8

English

18. Do not switch the unit on while the chain case is

attached.

Injury may occur.

19. Ensure there are no nails and other foreign objects in

the material.

If the saw chain impact on the nail etc., injury may

occur.

20. To avoid the guide bar becoming entangled with the

material when chopping on a verge or when subject to

the weight of material while cutting, install a supporting

platform close to the cutting position.

If the guide bar becomes entangled, injury may occur.

21. If the unit is to be transported or stored after use, either

remove the saw chain, or attach the chain cover.

If the saw chain comes into contact with your body,

injury may occur.

22. Adequately care for the unit.

○ To ensure work can be performed safely and effi ciently,

care for the saw chain to ensure it provides optimal

cutting performance.

○ When replacing the saw chain or guide bar, maintaining

the body, fi lling oil etc., follow the instruction manual.

23. Ask the shop to repair the unit.

○ Do not modify this product, since it already complies

with the applicable safety standards.

○ Always refer to your Hitachi Authorized Service Center

for all repairs.

Attempting to repair the unit yourself may result in an

accident or injury.

24. When not using the unit, ensure it is properly stored.

Drain off the chain oil, and keep in a dry place out of

reach of children or a locked location.

25. If the warning label is no longer visible, peels off or is

otherwise unclear, apply a new warning label.

For the warning label, refer to your Hitachi Authorized

Service Center.

26. When working, if local rules or regulations apply,

comply with the same.

27. Recommendation for the use of a residual current

device with a tripping current of 30 mA or less

28. Statement to position the cord of so that it will not be

caught on branches and the like, during cutting

29. Recommendation that the fi rst-time user should, as

a minimum practice, cutting logs on a saw-horse or

cradle

DESCRIPTION OF NUMBERED ITEMS (Fig. 2 - Fig. 38)

1

Kickback zone

@

Blade direction

e

Oil sight glass

f

1/5 of diameter of fi le

2

Chain brake

#

Chain tensioner hole

r

Oil pump adjuster

g

Depth gage jointer

3

Free

$

Chain tensioner boss

t

Lock-off button

h

Flat fi le

4

Lock

%

Increase the tension

y

Switch

j

Protruding depth gage

head

5

Knob

^

Decrease the tension

u

Plug clip

k

Round off

6

Tension dial

&

Drive link

i

Plug

l

Brake band chamber

7

Side cover

*

Fasten

o

Extension cord

;

Chain oil spout

8

Guide bar

(

Pull

p

Spiked bumper

z

Groove

9

Saw chain

)

Actuation

a

Front handle

x

Oil hole

0

Guide bar tip

q

Release

s

Rear handle

c

Chain catcher

!

Sprocket

w

Chain oil

d

Round fi le

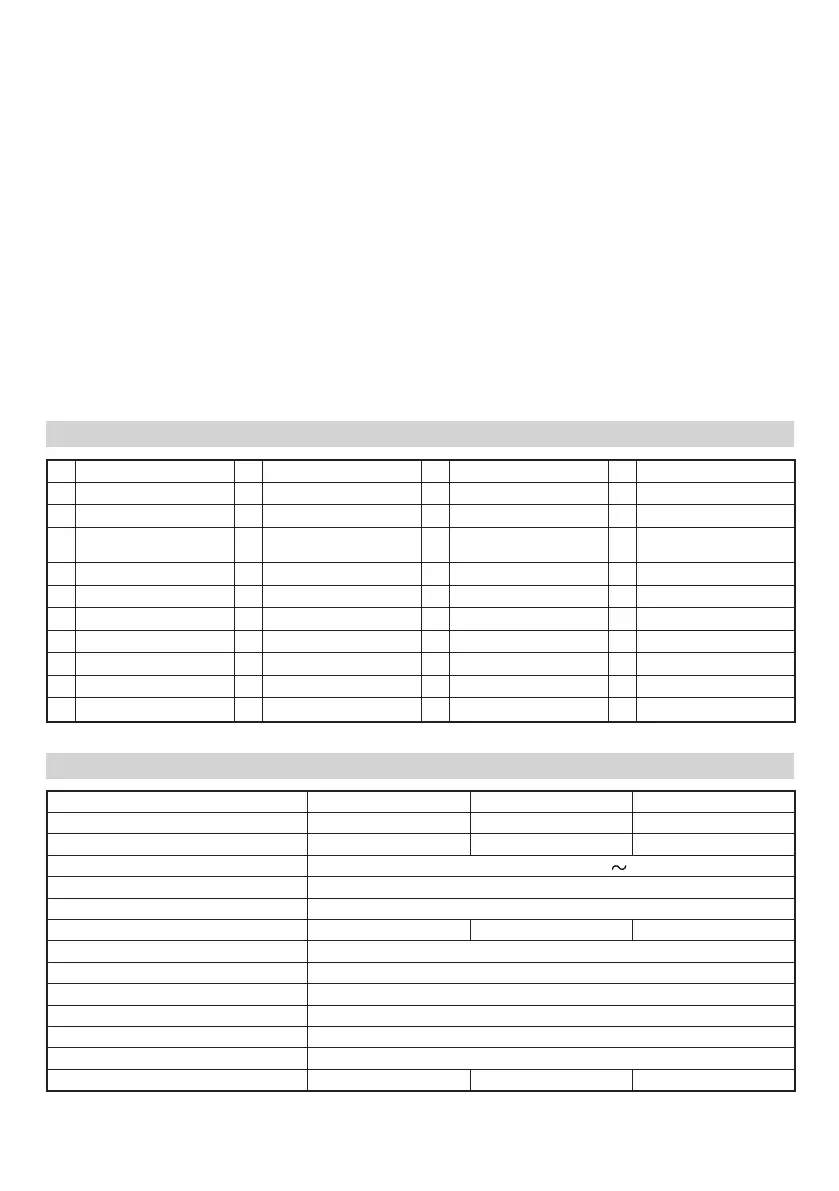

SPECIFICATIONS

Model CS30SB CS35SB CS40SB

Guide bar length (Max. cutting length) 300 mm 350 mm 400 mm

Guide bar Type P012-50CR P014-50CR P016-50CR

Voltage (by areas)*

1

(220 V, 230 V, 240 V)

Power Input*

1

1900 W

No-load chain speed 14.5 m/s

Type of chain 91PX-45 (Oregon) 91PX-52 (Oregon) 91PX-57 (Oregon)

Chain pitch / Gauge 9.53 mm (3/8") / 1.27 mm (0.05")

Sprocket Number of teeth: 6

Oil pump Automatic

Chain oil tank capacity 200 ml

Overload protection Electrical

Chain brake Manually actuated

Weight*

2

4.7 kg 4.8 kg 4.9 kg

*1 Be sure to check the nameplate on product as it is subject to change by areas.

*2 Weight: According to EPTA-Procedure 01/2003

0000BookCS30SB.indb80000BookCS30SB.indb8 2015/03/1317:18:442015/03/1317:18:44

Loading...

Loading...