MAINTENANCE

powermax1650 Service Manual

3-11

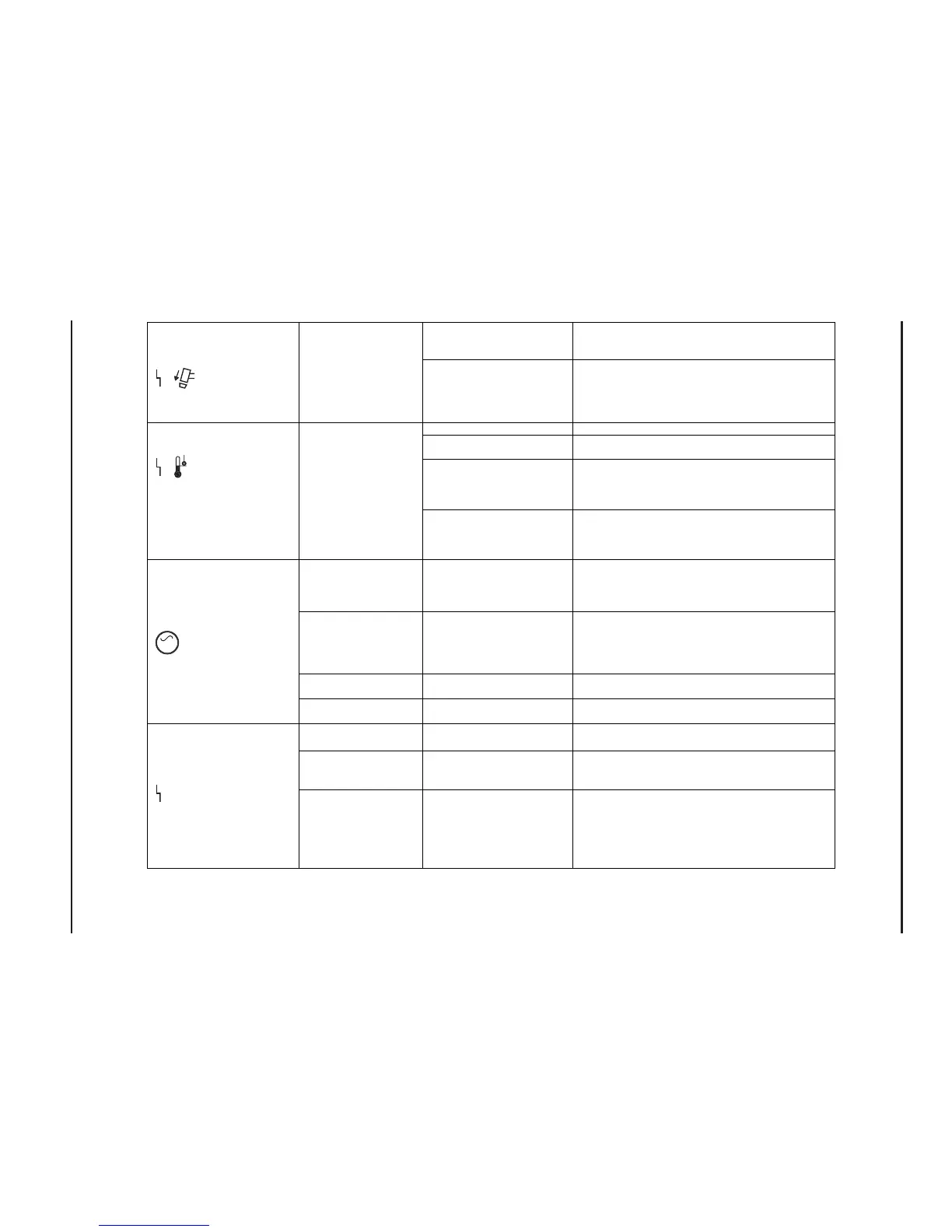

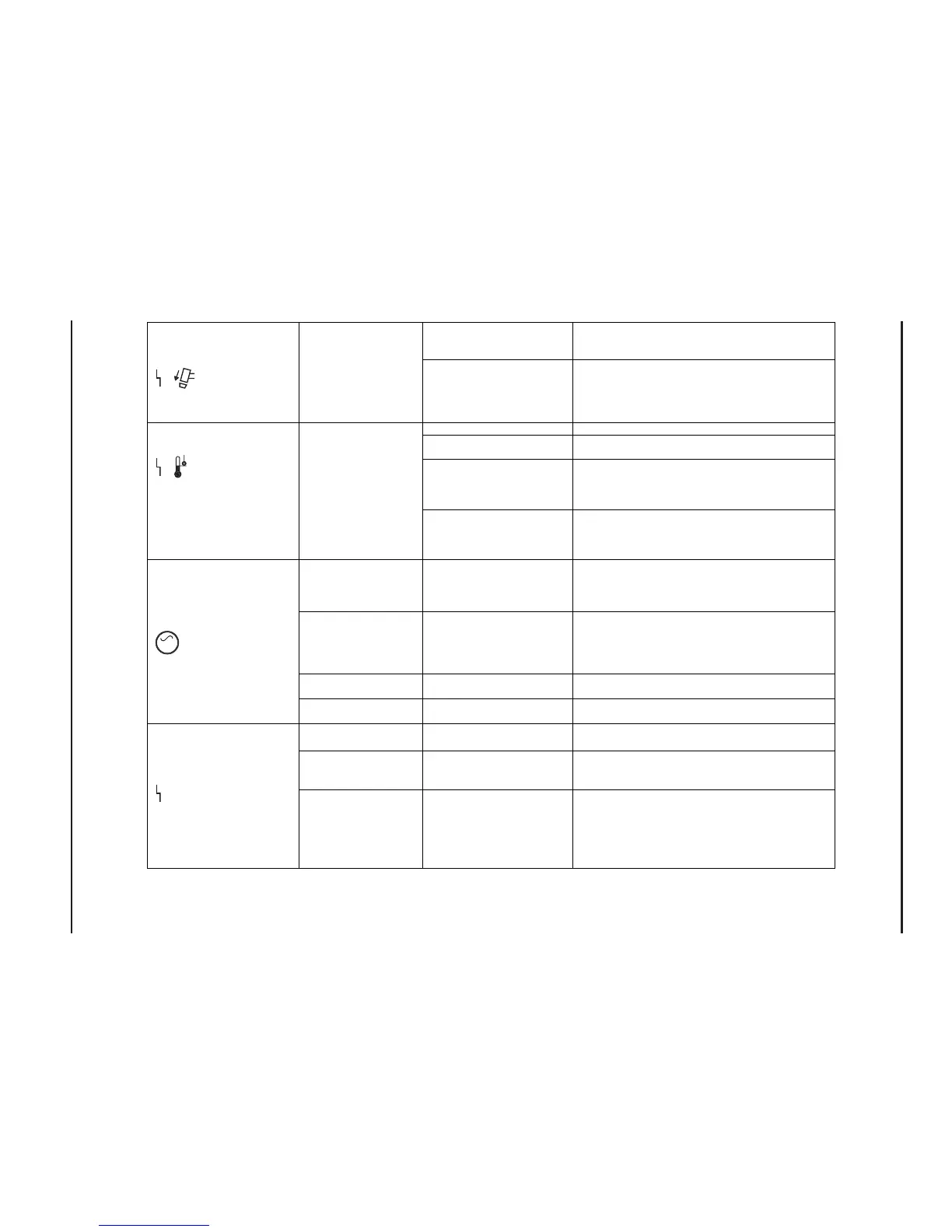

0

Consumables not installed,

installed improperly, or

dama

ed

Refer to consumable diagram for proper installation.

Try new consumables.

Damage to safety circuit Remove torch. Check torch end of connector. Install

consumables and check continuity on J18, pins 11 and

12 orange and blue wires. If open circuit, inspect torch

and lead assembly. Replace lead or cap switch as

necessar

cle Allow unit to cool. Sta

cle limits in manual.

Fan not operating or

improperl

Disconnect J2 and jump pins 1 and 2. Fan should

operate.

Defective heatsink temperature

switch TP1 (check when

system is cool, at least 15 min

after use

Remove J2 from power board (PCB2). Check

temperature PCB (PCB4) by checking resistance on

pins 1 and 2. If resistance is not between 3k-5k ohms,

replace temperature sensor PCB

.

Defective power transformer

(T2) temperature sensor TS2

(check when system is cool, at

least 60 min after use

Check transformer sensor (T2) by checking resistance

on J21 pins 1 and 2 on wires. If greater than 15 k

ohms, replace power transformer.

Start signal not being

received by power

supply. Start LED off on

control board (PCB3).

Damage to torch and lead

assembly.

Remove torch. Check J18 pins 10 and 12 violet and

orange wires for continuity when torch trigger is

depressed. If open circuit, inspect torch and lead

assembly.

Solenoid valve not

working

Valve stuck or no voltage to

valve

Check voltage at valve. Remove connector J21 from

valve, turn current adjust knob to test flow and check

for 24 VDC at connector J21 pins 1 and 3. If no

voltage, replace power board. If voltage, clear air lines

or replace valve.

Damaged torch or lead

assembl

Torch plunger stuck open or

broken torch leads

Verify fault: control board (PCB3) TSO LED illuminated.

Inspect torch and lead assembl

Defective control board Replace board.

Worn or bad

consumables

Overuse or improperly installed

consumables

Replace consumables.

Insufficient air flow Improper pressure setting Turn current adjustment knob to test flow and set

pressure regulator 75 psi (5.2 bar) for cutting and 50

psi (3.4 bar) for gouging.

No output from power

board (PCB2)

Power board failure, or

damaged torch or lead

assembly.

Verify fault: control board (PCB3) IF LED. If Fault and

IF LEDs are illuminated, replace power board. If IF LED

is not illuminated, replace torch and lead assembly.

NOTE: OCV is 300VDC but is only available for 100

msec. Measure at J15 and J16 using a Fluke 87 or

equivalent digital multi-meter.

Power LED illuminates, all

fault LEDs extinguished, but

no air flow or firing of torch

when torch switch is pressed

When pressing torch

trigger/start switch, air flows

from torch, but no arc

Yellow cap sensing LED

illuminates

Safety circuit not satisfied

Over temp LED illuminates Temperature sensors not

satisfied

AC

Loading...

Loading...