3.6 PTC

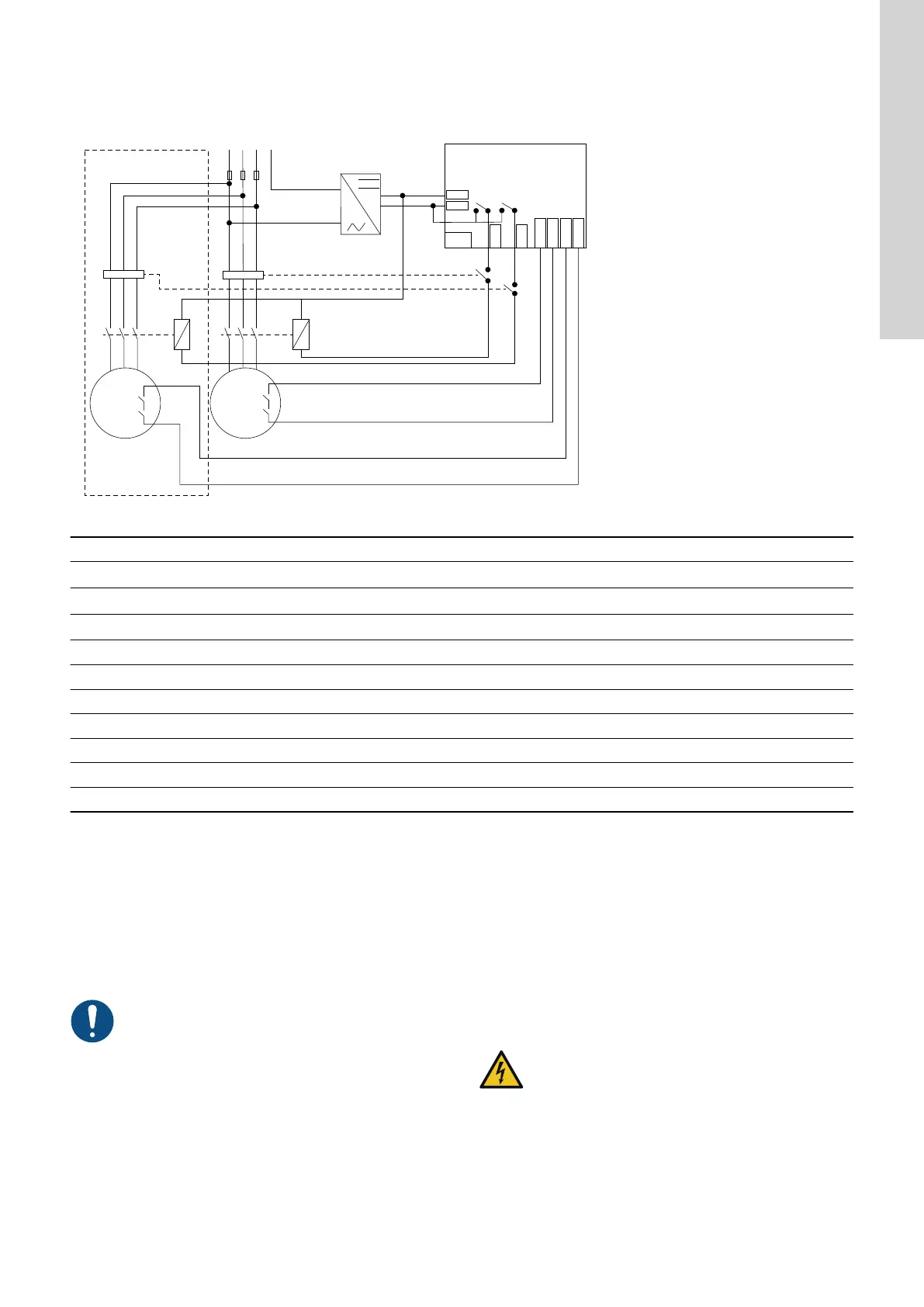

The control unit offers a thermal protection, PTC, for the connected

motors.

IO 242 is a subassembly ensuring safe stop of the motors. The PTC

function fulfills performance level C, category 1, according to ISO

13849. The drawing shows the recommended PTC wiring for IO

242.

1 2 3

5

MM

24 V

GND

COM

PTC 1A

PTC 1B

PTC 2A

PTC 2B

REL 1

REL 2

MM

IO 242

4

6

7

7

9

9

8

8

TM075363

Pos. Description

1

L

1

2

L

2

3

L

3

4 N

5 Power supply

6 IO 242

7 Motor relay

8 Motor protection

9 PTC

M Motor

Related information

2.3.1 Connecting the power supply

5. Technical data

4. Servicing the product

The module cannot be serviced.

• Contact Grundfos. If the module is faulty, it must be replaced

4.1 Inspecting the product functions

You must perform an inspection every fifth year to ensure

full functionality of the product.

Recommended inspection procedure:

1. Ensure that the motor is allowed to start, i.e. the motor is cold

and there is enough water in the pit.

2. With the PTC sensors connected, start the motor and observe

that it runs.

3. Disconnect power from the panel.

4. Disconnect the PTC sensors from IO 242.

5. Reconnect power to the panel.

6. Attempt to start the motor and observe that it does not start,

and ensure that an alarm for high motor temperature is

present.

7. Disconnect power from the panel, and reconnect the PTC

sensors to IO 242.

8. Perform a visual inspection to ensure that the PTC wiring is

correct.

9. Reconnect power to the panel.

4.2 Replacing the IO module

WARNING

Electric shock

Death or serious personal injury

‐ Switch off the power supply before making any

electrical connections.

‐ Make sure that the power supply cannot be switched

on accidentally.

1. Switch off the power supply to the product and

other components with external supply.

2. Write down the terminal connection of each wire to ensure

correct reconnection.

3. Disconnect all wires.

4. Press the module up gently (1).

9

English (GB)

Loading...

Loading...