Cut charts

16 811270 Instruction Manual MAXPRO200

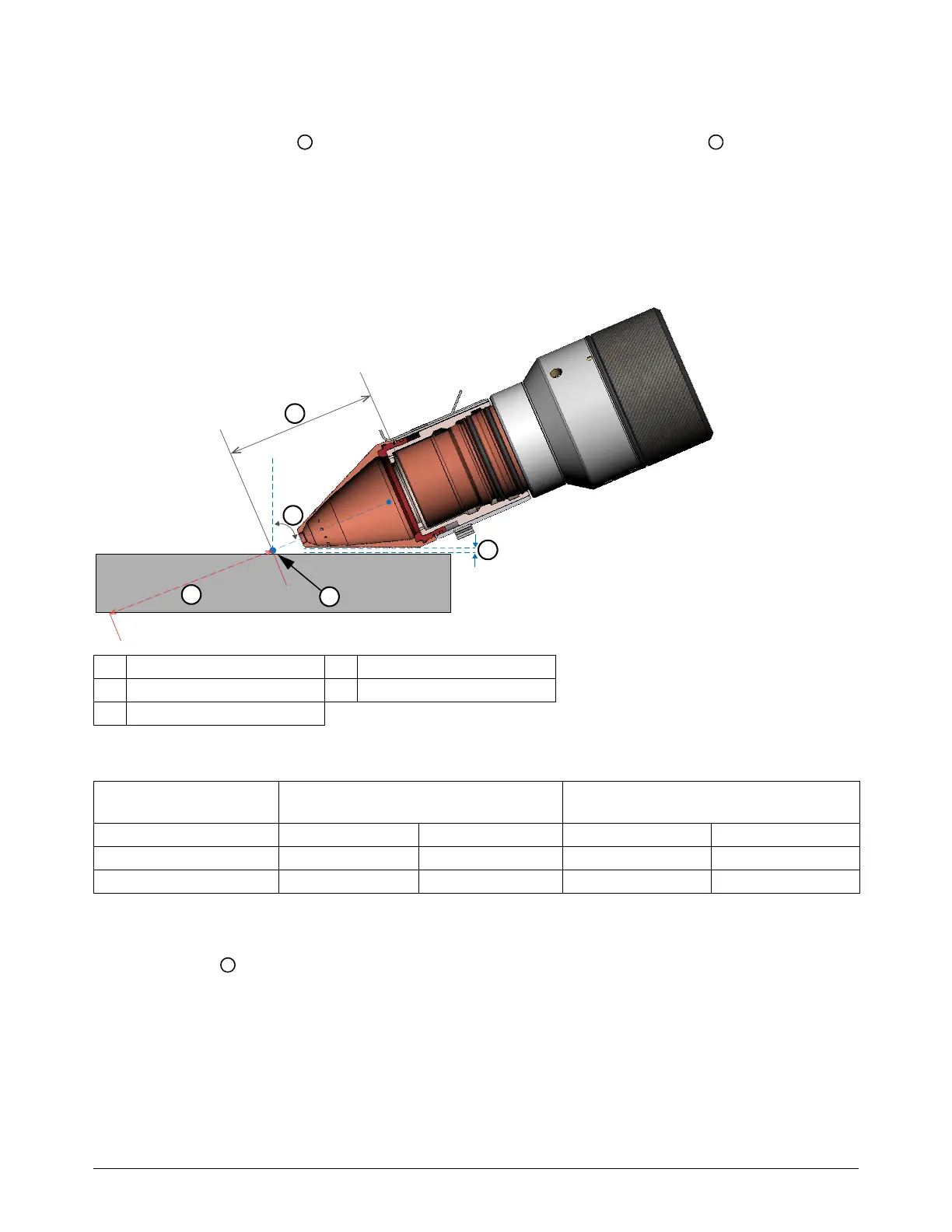

Recommended torch-pivot lengths

The bevel-pivot point has an effect on the recommended torch-pivot length . The bevel-pivot

point is the intersection of the torch axis and the top of the workpiece when the torch is at its

maximum angle and minimum clearance.

The use of extreme bevel consumables increases the recommended torch-pivot length by more than

100%. Refer to Figure 1 and Table 1.

Figure 1

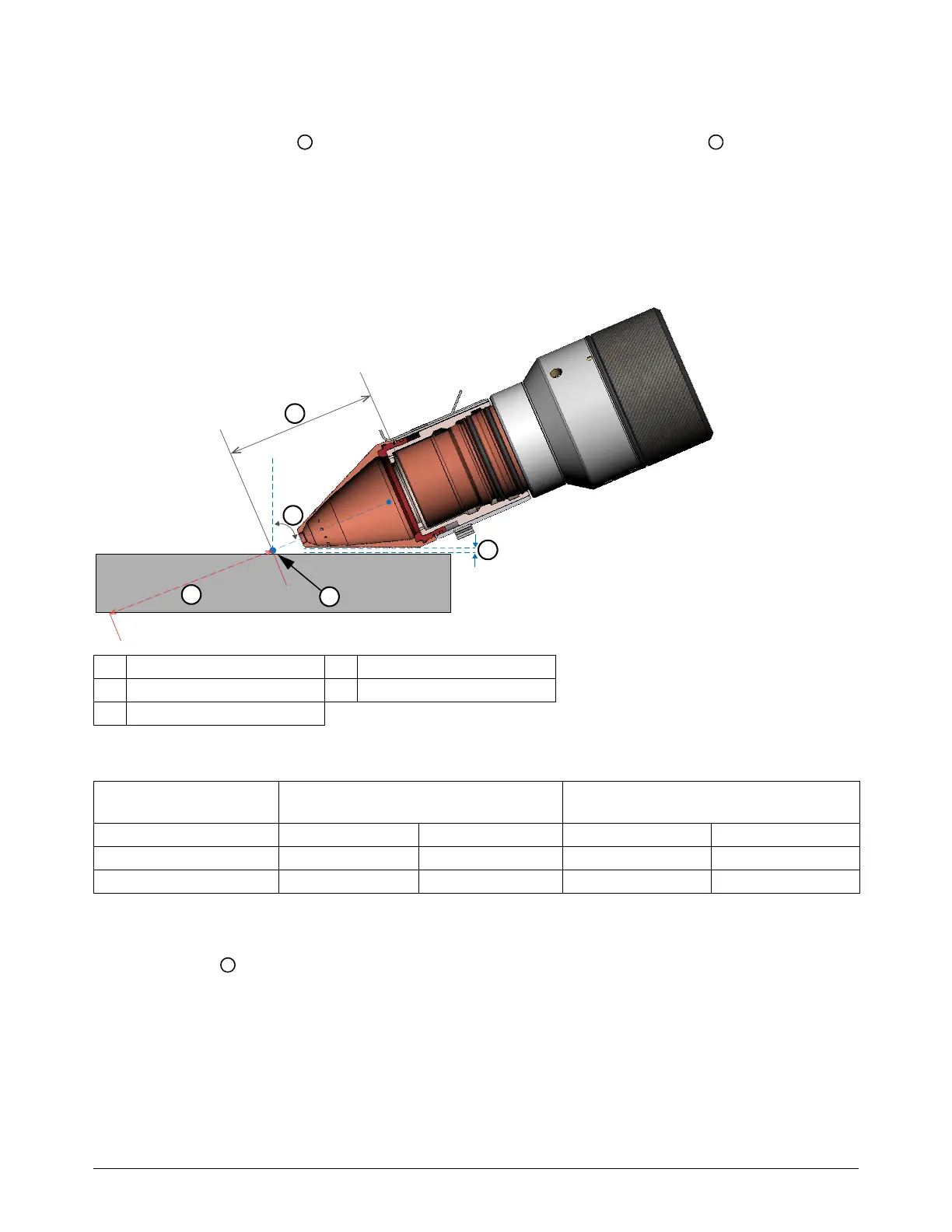

Table 1 – Recommended torch-pivot lengths by product type

Clearance

Clearance is the minimum distance between the torch and the top of the workpiece. A higher

clearance can decrease the chance of torch collisions with the workpiece. But, it can also cause the

following conditions:

Increased cut heights that give bad edge quality and make higher-angle compensations

necessary

Increased voltages that can have a bad effect on the duty cycle of the plasma power supply

1 Torch-pivot length 4 Clearance

2 Maximum tilt angle 5 Bevel-pivot point

3 Effective thickness

MAXPRO200 standard mechanized

consumables

MAXPRO200 extreme bevel

consumables

Torch-pivot length 30mm (1.18in.) 31mm (1.24in.) 62mm (2.44in.) 65mm (2.55 in.)

Maximum torch angle 45 degrees 45 degrees 66.5 degrees 66.5 degrees

Clearance 2 mm (0.08 in.) 3 mm (0.125 in.) 2 mm (0.08 in.) 3 mm (0.125 in.)

In this example, the torch-pivot length shows the

extreme-bevel consumables at 66.5 degrees and

at a clearance of 2 mm (0.080 in.).

1

2

3

4

5

Loading...

Loading...