60-2080—8 8

V48A,F,J; V88A,J

INSTALLATION • OPERATION

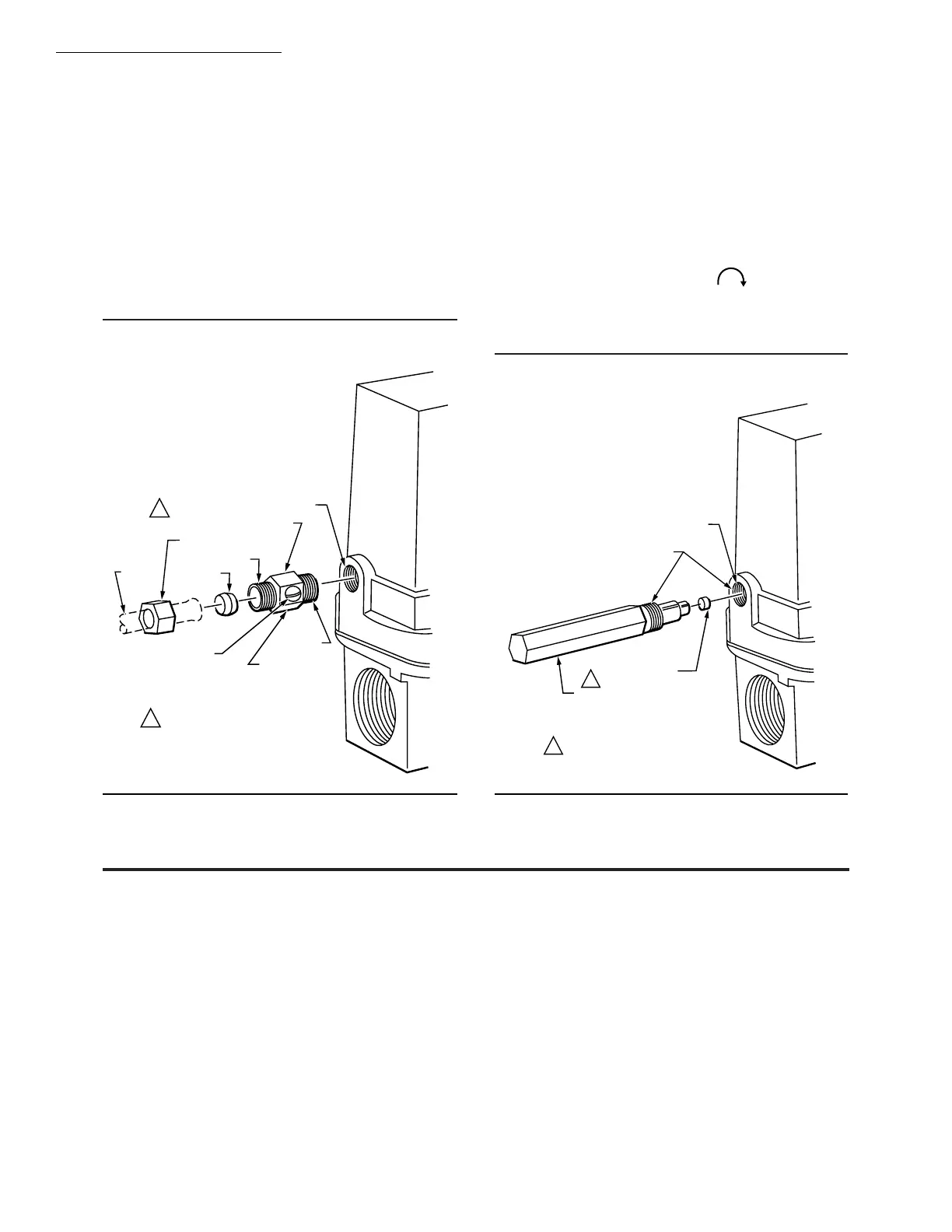

INSTALLATION OF AN OPTIONAL ADJUSTABLE

BLEED VALVE (FIG. 8)

NOTE: This device is not available for valves with BSP.PI

threads.

Screw the 126590 Adjustable Bleed Valve into the

tapping marked BLEED. Be sure to screw the end with the

1/8-NPT threads into the BLEED tapping. Complete the

bleed line connection. Then alternately energize and de-

energize the valve actuator, and adjust the screw on the

bleed valve for the desired valve opening time.

Fig. 8—Installing optional 126590 adjustable

bleed valve.

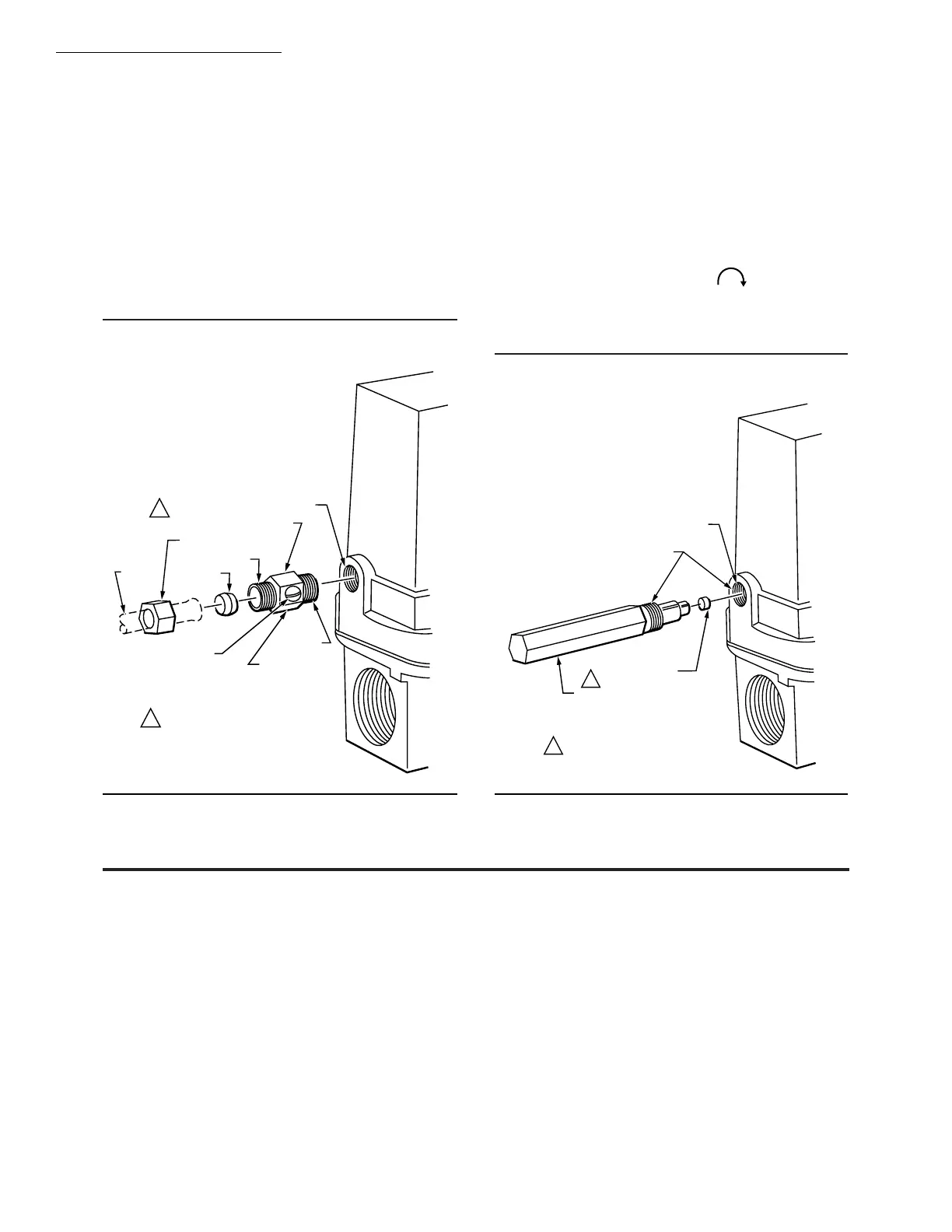

INSTALLATION OF AN OPTIONAL BLEED

ORIFICE (FIG. 9)

NOTE: The orifice tool cannot be used on valves with

BSP.PI threads.

Press the selected bleed orifice (see Table 2) over the

slotted end of the 126070 Orifice Tool. With the tool, insert

the orifice into the bleed port until the tool, threads mate

with the threads in the bleed port. Finger-thread the tool

into the bleed port (turn clockwise ) as far as pos-

sible; then use pliers to seat the orifice. Seating occurs

when the threading stops. Withdraw the tool and complete

the connection of the bleed tubing.

Fig. 9—Installing optional bleed orifice.

Operation

OPERATION OF THE V48 AND V88 (FIG. 10)

When the controller is not calling for heat, the coil is de-

energized. The plunger in the 3-way actuator is in the

DOWN position so the bleed port is closed and the supply

port is open. Gas flows into the top part of the valve. The

gas pressure on top of the diaphragm, the weight, and the

spring hold the valve closed.

On a call for heat, the controller contacts close and the

coil is energized. This pulls the plunger to the UP position,

opening the bleed port and closing the supply port. The gas

in the top of the valve flows out through the bleed port. This

reduces the pressure on top of the diaphragm, allowing the

gas pressure below to lift the diaphragm and open the

valve.

When all the gas has bled off the top of the diaphragm,

the valve is fully open, permitting gas flow to the main

burner.

After the controller is satisfied, the procedure is reversed.

The controller contacts open so the coil is de-energized. The

plunger is released, moving to the DOWN position. This

closes the bleed port and opens the supply port so gas flows

again into the top port of the valve. As the gas pressure on

top of the diaphragm increases, the diaphragm begins to

close. When the pressures on both sides of the diaphragm

are balanced, the valve will be closed. The weight and

spring help to close the valve. If the gas supply fails and

there is no pressure below the diaphragm, the weight and

spring will close the valve.

BLEED TAPPING

126590 ADJUSTABLE BLEED VALVE

SLEEVE

COMPRESSION NUT

1/4 INCH

TUBING

7/16-24 UNS

ADJUSTING SCREW

7/16 INCH HEX

1/8-27 NPT

THIS DEVICE WILL NOT FIT VALVES

WITH BSP.PL THREADS.

1

1

M7290

BLEED PORT

1/8-27 NPT

THIS TOOL WILL NOT FIT VALVES

WITH BSP.PL THREADS.

1

1

M7298

ORIFICE TOOL

BLEED ORIFICE

(SELECTED)

Loading...

Loading...