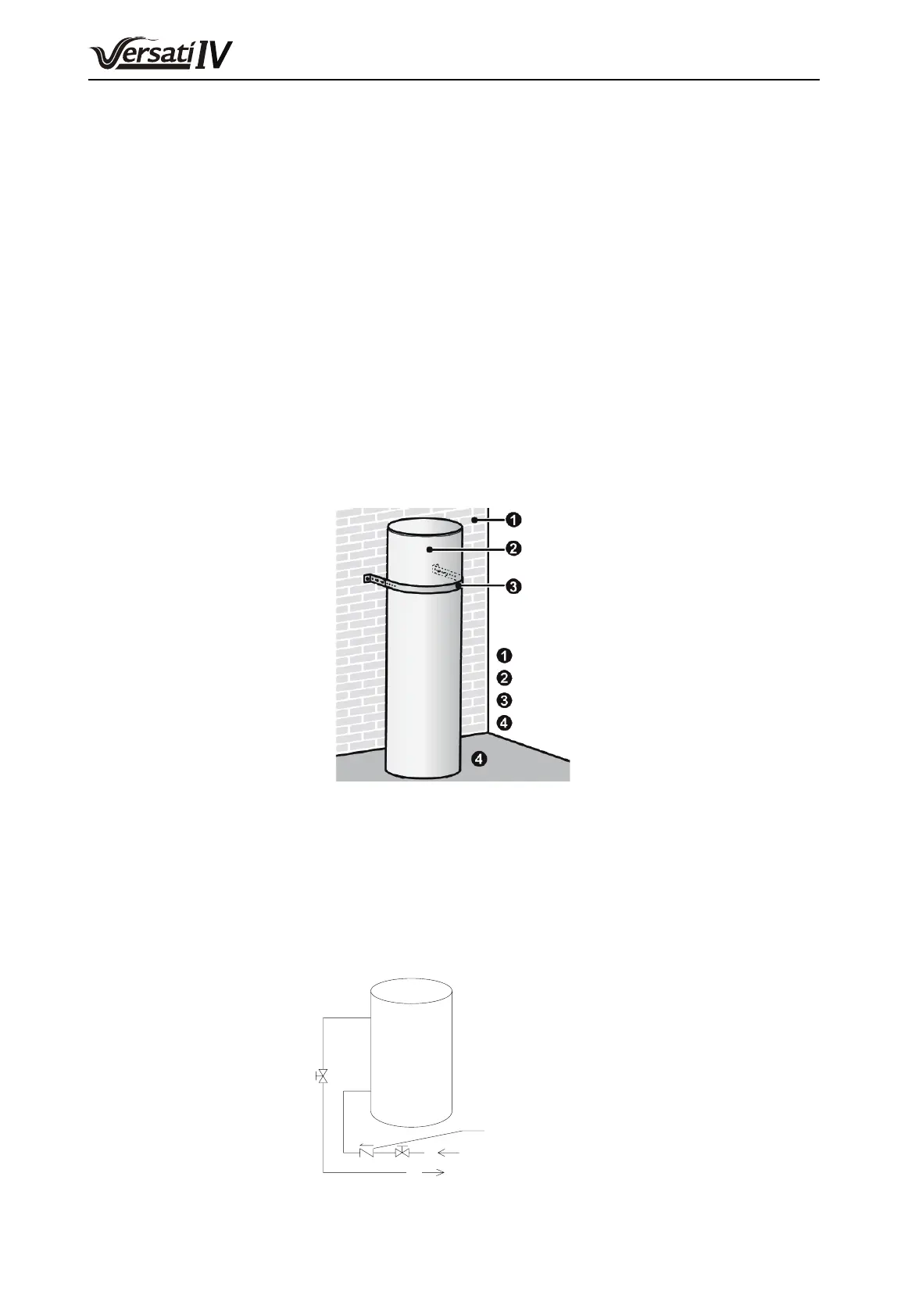

16. Installation of Insulated Water Tank

16.1 Installation measure

The insulated water tank should be installed and keep levelly within 5m and vertically within 3m from the indoor

unit. It can be installed in the room.

Standing water tank must be installed vertically with the bottom on the ground, never suspended. Installation

place must be rm enough and the water tank should be xed on the wall with bolts to avoid vibration, as shown in

the following gure. Weight capacity of water tank during installation should also be considered.

Wall

Water Tank

Fixing Strap

Floor

The minimum clearance from the water tank to combustible surface must be 500mm.

There should be water pipe, hot water joint and oor drain near the water tank in favor of water replenishment,

hot water supply and drainage of water tank.

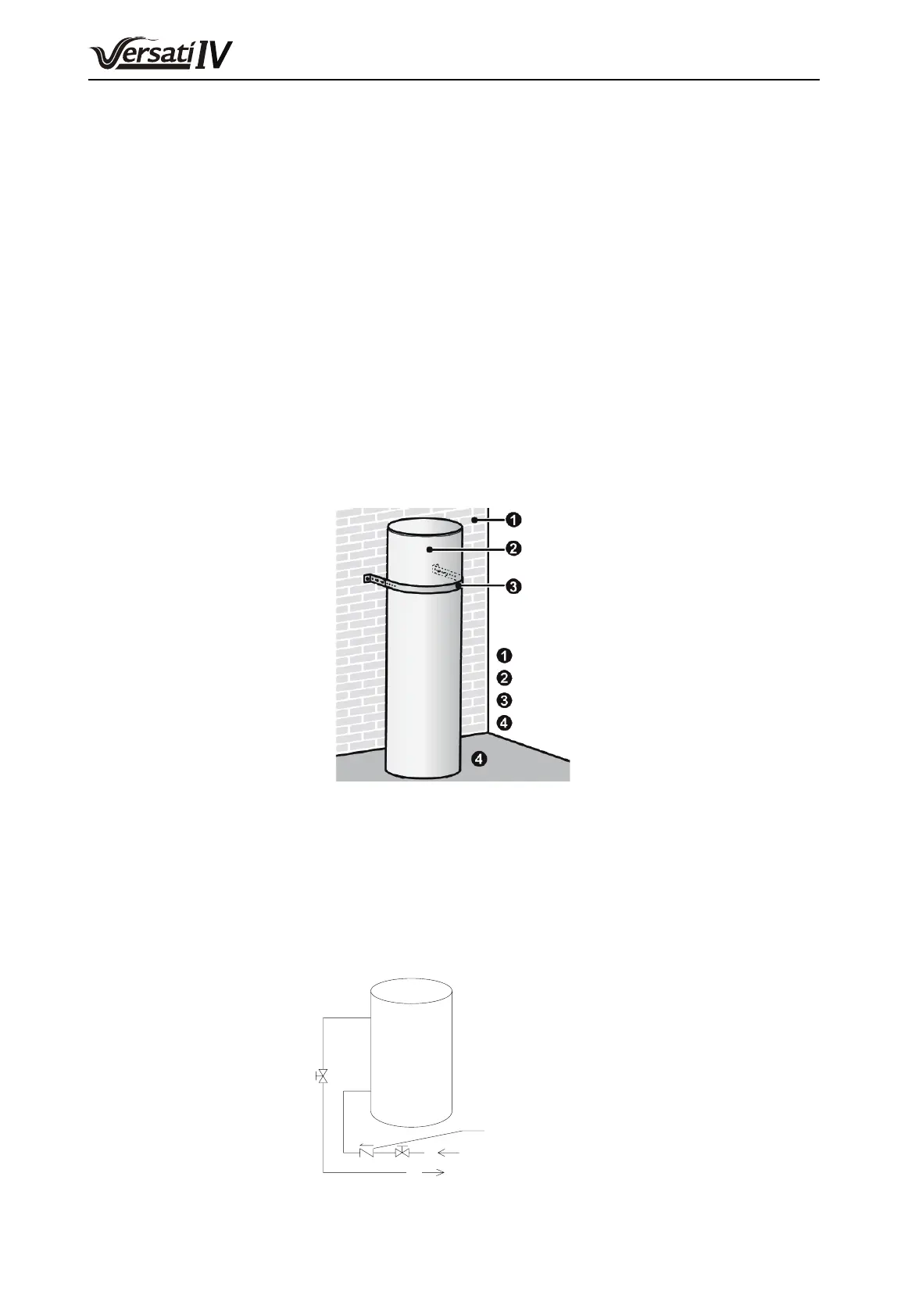

Connection of inlet/outlet waterway: Connect the safety check valve attached with the unit (with the arrow on it

pointing at the water tank) with the water inlet of water tank with PPR pipe according to the following gure, sealing

with unsintered tape. The other end of the safety check valve should connect with tap water joint. Connect the hot

water pipe and water outlet of water tank with PPR pipe.

Tap water

Safety check valve

Loading...

Loading...