9

spraying again. Unauthorized persons and animals must not have

access to the sprayer under these circumstances.

If the product applied is corrosive, it is recommended to coat all metal

parts of the sprayer before and after use with a suitable rust inhibitor.

Remember: Clean sprayers are safe sprayers.

Clean sprayers are ready for action.

Clean sprayers cannot be damaged by pesticides

and their solvents.

Filters

Clean filters ensure :

• Sprayer components such as valves, diaphragms and operating unit

are not hindered or damaged during operation.

• Nozzle blockages do not occur whilst spraying.

• Long life of pump. A blocked suction filter will result in pump

cavitation.

Suction filter

The main filter protecting sprayer components is the suction filter.

Check it regularly.

The sprayer has a suction filter placed in the top of the tank.

BK Pressure filter

The BK operating unit has an built-in pressure filter. Unscrew the filter

bowl to inspect and clean the filter.

Alternative filters are available.

See section on Technical specifications - Filters and nozzles.

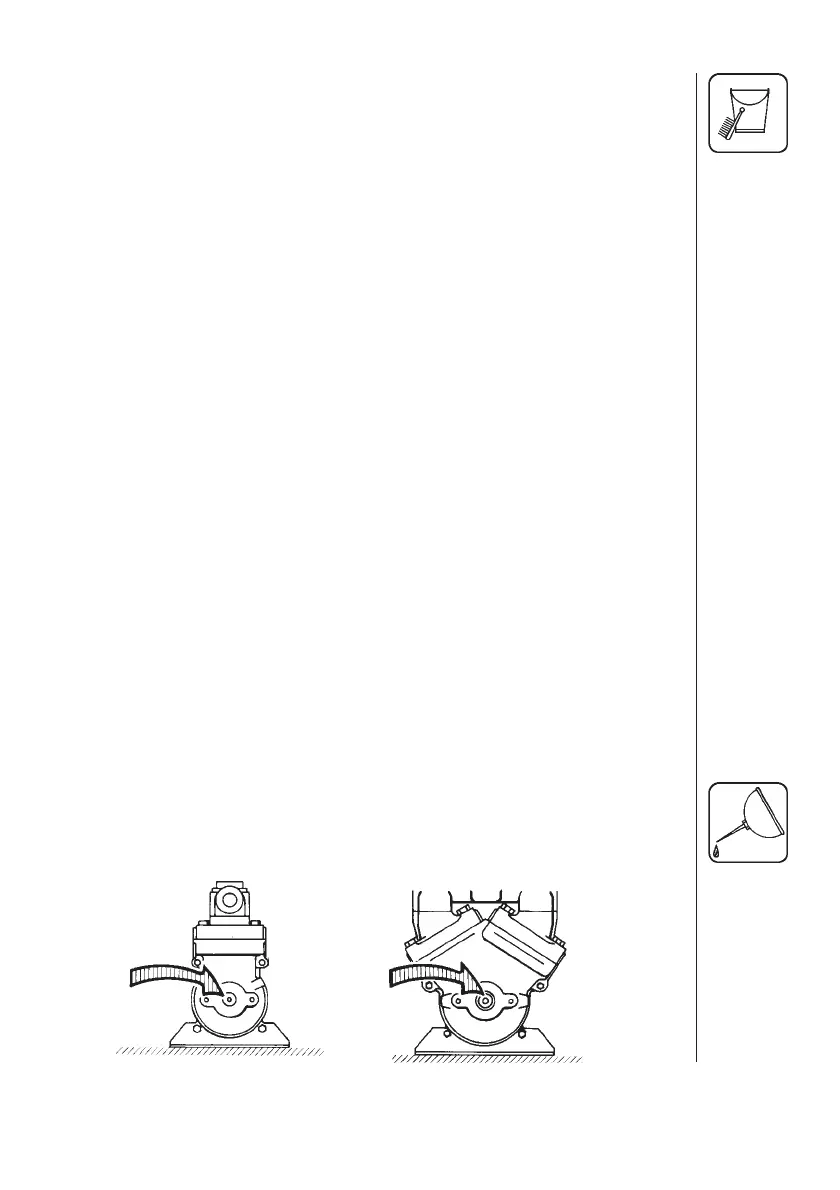

Lubrication

After 40 hours’ operation the diaphragm pump is lubricated with ball

bearing grease Lithium No. 2.

Loading...

Loading...