MAINTENANCE

3-12 powermax1650 Service Manual

0

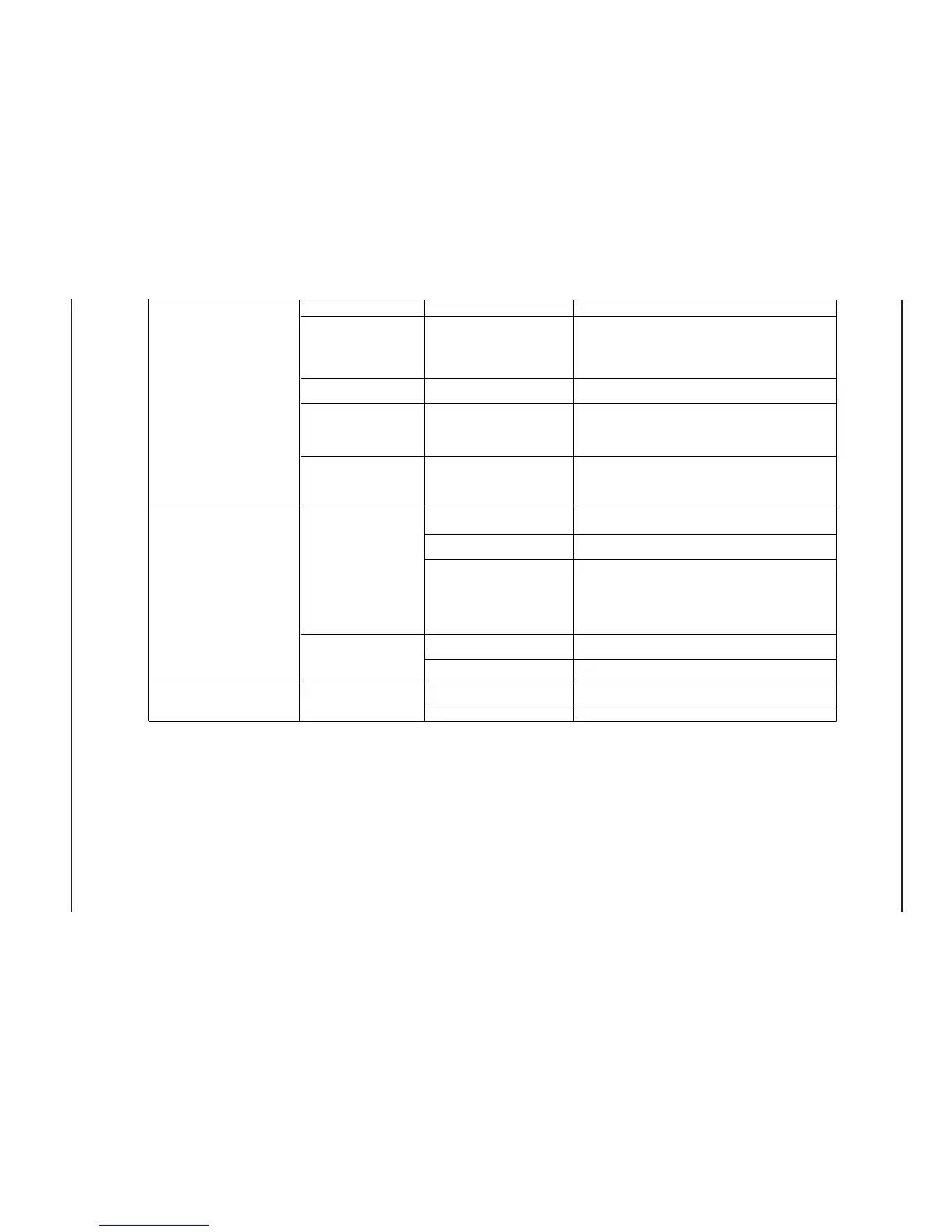

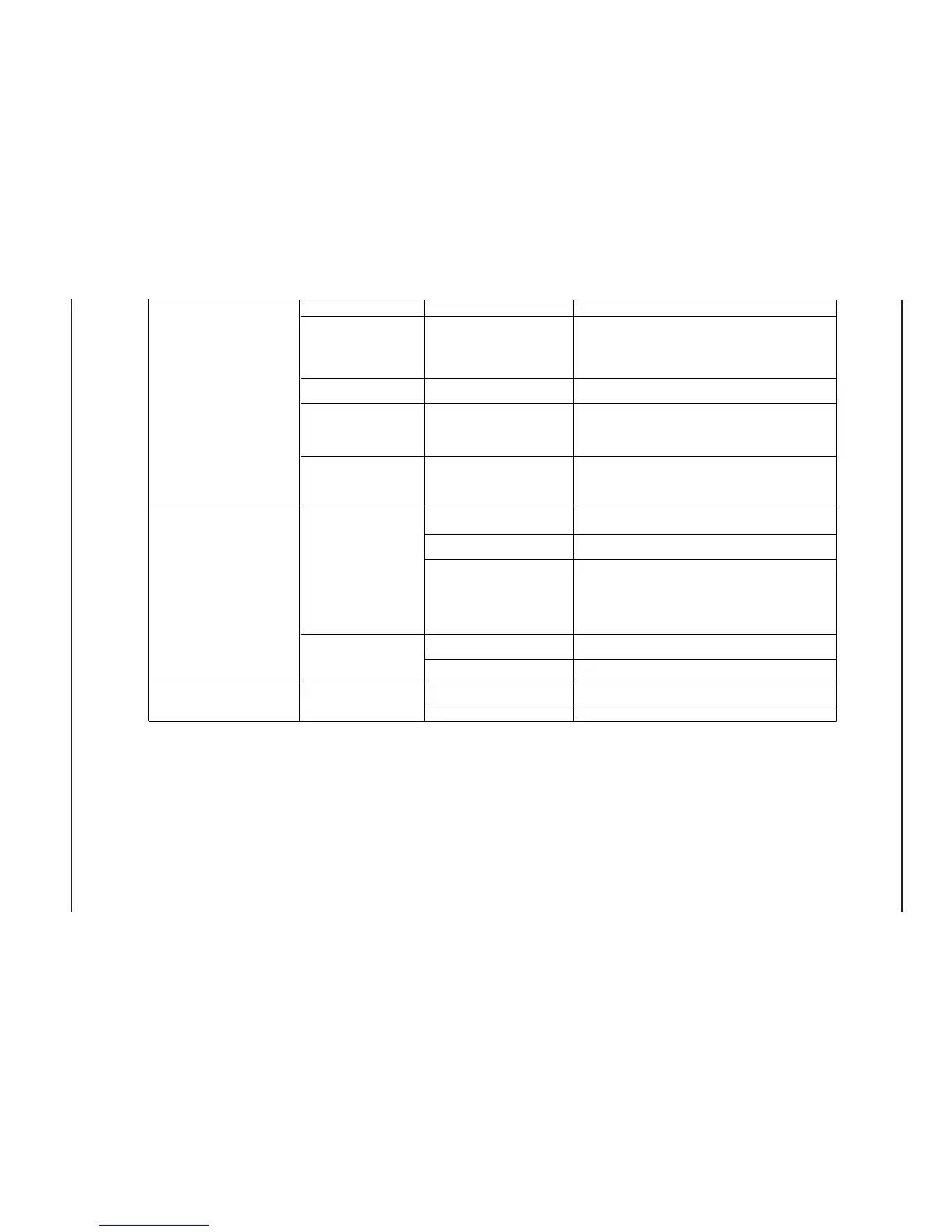

Worn consumables Worn-out consumables Replace consumables

Improper air pressure

setting or low flow

Insufficient supply or air leak

on supply line

Turn current adjust knob to test flow and set pressure

regulator to 75 psi (5.2 bar) for cutting or 50 psi (3.4

bar) for gouging. If unable to adjust to proper setting,

verify that inlet pressure is between 90 psi (6.1 bar)

and 120 psi

Moisture or contaminates in air

suppl

Add appropriate filtration and purge lines with nitrogen

to flush out oil and moisture.

Undersized electrical supply

installation:

- Breaker/fuse

- Supply wire

Verify external electrical power is installed per

specifications in section 2. Check input voltage while

trying to fire torch. Voltage drop indicates undersized

electrical supply installation.

Inverter fault or interlock Power board (PCB2) failure

If the control board (PCB2) IF LED illuminates and one

or more of the fault LEDs illuminate, then the fault is

caused by the parameter monitored by the fault LED. If

no fault LED is illuminated

Poor work lead connection

Verify work lead is attached to workpiece and

workpiece is free of rust, paint, etc.

Check continuity of work lead. Replace or repair as

re

Defective pilot arc IGBT (Q15)

Turn power OFF, remove consumables, check

resistance between plunger and work piece. If

resistance is greater than 8k ohms. Inspect work lead.

Check pilot arc IGBT resistance between two screws at

Q15 on power board. If resistance is less than 5k

Current adjustment set too low

Verify current adjust knob is at proper setting (turn to

max

.

Defective power board current

sensor

Replace power board. Can confirm power output by

measurin

with a DC current clamp meter on work

Mode switch set wrong Set mode switch to correct position.

Faulty control board (PCB3) Replace control board.

Inadequate ground

Low output from power

supply

Losing pilot arc when going

off plate while in continuous

ilot mode

Continous pilot arc does

not work.

When pressing torch

trigger/start switch, pilot arc

starts but “pops out” before

the normal 5 second time-out

period

Machine will not cut material

(does not appear to be

operating at full cutting

power)

Loading...

Loading...