Cut charts

18 811270 Instruction Manual MAXPRO200

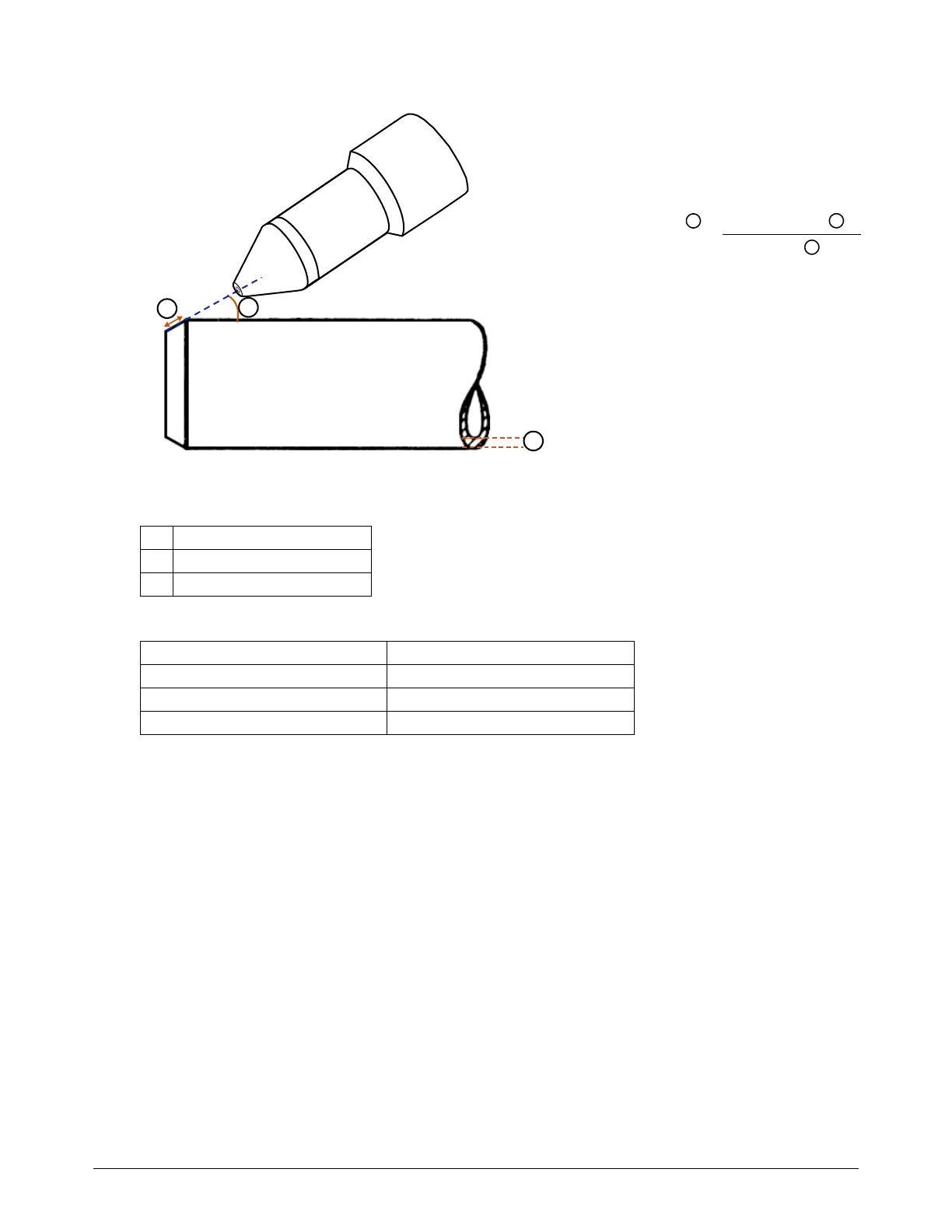

The table below shows how effective thickness changes with different torch angles.

You can calculate the effective thickness for any thickness and torch-angle combination with the

following formula:

Effective thickness = Workpiece thickness / sin(a)

Hypertherm recommends that you use the thickness settings in the cut chart that are most similar to

the effective thickness that you want to cut. After cutting starts, adjust thickness settings only as

necessary.

Effective thickness = Wall thickness

sin(a)

* For pipe cutting, substitute “workpiece thickness” with “wall thickness” to calculate the effective thickness.

1 Effective thickness

2 Angle of the torch – sin(a)

3 Wall thickness

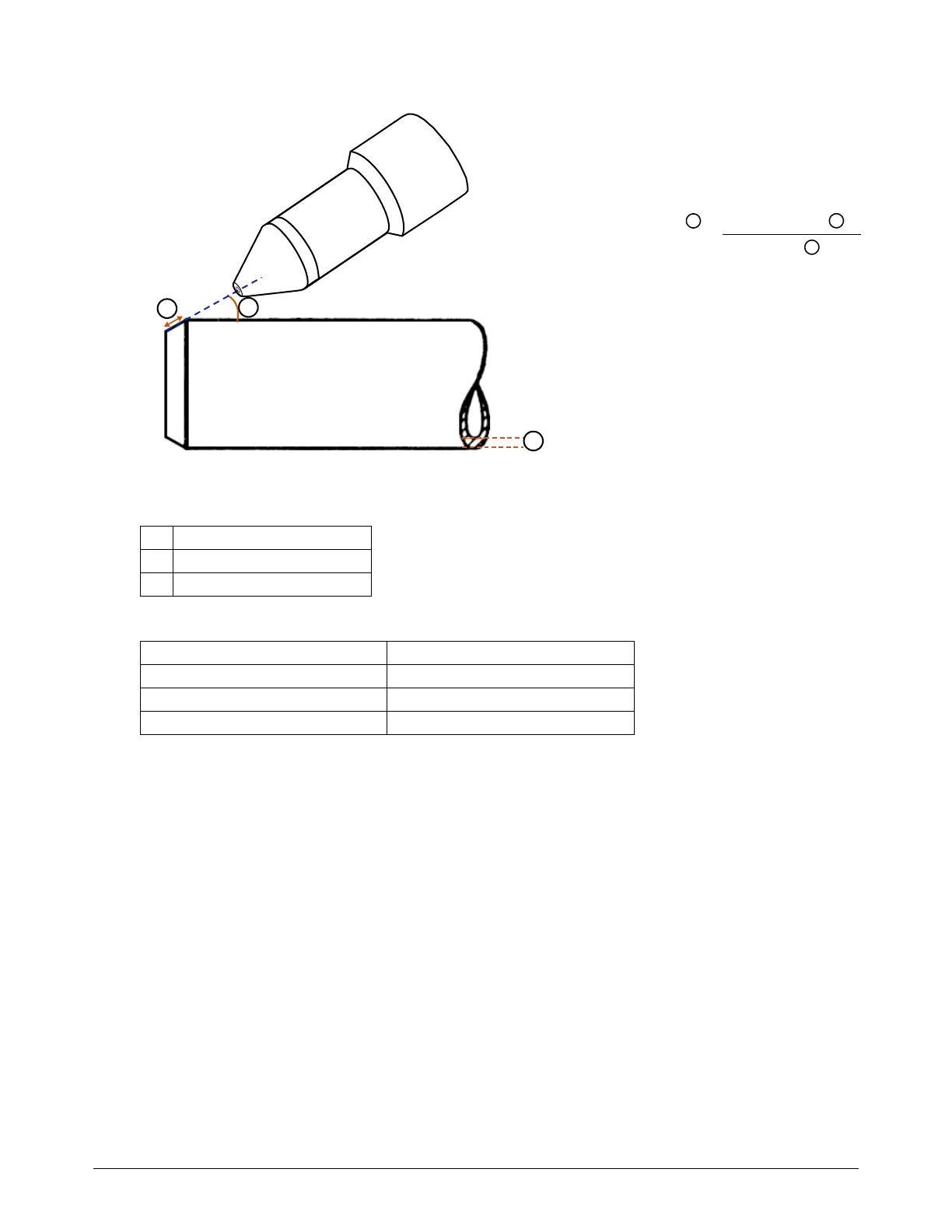

Effective thickness Torch angle

12 mm (.50 inch) 90 degrees

17 mm (.71 inch) 45 degrees

25.4mm (1.00inch) 60 degrees

Loading...

Loading...