23

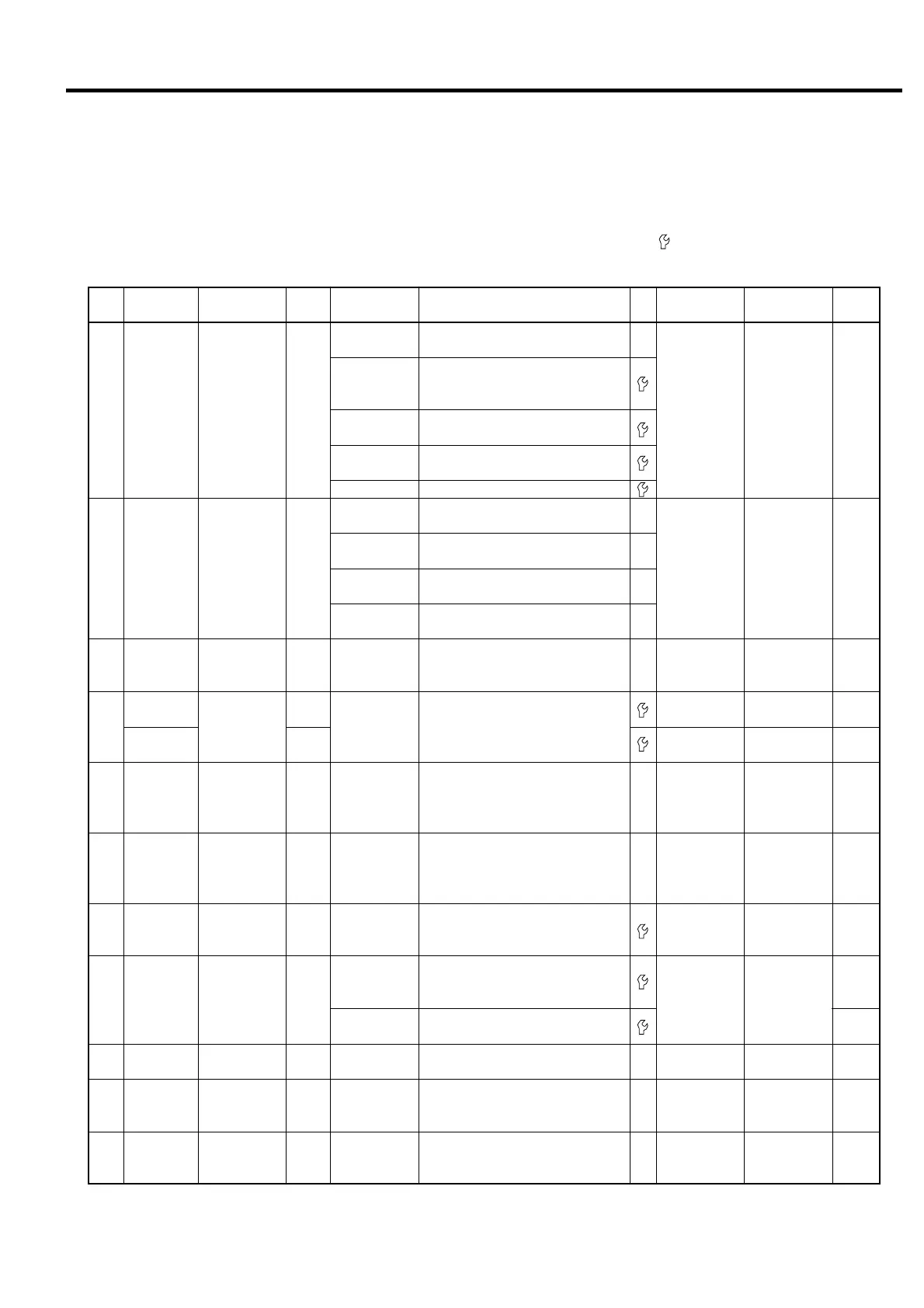

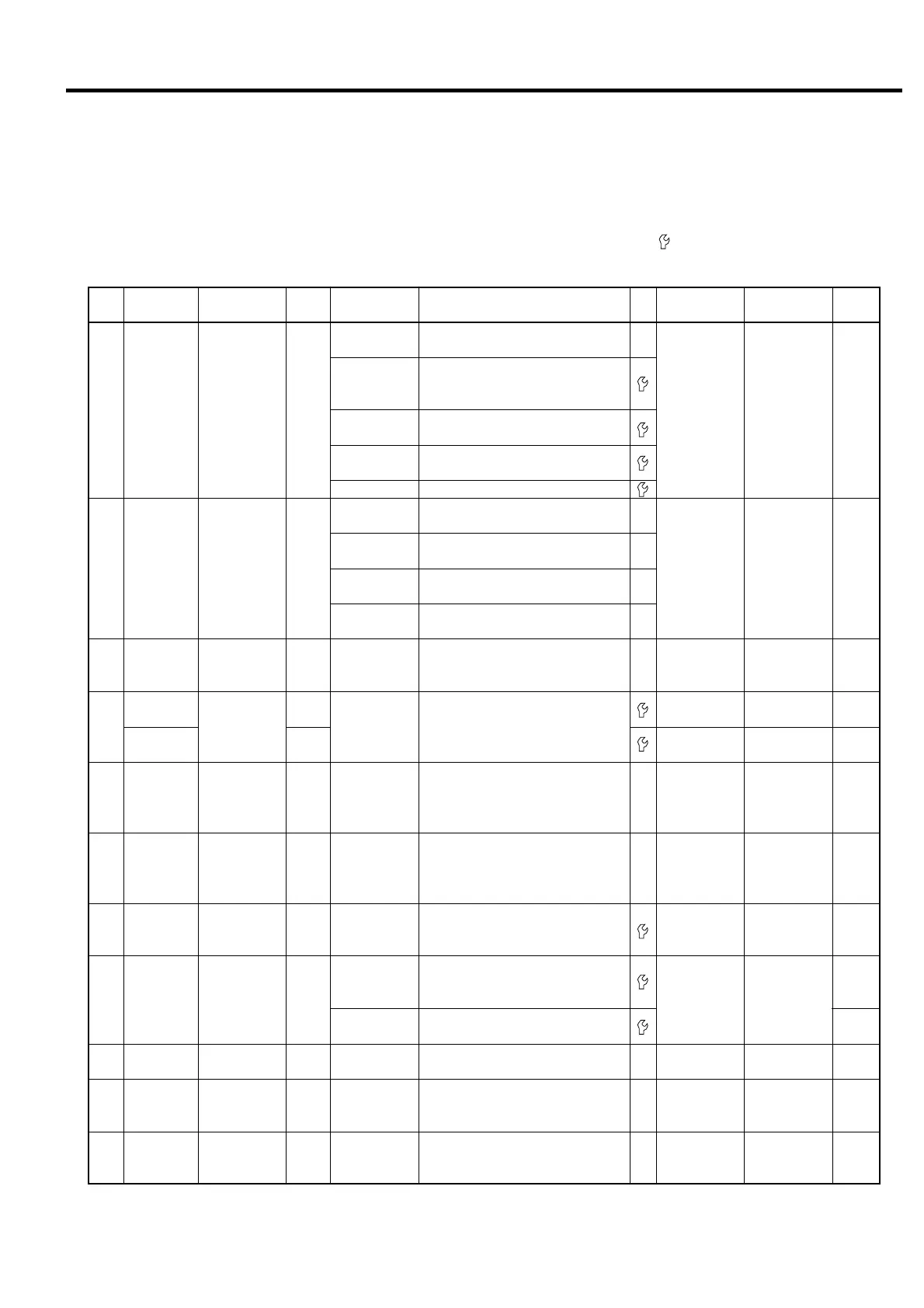

5. TROUBLESHOOTING [SHUTDOWN/ALARM Indications on the Instrument Panel]

5.3 SHUTDOWN/ALARM Indications on the Instrument Panel

When a problem occurs, the SHUTDOWN, ALARM or AUTO START light flashes and the digital monitor displays

a corresponding ALARM or SHUTDOWN (as ‘A/S’ below) code. If this is the case, refer to the following table to

identify the cause. If you cannot identify the cause, or for the problem with a mark in the table, contact a

Hitachi distributor.

A/S

Code

Yes

Yes

No

Yes

No

Yes

Yes

Yes

Yes

Yes

Yes

Yes

E-17

E-18

E-23

E-19

E-01

E-02

E-11

E-12

E-14

E-16

E-51

SHUTDOWN:

On (flashing)

SHUTDOWN:

On (flashing)

ALARM:

On (flashing)

SHUTDOWN:

On (flashing)

ALARM:

On (flashing)

SHUTDOWN:

On (flashing)

SHUTDOWN:

On (flashing)

SHUTDOWN:

On (flashing)

SHUTDOWN:

On (flashing)

SHUTDOWN:

On (flashing)

SHUTDOWN:

On (flashing)

SHUTDOWN:

On (flashing)

Overloading

High discharge

temperature 1 (*)

High discharge

temperature 1 (*)

Failed air dryer

Reversal phase

connection

Phase-lacking

connection

High discharge

temperature 2 (*)

Abnormally

high discharge

pressure

Option

Answer error of

contactor 42

Answer error of

contactor 52

Failure of power

supply

High discharge

pressure

High discharge

pressure

Failure of main motor

and/or cooling fan motor

Failure of air end

High ambient

temperature

Low oil level

Dirty or clogged

oil cooler

Dirty or clogged

oil filter

Same as

the E-18 above

Tripping of an air

dryer’s protective

device during

operation

Power connected

in a reversal phase

Power connected

with a lack of

phase

Failure of oil

separator

element

Failure of oil

separator

element

Failure of

contactor 52

Failure of

contactor 42

(42 answer error)

Failure of

contactor 52

(52 answer error)

Check the power supply for a voltage drop

and imbalance. Correct it if required.

Check and correct the capacity control settings and/

or readjust the modulator valve, if the discharge pres-

sure is higher than the specification pressure.

Check the oil separator element. Replace

it if it is clogged.

Check the motor for insulation resistance

etc.

Check the air end.

Ventilate the room to reduce the ambient

temperature to 40°C.

Add oil. (Disconnect the power and make sure that the

discharge pressure gauge reads 0 MPa in advance.)

Clean the cooling fins. See page 51.

Replace the oil filter. See page 49.

Same as the E-18 above

See page 25.

Disconnect the power and change 2 of

the 3 power cord wires.

Check the power supply. Tightly reconnect

the power cord wires.

Replace the oil separator element and the

oil.

Check the oil separator element. Replace

if required.

Disconnect the power and tightly reconnect

the 52 wires.

Disconnect the power and check the 42.

Tightly reconnect the 42 wires. Replace the

42 if necessary.

Disconnect the power and check the 52.

Tightly reconnect the 52 wires. Replace the

52 if necessary.

Press the reset

button of the

thermal

overload relay.

Press the

RESET button.

Automatically

reset.

Press the

RESET button.

Press the

RESET button.

Disconnect and

reconnect the

power.

Disconnect and

reconnect the

power.

Press the

RESET button.

Press the

RESET button.

Press the

RESET button.

Press the

RESET button.

Tripping of

thermal

overload relay

Discharge

temperature 1

over 110°C

Discharge

temperature 1

over 105°C

DIP switch SW1

No.2 set to OFF

DIP switch SW1

No.2 set to ON

Detected for 3

seconds after

connecting the

power

Detected for 3

seconds after

connecting the

power

Discharge

temperature 2

over 110°C

Detected during

delta operation

Detected during

delta operation

Detected during

star operation

Light:

Action

Category of

Problem

A

Shutdown

Causes What Actions to Take

Mark

What and How

to Detect

How to

Reset

A/S

History

17

18

23

19

19

01

02

11

12

12

14

16

51

Loading...

Loading...