30

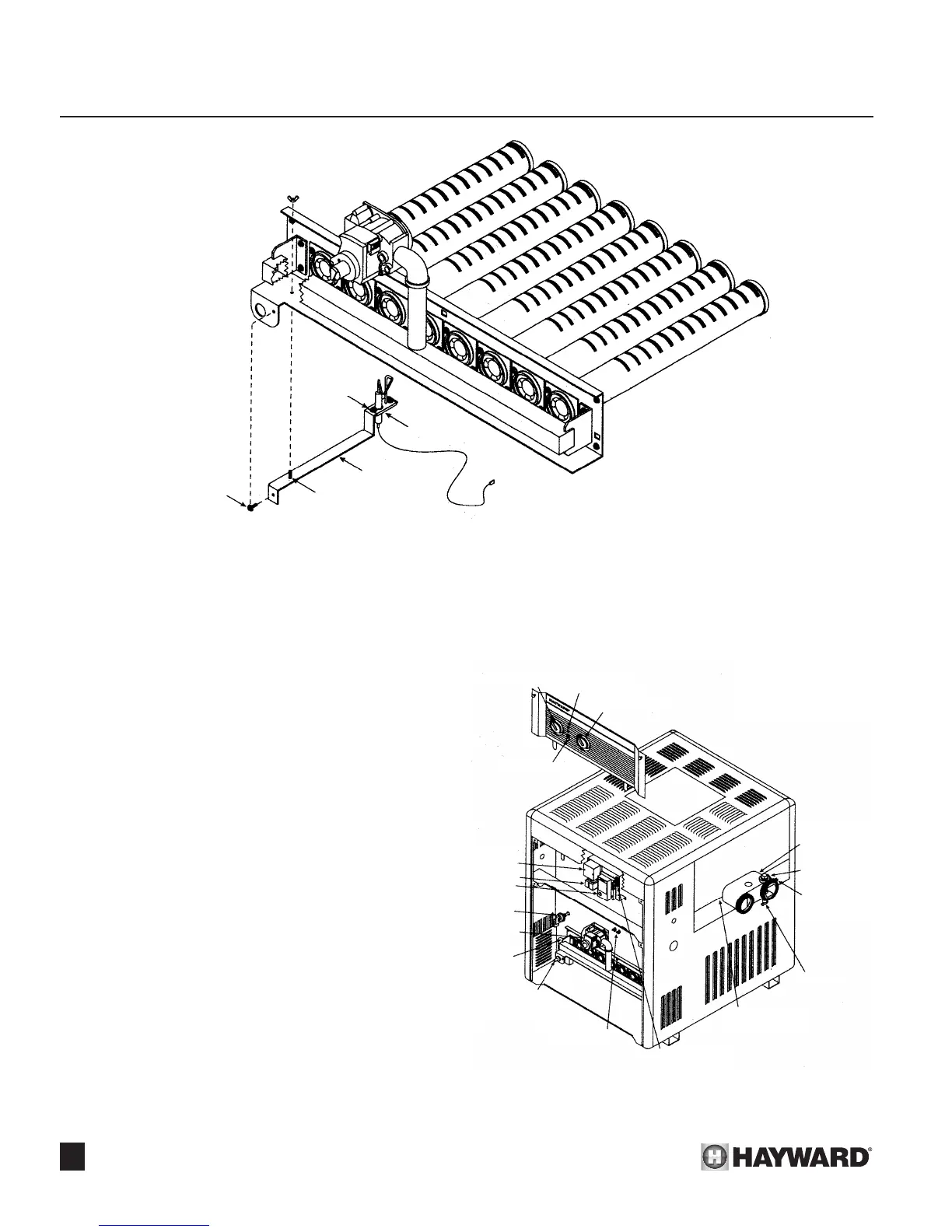

CLINCH STUD

IGNITOR

BRACKETS

SECURING SCREW

2 SCREWS

SHOWN WITHOUT SURROUNDING

HEATER CABINET FOR CLARITY

SECTION 6. QUALIFIED TECHNICIAN - MAINTENANCE/SERVICING

Ignitor assembly removal: (Electronic Ignition Heater Only) (See Figure 49.)

1. Disconnect the electrode/sensor wire from the ignition module.

2. Remove screw securing ignitor bracket to clear locating

stud and remove assembly from heater.

3. To service or replace ignitor remove two screws securing ig-

nitor to ignitor bracket and disconnect electrode ignitor wire.

4. Recheck spark gap (9/64”).

5. Reverse the above procedures for installation.

Main burner orices:

The main burner orices can be removed from the mani-

fold with a 7/16” wrench without having to remove the burner

assembly from the heater. After cleaning or replacing orices

re-install in manifold being careful not to overtighten as a leak

may result.

! CAUTION: Do not enlarge orice holes.

Gas conversion:

The factory installed gas train, where appropriate, may

be changed from natural gas to propane or from propane to

natural gas, using the appropriate conversion kit, available

from the factory. Gas conversions are to be performed only

by a qualied agency. Detailed instructions are included with

each kit.

! NOTE: Conversion kits are not available in Canada.

Conversions must be done by the conversion station at Hay-

ward Pool Products Canada, Inc.

Figure 49: Ignitor Assembly Removal

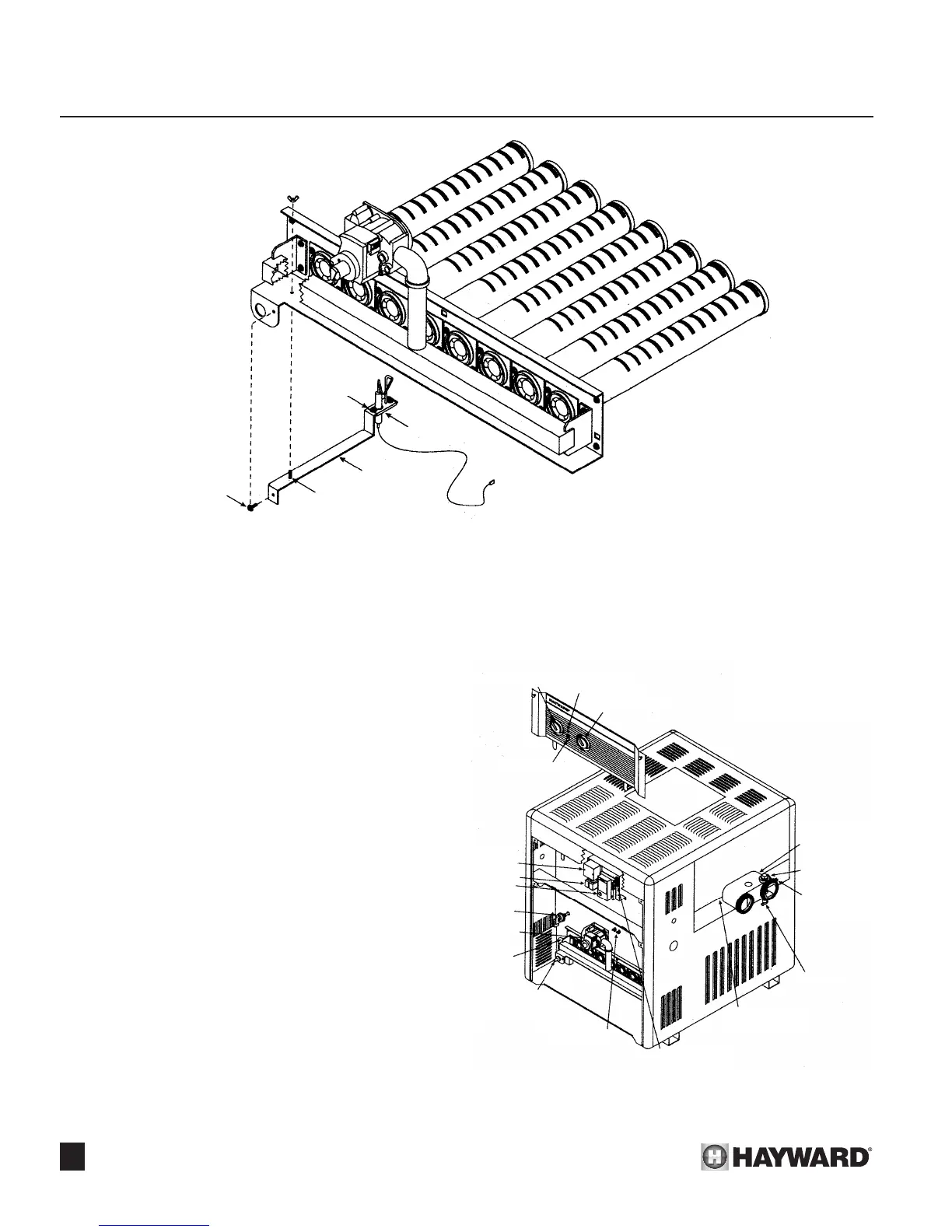

SPA THERMOSTAT

POOL THERMOSTAT

SYSTEM SWITCH

BY-PASS VALVE

(INSIDE FRONT

HEADER)

FLOW CONTROL

THERMOSTAT

(ON FRONT HEADER)

LED LIGHTS

DRAIN VALVE

HIGH LIMITS

(ON FRONT AND

REAR HEADER)

THERMOSTAT

BULB WELL(S)

ON FRONT HEADER

TERMINAL BLOCK

TEMPERATURE

LIMITER SWITCHERS

FIELD WIRING

JUNCTION BOX

TRANSFORMER

GAS VALVE

CONTROL

MODULE

PRESSURE

SWITCH

CLICKLITE

TM

(MILLIVOLT

UNITS ONLY)

PILOT

ASSEMBLY

(ON LEFT SIDE

OF BURNER

ASSEMBLY)

Figure 50: Control Locations

Loading...

Loading...