24

PP38+ Pellet Stove

Pellet nes may accumulate in the feeder body over

a period of time; therefore, a yearly inspection and

cleaning of this area must be performed.

To clean out nes:

1. Remove the rear cover panels.

2. Remove wing nut and feeder cover on the

side of the feeder.

3. Use a vacuum cleaner to remove all nes.

4. Reinstall feed cover, wing nut, and rear

cover panels.

5/16" Hex Head

Screws (2 on

each side)

5/16" Hex Head

Screws (2 on

each side)

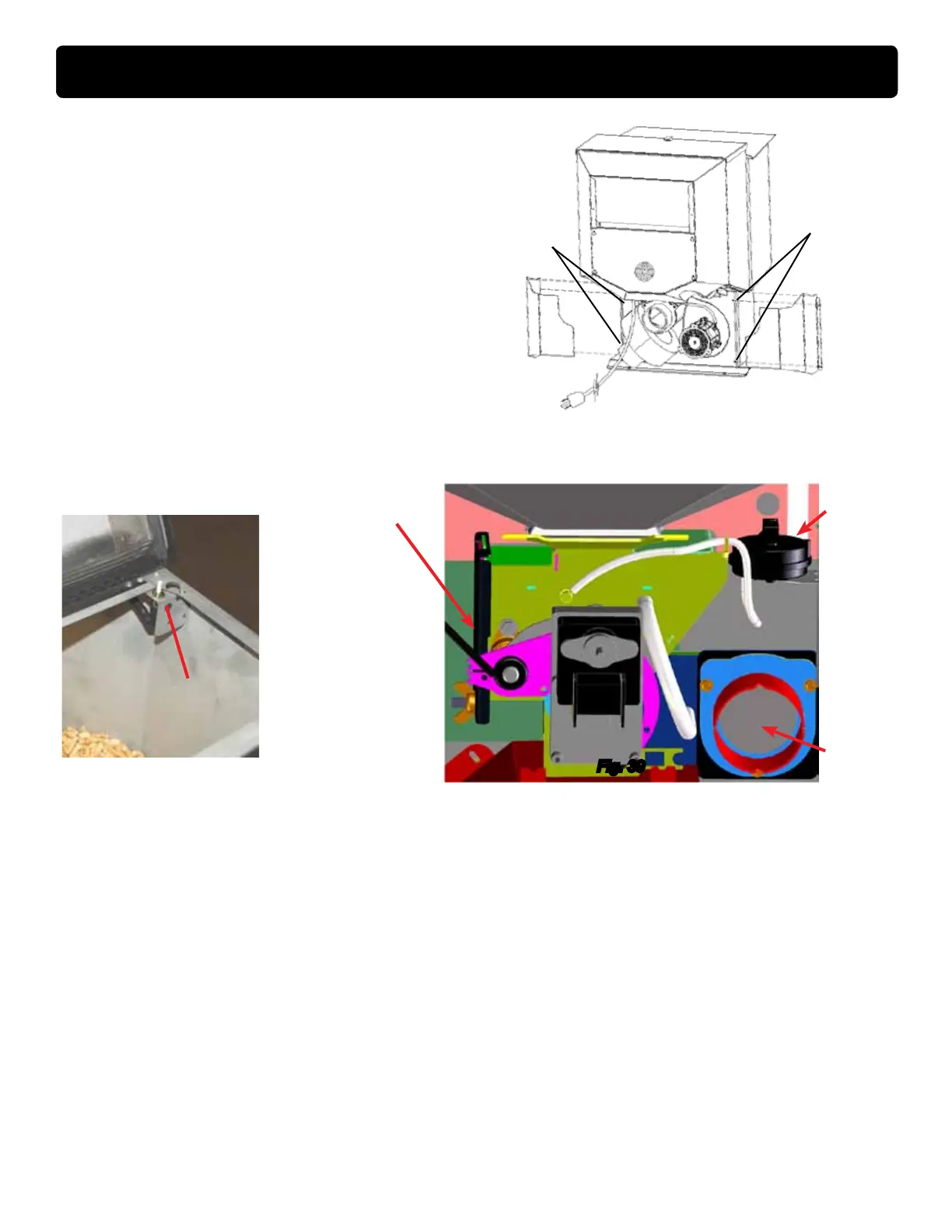

The low draft sensor which is a vacuum differential switch, monitors the negative pressure (draft) in the rebox

through a port on the rear of the feeder. Poor draft will result in an interruption of power to the feeder motor. Poor

draft can be caused by blockage in the exhaust, excessive build-up on the combustion blower fan blades, a failed

combustion blower, or a door or other opening to the rebox not sealed properly. The hopper lid position switch,

located in the right rear corner of the hopper opening, will also interrupt power to the feeder if the hopper lid is not

closed properly. The circuit board is monitoring the position of these switches. During a feed cycle, if either of these

switches were to open, the feed motor light on the control will stay illuminated with the power being interrupted

by the switch. If the switch opens when the cycle is at rest, the power light for the feed motor will not illuminate.

Be sure all doors, including the hopper lid, are securely closed when operating the appliance.

Hopper Lid

Position Switch

Pellet Fines may

build up in this

area

Low

Draft

Sensor

Air

Intake

Flapper

Fig. 39

Loading...

Loading...