Cut charts

MAXPRO200 Instruction Manual 811270 17

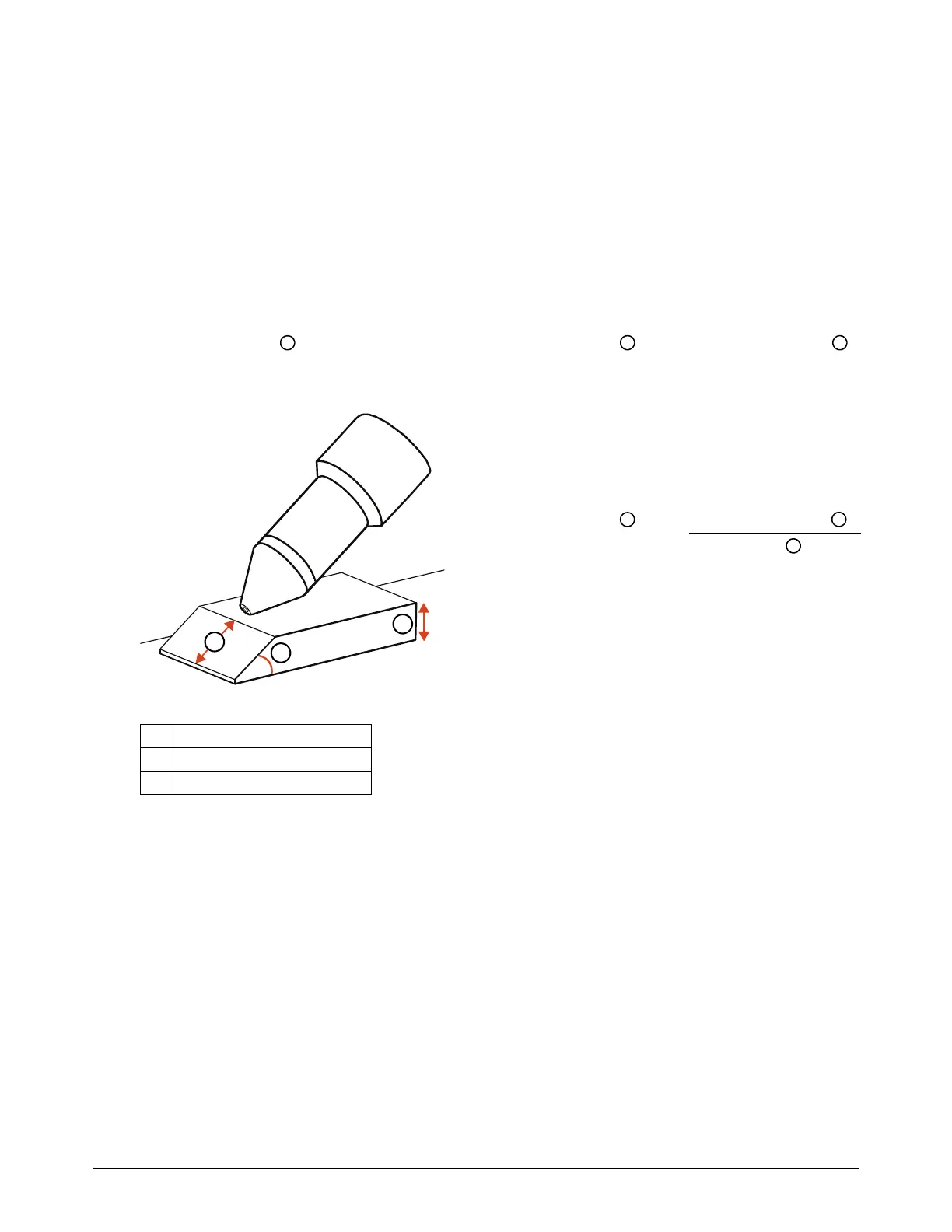

Maximum torch angle

The maximum torch angle with extreme bevel consumables is 66.5 degrees at a clearance of 2 mm

(0.080 in). Using a maximum torch angle during bevel cutting increases the effective thickness of

the workpiece being cut. For example, bevel cutting a 12 mm (.50 inch) workpiece at a 60-degree

angle is like cutting a 25 mm (1 inch) workpiece at a 90-degree angle. Refer to Effective thickness.

Hypertherm recommends using the default torch-clearance settings to start cutting. Adjust

clearance settings only when necessary.

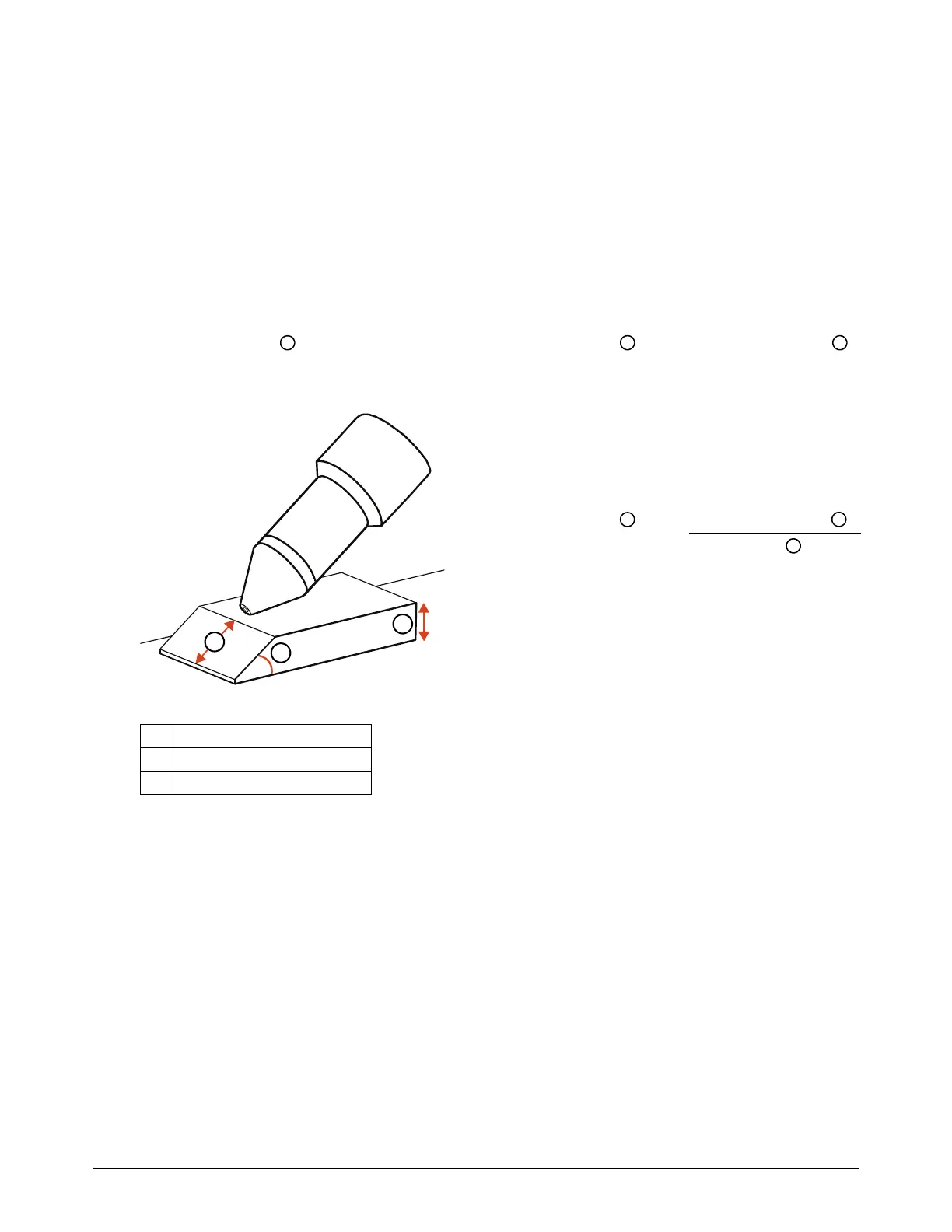

Effective thickness

Effective thickness is directly related to the workpiece thicness and the angle of the torch .

When cutting at an angle, the thickness that the torch has to cut is increased.

Effective thickness

=

Workpiece thickness

sin(a)

1 Effective thickness

2 Angle of the torch – sin(a)

3 Workpiece thickness

Loading...

Loading...