30

INSTALLATION

icos system - Installation and Servicing

35

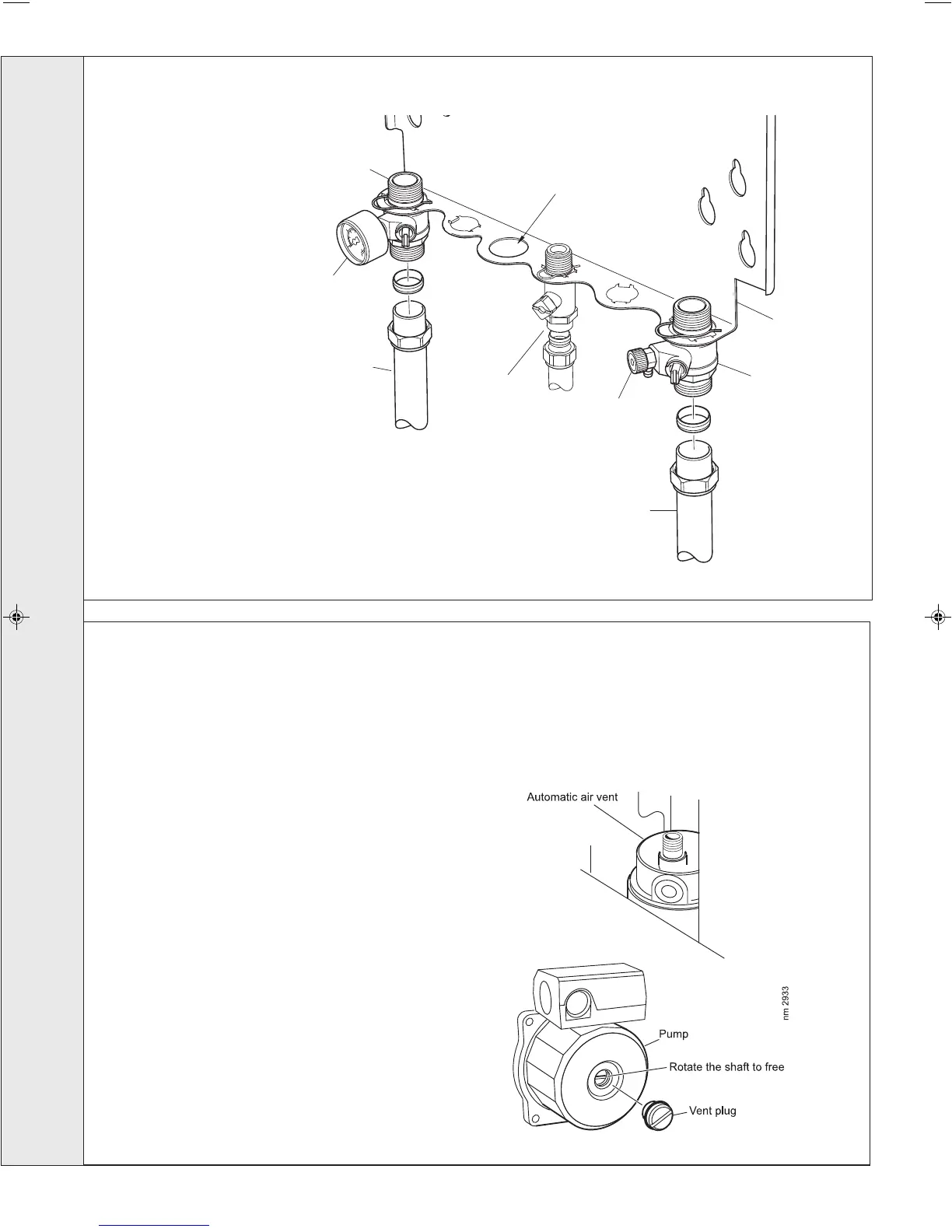

FILLING

1. Remove the boiler front and sealing panels. Refer to Frames 47 & 48.

2. Swing the control box down into the servicing position - Refer to Frame 49.

3. Ensure that the isolating valves are open.

4. Fill and vent the system. Check for water soundness.

IMPORTANT - when filling:

a. When filling, there may be a slight water leak from the vent

therefore electrical connections should be protected.

b. Bleed any air from the pump and ensure that it is free to rotate.

i. Remove the vent plug

ii. Using a screwdriver, rotate the shaft several times

iii. Replace the vent plug.

Note. Some slight water leakage will occur.

34

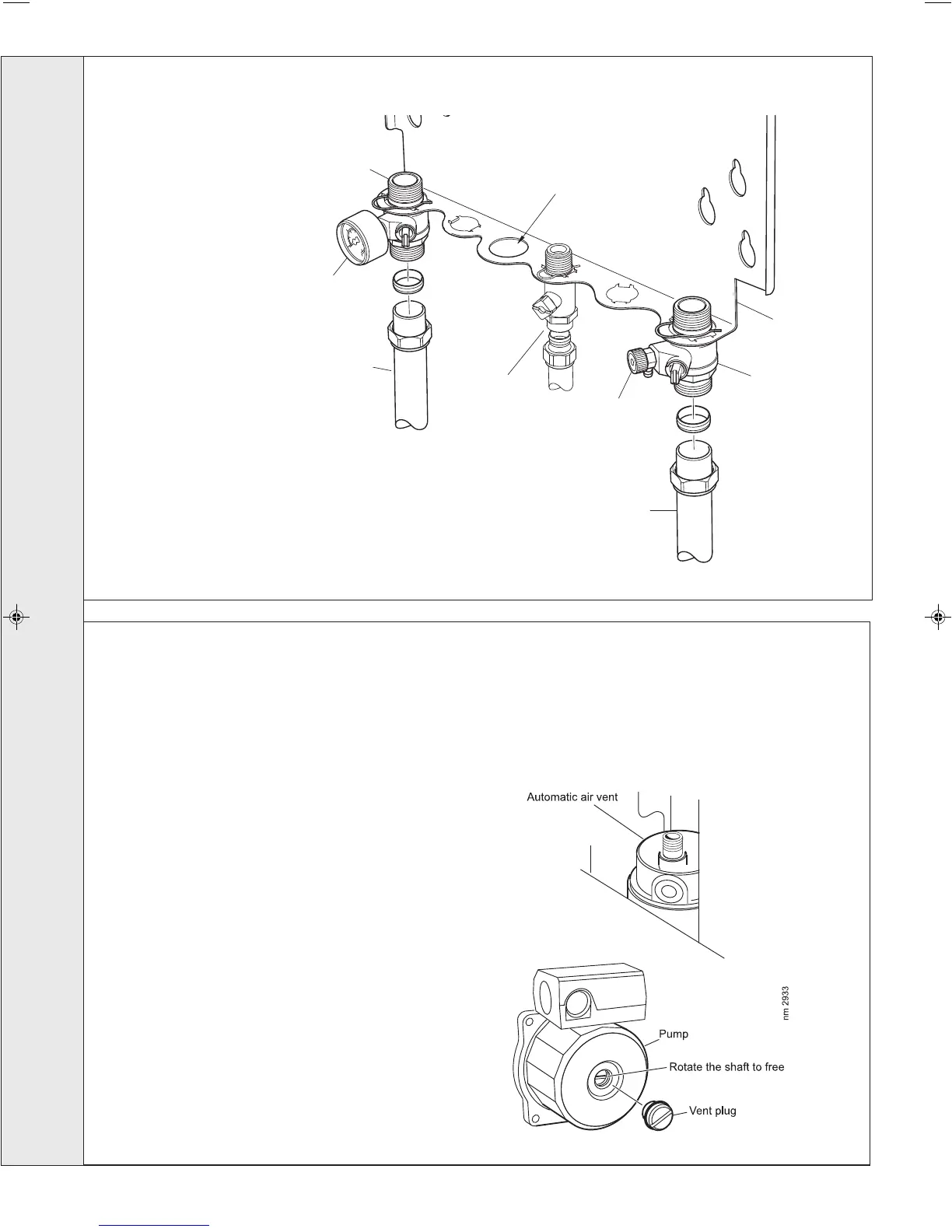

WATER CONNECTIONS

nm8461

22mm copper pipe

Isolating valve

(shown in the

open position)

Piping frame

Drain

point

Condensate drain

pipe located here

22mm copper pipe

Isolating valve

(shown in the

open position)

Pressure gauge

FLOW

RETURN

Compression

gas cock

Notes.

1. For heating loads in excess of 60,000 Btu/h

use 28mm x 22mm connectors to connect the

boiler flow and return pipes to 28mm system

pipework.

2. Do not subject any of the isolating valves to

heat as the seals may be damaged.

INSTALLATION

Loading...

Loading...