6

GENERAL

icos system - Installation and Servicing

1

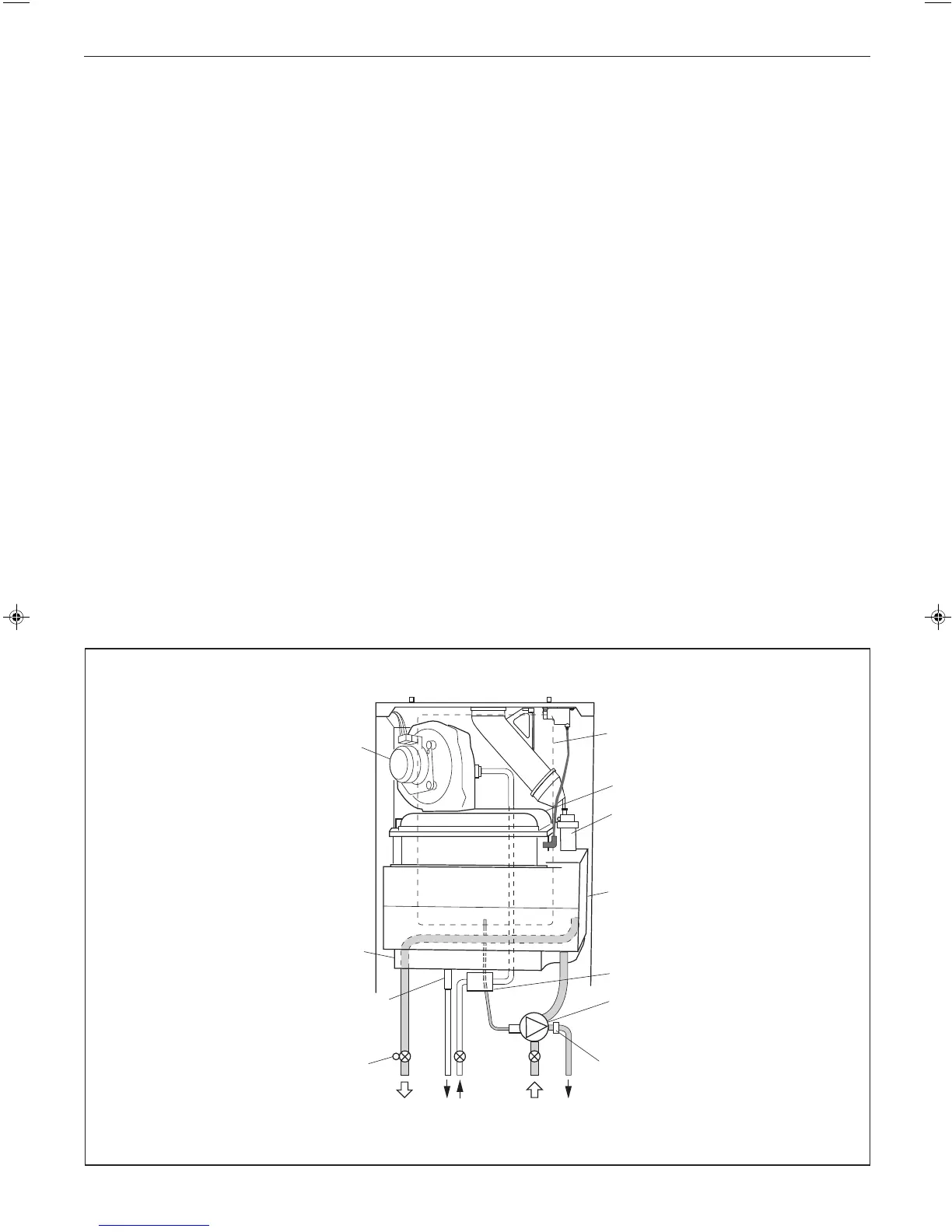

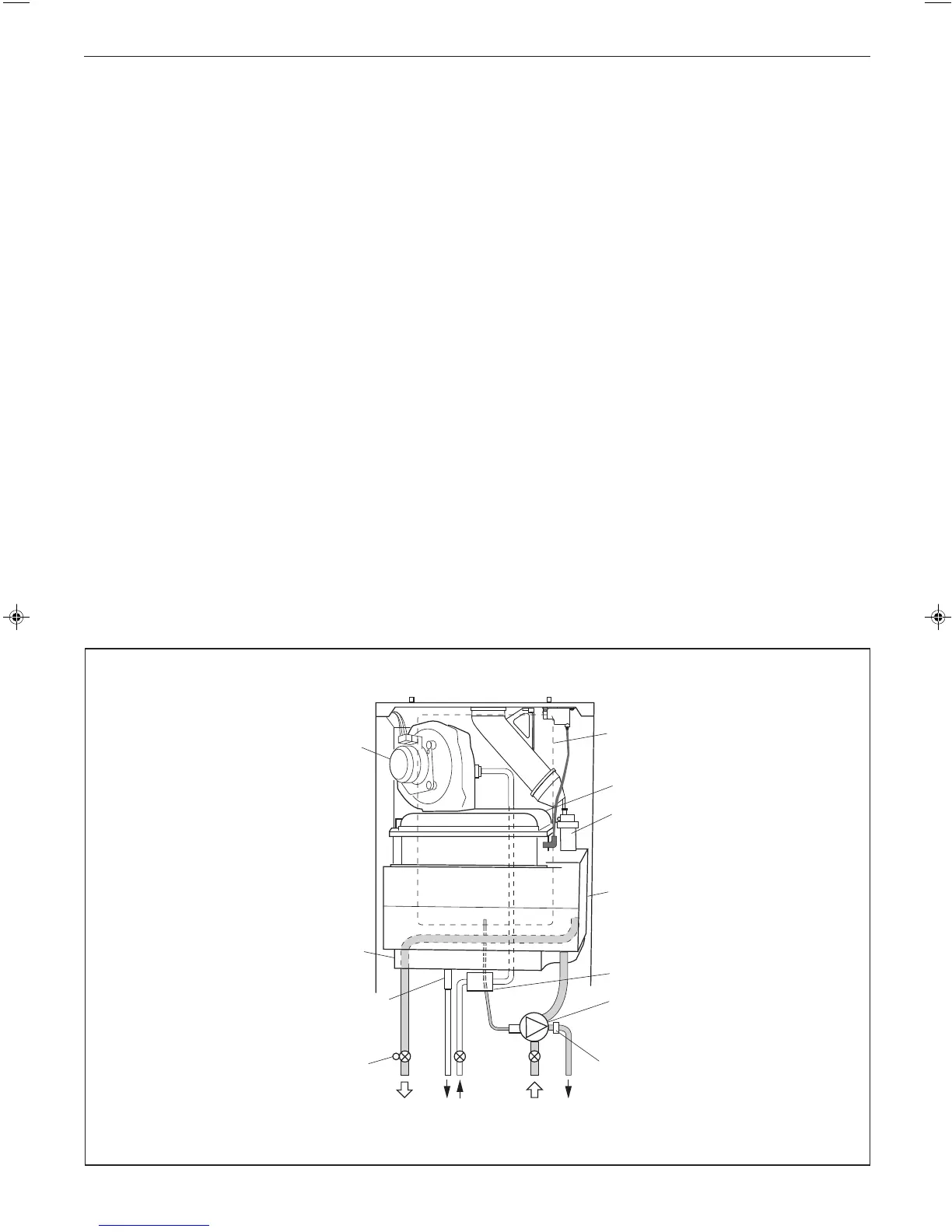

BOILER WATER CIRCUIT DIAGRAM

INTRODUCTION

The icos system HE range is a cast aluminium wall mounted,

full sequence, automatic spark ignition, low water content,

fanned flue, high efficiency, condensing system gas boiler.

Note. Due to the high efficiency of the boiler a plume of water

vapour will form at the terminal during operation.

The output is fully modulating with a range of:

8.8 to 23.4 kW (30,000 to 80,000 Btu/h)

The boiler is supplied fully assembled with circulating pump,

pressure gauge, safety valve and expansion vessel.

Variable temperature control is fitted on the user control.

The boiler casing is of white painted coated mild steel with the

user controls capable of being mounted remotely from the

boiler if the option is required.

The heat exchanger is of cast aluminium.

The boiler is suitable for connection to fully pumped, sealed

water systems ONLY.

Adequate arrangements for completely draining the system by

provision of drain cocks MUST be provided in the installation

pipework.

Pipework from the boiler is routed downwards as standard, but

may be routed upwards behind the boiler using the stand-off

frame (supplied in a separate kit).

OPERATION

When there is a demand for heat, the heating system is supplied

at the selected temperature of between 30

o

C and 82

o

C.

Refer also to Frame 1 - 'Boiler Water Circuit Diagram'

Expansion

vessel

Automatic

air vent

Heat

exchanger

Gas valve

Pump

Safety

relief valve

Condensate

'S' trap

Water

pressure

gauge

Sump

Fan

Burner

Flow

Gas

Condensate

drain

Discharge

pipe

nm9434

Return

The boiler features a comprehensive diagnostic system which

gives detailed information on the boiler status when operating,

and performance of key components to aid commissioning

and fault finding.

SAFE HANDLING

This boiler may require 2 or more operatives to move it to its

installation site, remove it from its packaging base and during

movement into its installation location. Manoeuvring the boiler

may include the use of a sack truck and involve lifting, pushing

and pulling.

Caution should be exercised during these operations.

Operatives should be knowledgeable in handling techniques

when performing these tasks and the following precautions

should be considered:

• Grip the boiler at the base.

• Be physically capable.

• Use PPE as appropriate, e.g. gloves, safety footwear.

During all manoeuvres and handling actions, every attempt

should be made to ensure the following unless unavoidable

and/or the weight is light.

• Keep back straight.

• Avoid twisting at the waist.

• Avoid upper body/top heavy bending.

• Always grip with the palm of the hand.

• Use designated hand holds.

• Keep load as close to the body as possible.

• Always use assistance if required.

Loading...

Loading...