28

TH1 : Thermistor (discharge temp. 1)

TH2 : Thermistor (discharge temp. 2)

PS(1): A pressure sensor (for capacity control)

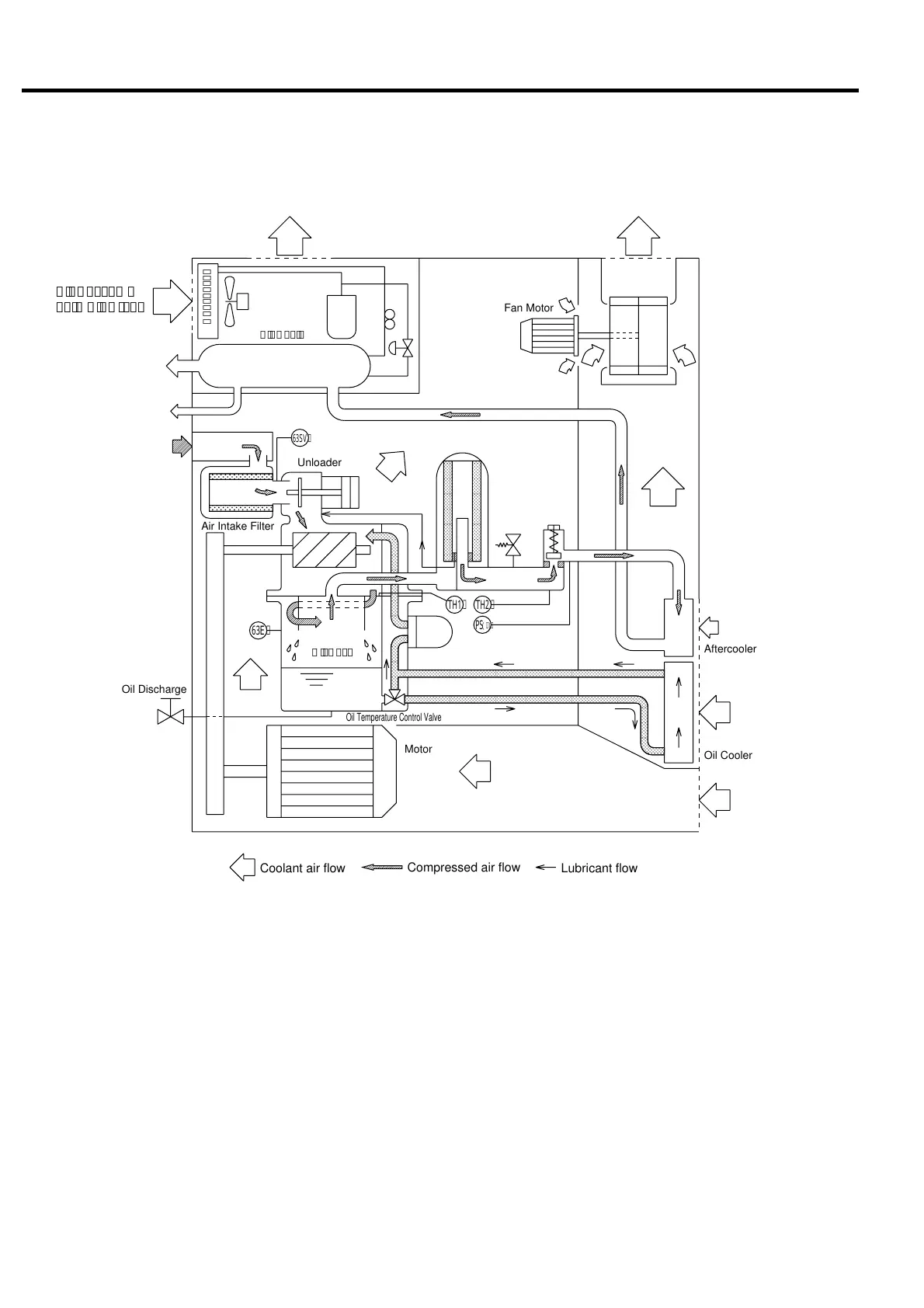

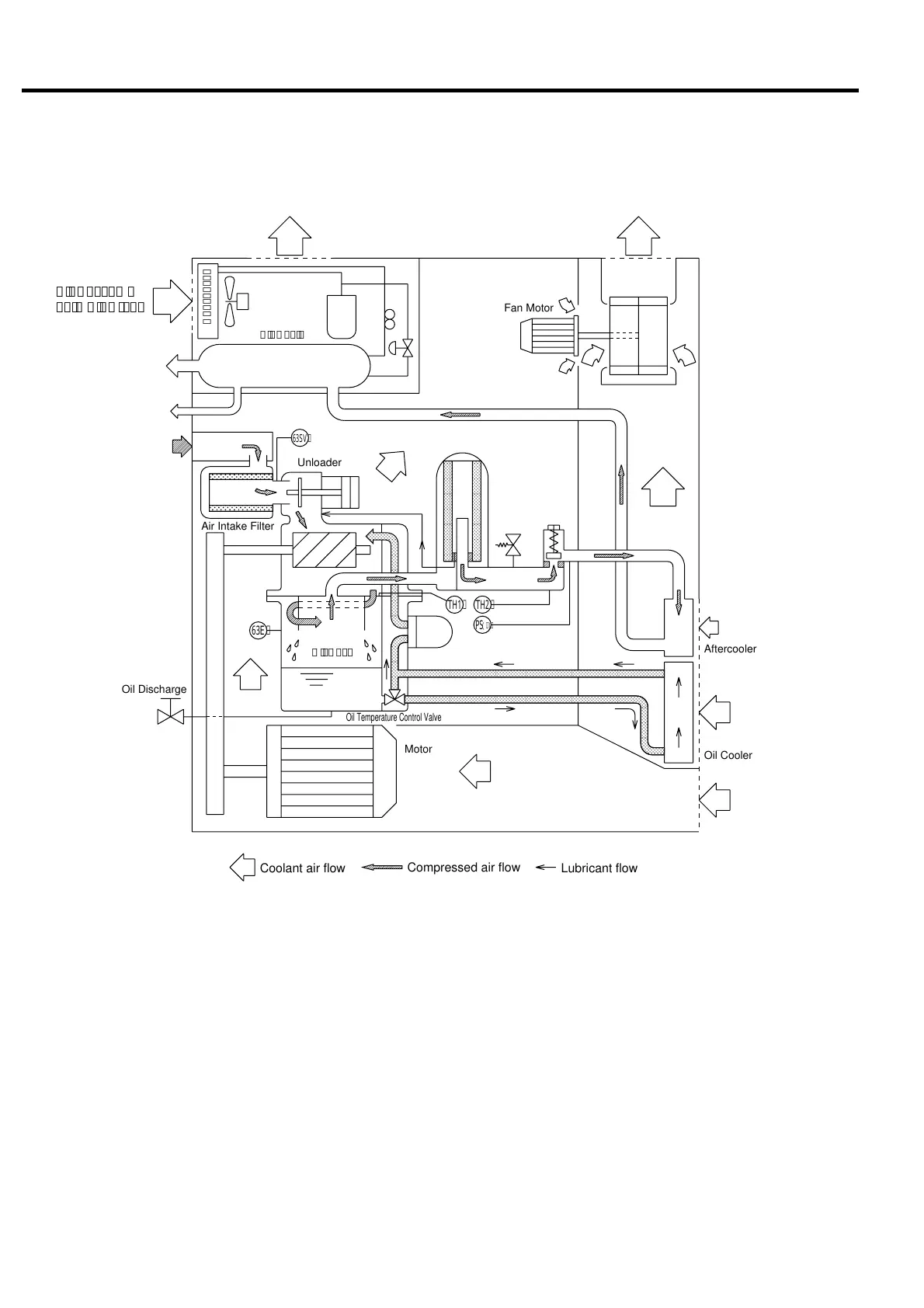

6. SYSTEM OF EACH COMPONENT

6.1 Compressed Air/Lubricant System

6.1.1 Compressed air flow

The air under atmospheric pressure is taken in

the unit through Air Intake Filter and is com-

pressed by a compressor to the specified pressure.

This Compressed Air flows in the Oil Case to-

gether with Lubricant, and by which Compressed

Air and Lubricant are separated. Segregated

Compressed Air is cooled in the Aftercooler and

then discharged out.

6.1.2 Lubricant flow

The Lubricant circulates in the unit by means of

pressure difference between the pressure in the

Oil Case and the one in the suction side of the

Compressor. The mixture of Compressed Air and

Heat Exchanged Lubricant are separated in the

Oil Separator into the Compressed Air and the

Lubricant. Segregated Lubricant is cooled in the

Oil Cooler afterwards and returns to the suction

side of Compressor, then it makes Heat Exchange

with another Compressed Air again.

63E : Pressure switch

63SV : Pressure differential sensor of air intake filter

;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;;

Lubricant flow

Compressed air flow

Coolant air flow

TH1

PS

(1)

TH2

63SV

63E

Oil Discharge

AirSucked

ontoAirDryer

Fan Motor

Motor

OilCase

Unloader

Oil Temperature Control Valve

Air Intake Filter

Oil Cooler

Aftercooler

Condenser

AirCooler

CoolingFan

Refrigerant

Compressor

Cooling Fan

Oil Separator

Oil Filter

Relief

Valve

AirExhaustedfromAirDryer AirExhaustedfromAirCompressor

AirSuckedonto

Aftercooler

AirSuckedonto

OilCooler

AirSuckedonto

Motor

CompressedAir

Discharged

Condensate

Drained

AirSuckedinto

AirEnd

Minimum

Pressure/

Check Valve

Compressor

Loading...

Loading...