3-3

STARTUP AND COMMISSIONING

DC SERIES BOILERS / WATER HEATERS DC 15-95, DC 15-96, DC 20-125, DC 33-160

The gas valve will automatically de-rate the maximum input in accordance with

the density altitude, by approximately 2% per 1,000' above sea level. The gas

valve’s zero governor will ensure that the gas:air mixture is not be affected at

altitude.

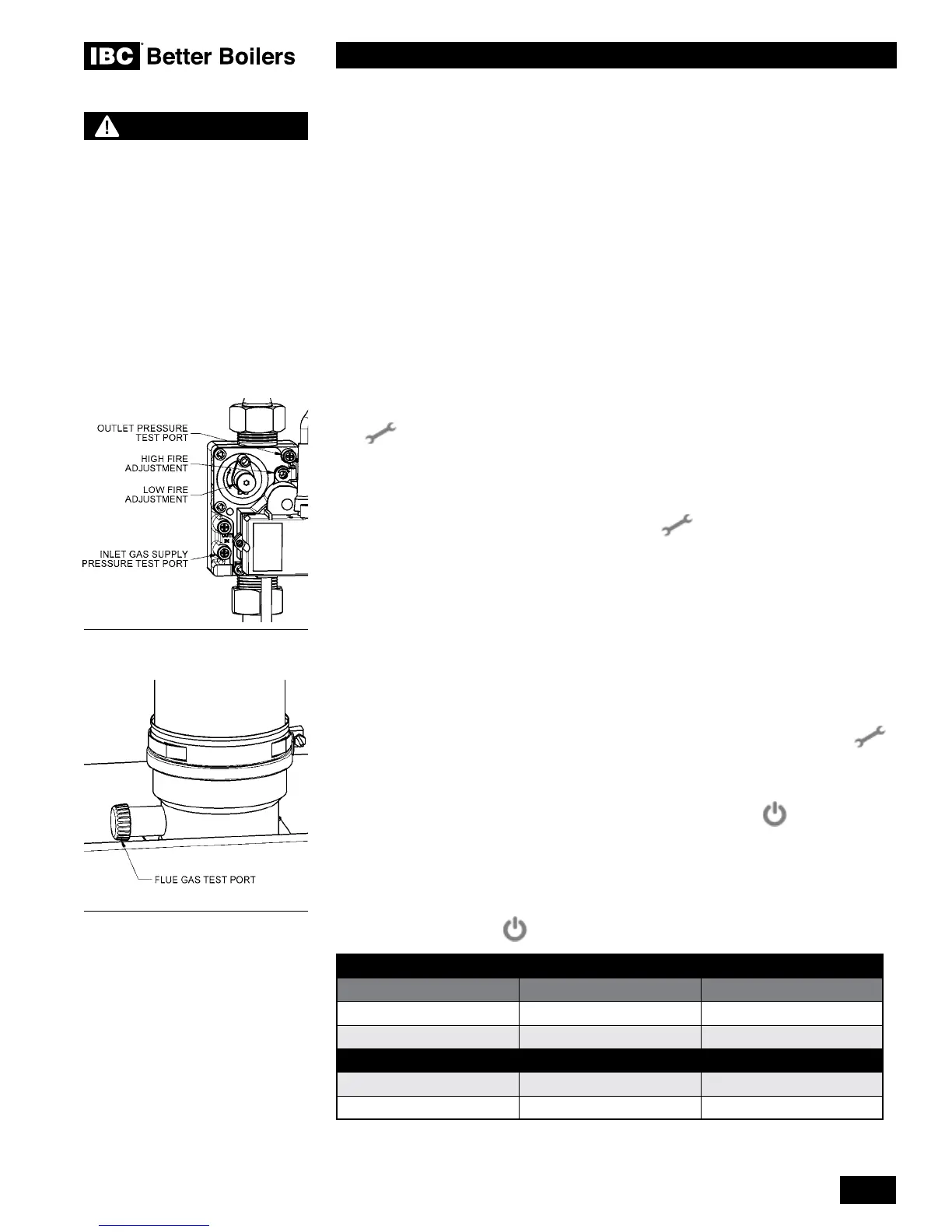

To verify the proper operation of the gas valve in the eld, the following procedure

can be carried out by a qualied technician (diagrams on this page).

1. Turn off the boiler’s gas shut off valve. With a small (1/8" or 3 mm) at

screwdriver, open the inlet gas supply pressure test port by turning its

center-screw 1 full turn counterclockwise. Attach a manometer to the

pressure test port and turn on gas to appliance. Static manometer reading

should be ideally 7" w.c., for Natural Gas and 11" w.c. for Propane. Minimum

and maximum static pressure should be between 7" and 14" w.c. Monitor

pressure throughout the commissioning procedure. Pressure may droop up

to 1" to 2" w.c. at high re.

2. Allow the boiler / water heater to ignite / run against a large load, to maintain

high re. Enter the High Fire Manual Mode by pressing both the Service

and Plus

+

buttons together twice. “H” will be showing in the service

display. NOTE: Do not make any adjustments if an “h” is showing in the

service display. Allow the boiler / water heater to operate at High Fire for 3

minutes to stabilize. (The boiler / water heater will operate in manual mode

for 10 minutes then switch back to the normal operating mode. To extend

manual mode operation, press the Service and Plus

+

together twice

while the boiler / water heater is operating in manual mode to reset the timer

for 10 more minutes.) Pressing and holding

+

for more than 2 seconds while

in the Service Mode will display the Flame Current in DC microamps. Expect

approximately 9.8μA at High Fire (6.5μA or higher at Low Fire).

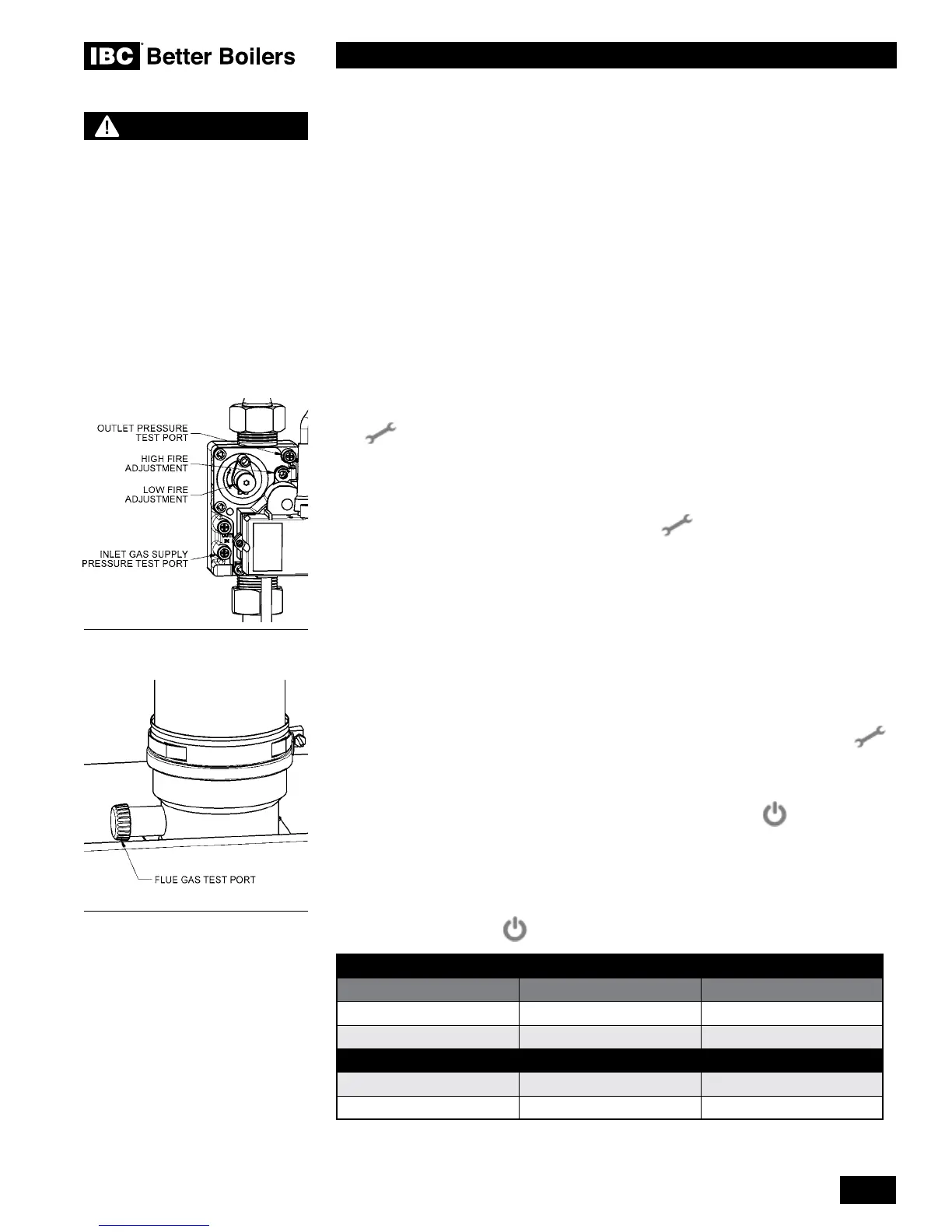

3. With a combustion analyzer probe in the ue gas test port, turn the High Fire

(Gas : Air Ratio Adjustment) screw (see diagrams on this page) to achieve

results. This screw offers very ne adjustment, and may require several

turns. Clockwise richens, i.e. raises the CO

2

value.

NOTE: Clock the gas meter to conrm full maximum rating plate input. Check

the measured results with Table 11 - High Fire.

4. Switch the boiler / water heater to low re by pressing both the Service

button and Minus

-

buttons at the same time. The boiler / water heater

will drop to low re. “L” will be showing in the service display. Compare the

readings with Table 11 - Low Fire.

5. Switch off the boiler / water heater by pressing the On/Off button. Turn

off the gas at the boiler / water heater gas shut off valve. Remove the ue

gas analyzer from the test port and reinstall the test port cap. Remove the

gas pressure manometer from the gas valve and close the test port. Turn on

the gas at the boiler / water heater’s gas shut off valve. Ensure there are no

gas leaks and reinstall the front cover. Turn on the boiler / water heater by

pressing the On/Off button.

CO

2

VALUE (%) AT HIGH FIRE WITH THE FRONT COVER OPEN

NATURAL GAS PROPANE

Max. CO

2

value 10.1% 11.5%

Min. CO

2

value 9.1% 9.8%

CO

2

VALUE (%) AT LOW FIRE WITH THE FRONT COVER OPEN

Max. CO

2

value = value at High = value at High – 0.3%

Min. CO

2

value 9.1% 9.5%

Table 11: CO

2

Values and High and Low Fire

Gas Valve Adjust

Flue gas test port plug

WARNING

Check the rating plate of the

boiler / water heater to ensure

it is congured for the fuel

you are using. If the fuel is

incorrect for the appliance,

a conversion kit must be

ordered from IBC and the gas

valve adjusted accordingly.

Failure to perform the

required fuel conversion can

result in an immediate hazard.

Loading...

Loading...