14

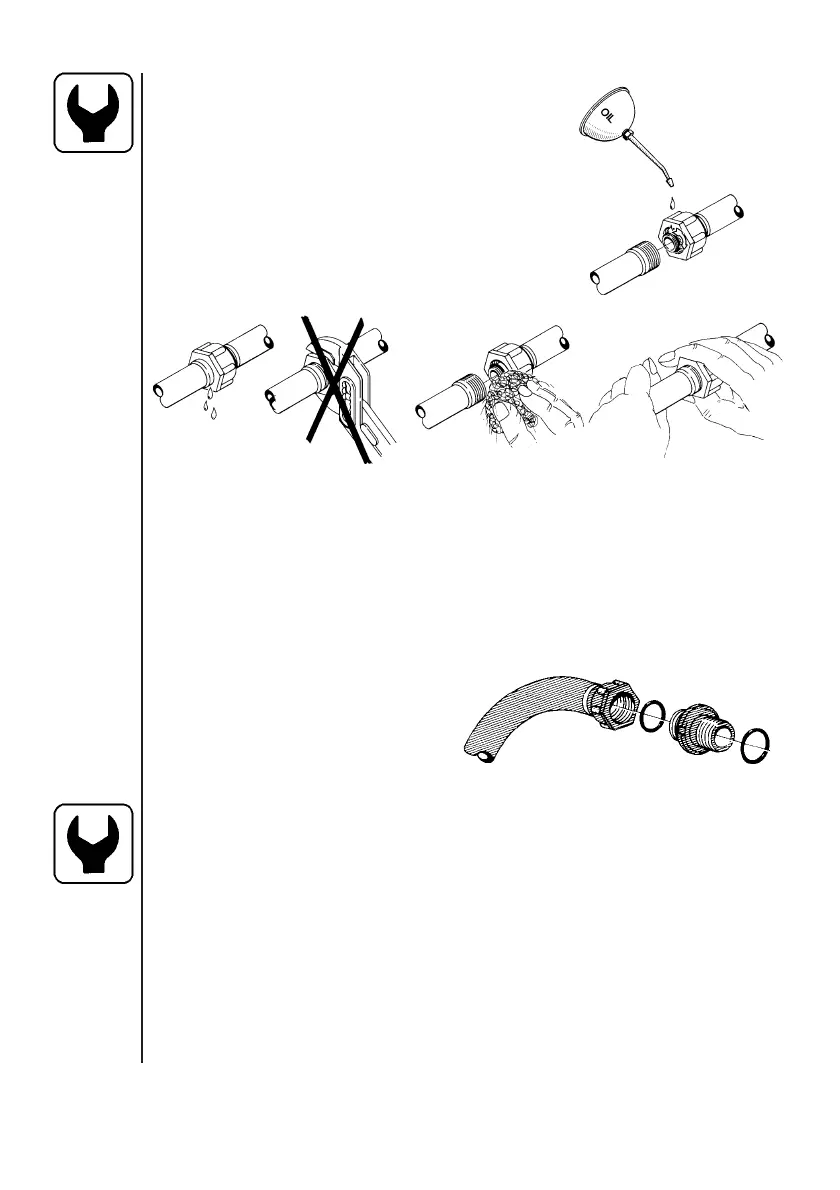

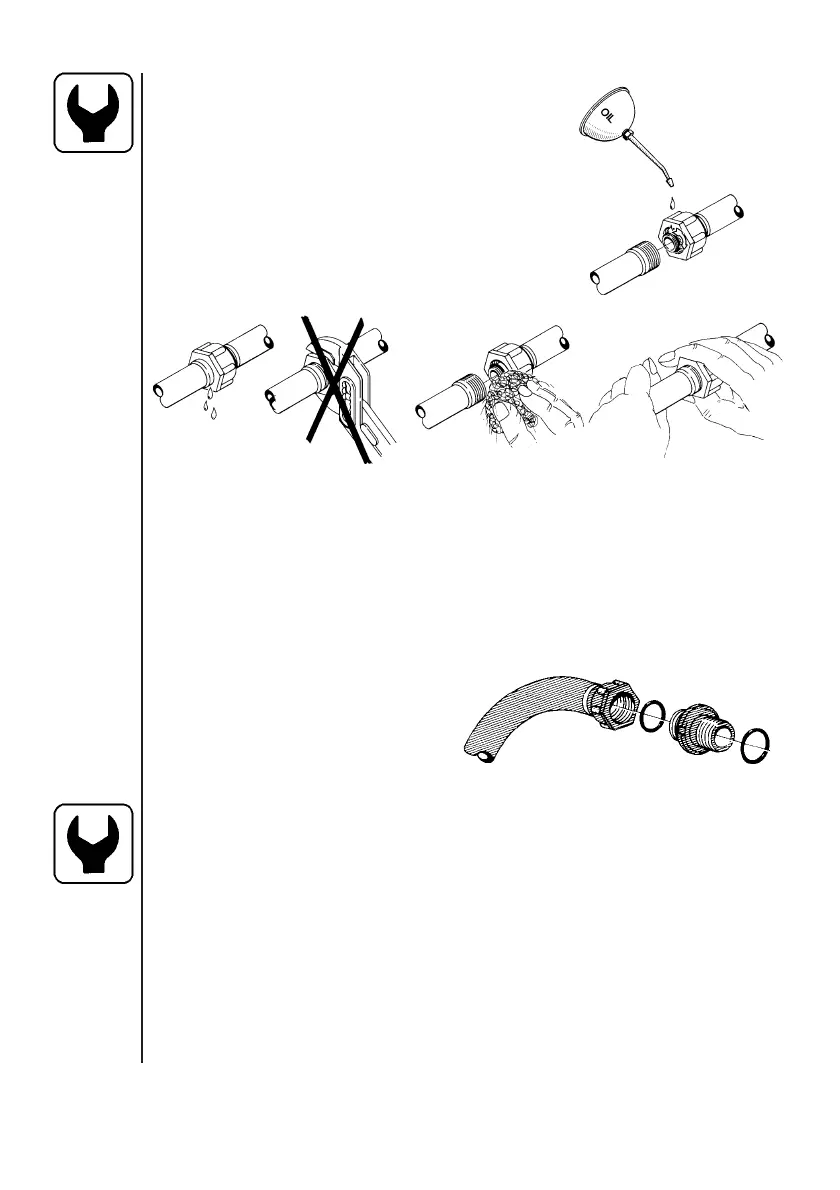

Nozzle tubes and fittings

Poor seals are usually caused by;

• missing O-rings or gaskets

• damaged or incorrectly seated O-rings

• dry or deformed O-rings or gaskets

• foreign bodies

Therefore, in case of leaks: DO NOT over-tighten. Disassemble, check

condition and position of O-ring or gasket, clean lubricate and reas-

semble.

For radial connections only hand tighten them.

The O-ring must be lubricated ALL THE WAY ROUND before refitting.

For face connections, a little

mechanical leverage may be

used.

Off-season storage

When the spraying season is over you should devote some extra time

to the sprayer before it is stored.

Hoses

Check that none of the hoses are caught or have sharp bends.

A leaky hose can give an annoying delay in the middle of the spraying

job. Therefore check all the hoses and change if there is any doubt

about the durability.

Loading...

Loading...