13

Cleanness

Dust buildup on the chassis may result in electrostatic adsorption, which causes poor contact of metal

components and contact points, especially when indoor relative humidity is low. In the worst case,

electrostatic adsorption can cause communication failure.

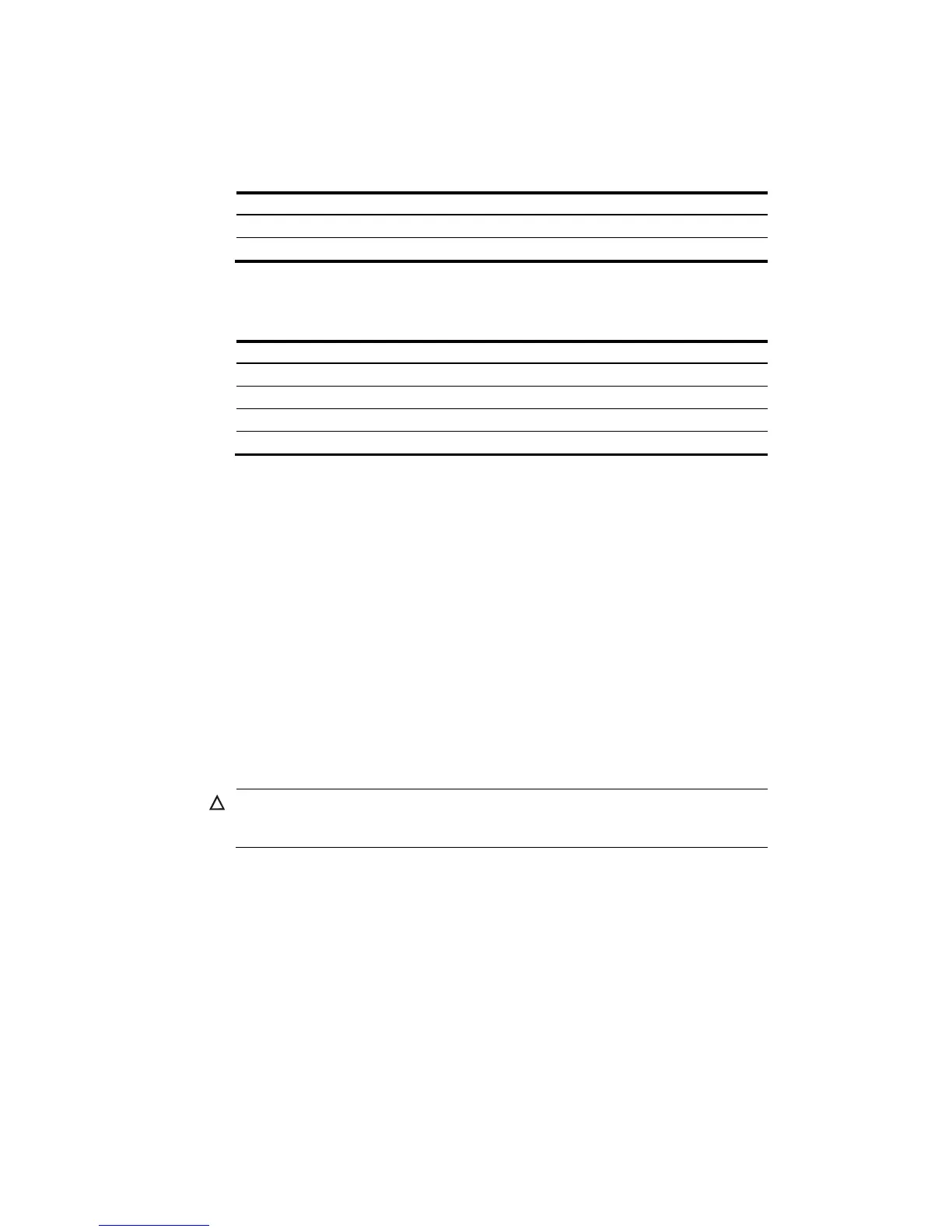

Table 12 Dust concentration limit in the equipment room

Substance Concentration limit (

Dust

≤ 3 x 10

4

(no visible dust on the tabletop over three days)

Note: The dust diameter is greater than or equal to 5 μm.

The equipment room must also meet strict limits on salts, acids, and sulfides to eliminate corrosion and

premature aging of components, as shown in Table 13.

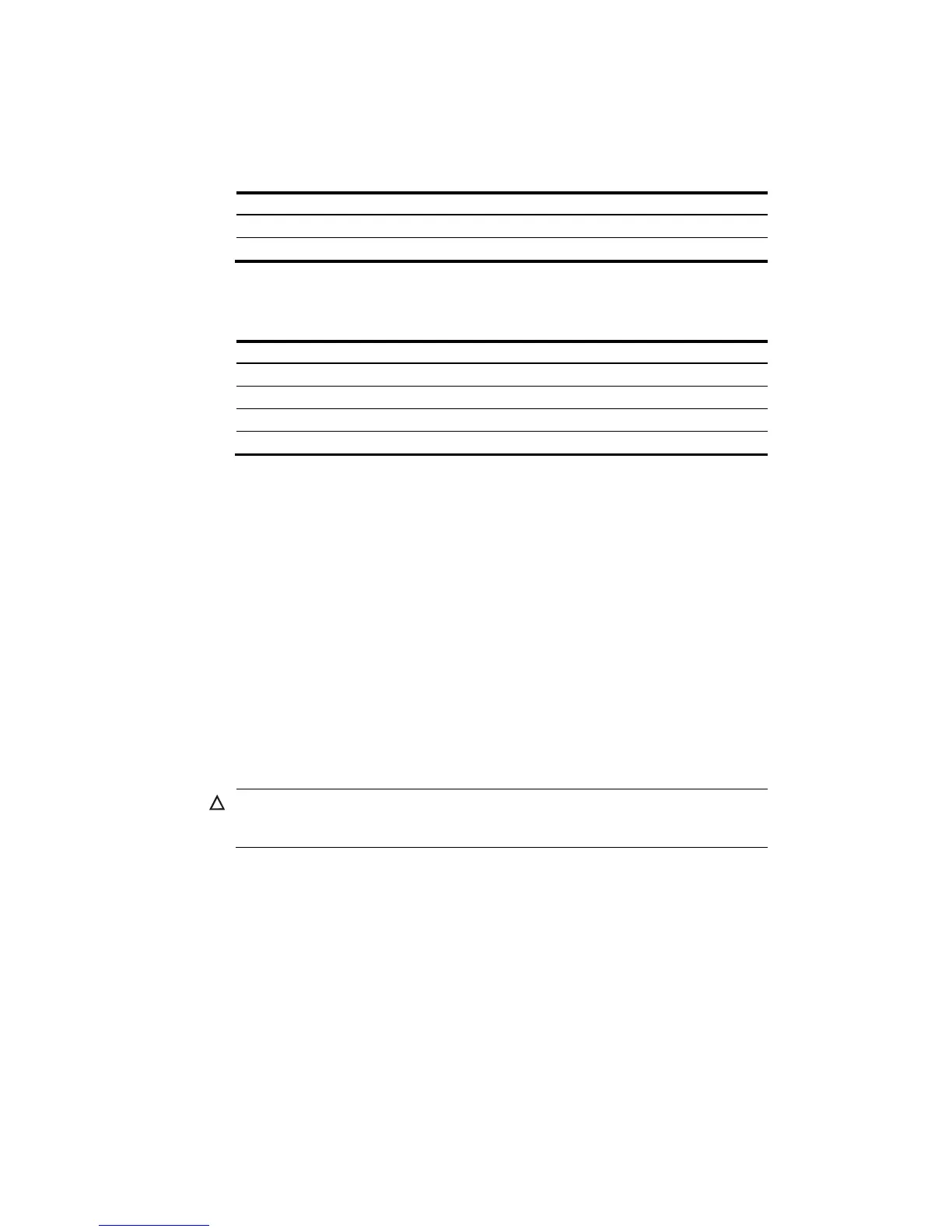

Table 13 Harmful gas limits in the equipment room

Gas Maximum concentration (m

/m

3

)

SO

2

0.2

H

2

S 0.006

NH

3

0.05

Cl

2

0.01

EMI

All electromagnetic interference (EMI) sources, from outside or inside of the switch and application

system, adversely affect the switch in a conduction pattern of capacitance coupling, inductance coupling,

electromagnetic wave radiation, or common impedance (including the grounding system) coupling. To

prevent EMI, take the following actions:

As the AC power system is a TN system, use a single-phase three-wire power receptacle with a

protection earth (PE) to filter interference from the power grid.

Keep the switch far away from radio transmitting stations, radar stations, and high-frequency

devices.

Use electromagnetic shielding, for example, shielded interface cables, when necessary.

Route interface cables only indoors to prevent signal ports from getting damaged by over-voltage

or over-current caused by lightning strikes.

Laser safety

The V1910 Switch Series is a line of class 1 laser devices.

CAUTION:

hen an SFP module on a V1910 switch is operating, do not stare into the optical port because the laser

light emitted from the optical fiber may hurt your eyes.

Loading...

Loading...