Page 11 www.123filter.com | +1 (678) 261-7611 | support@123filter.com

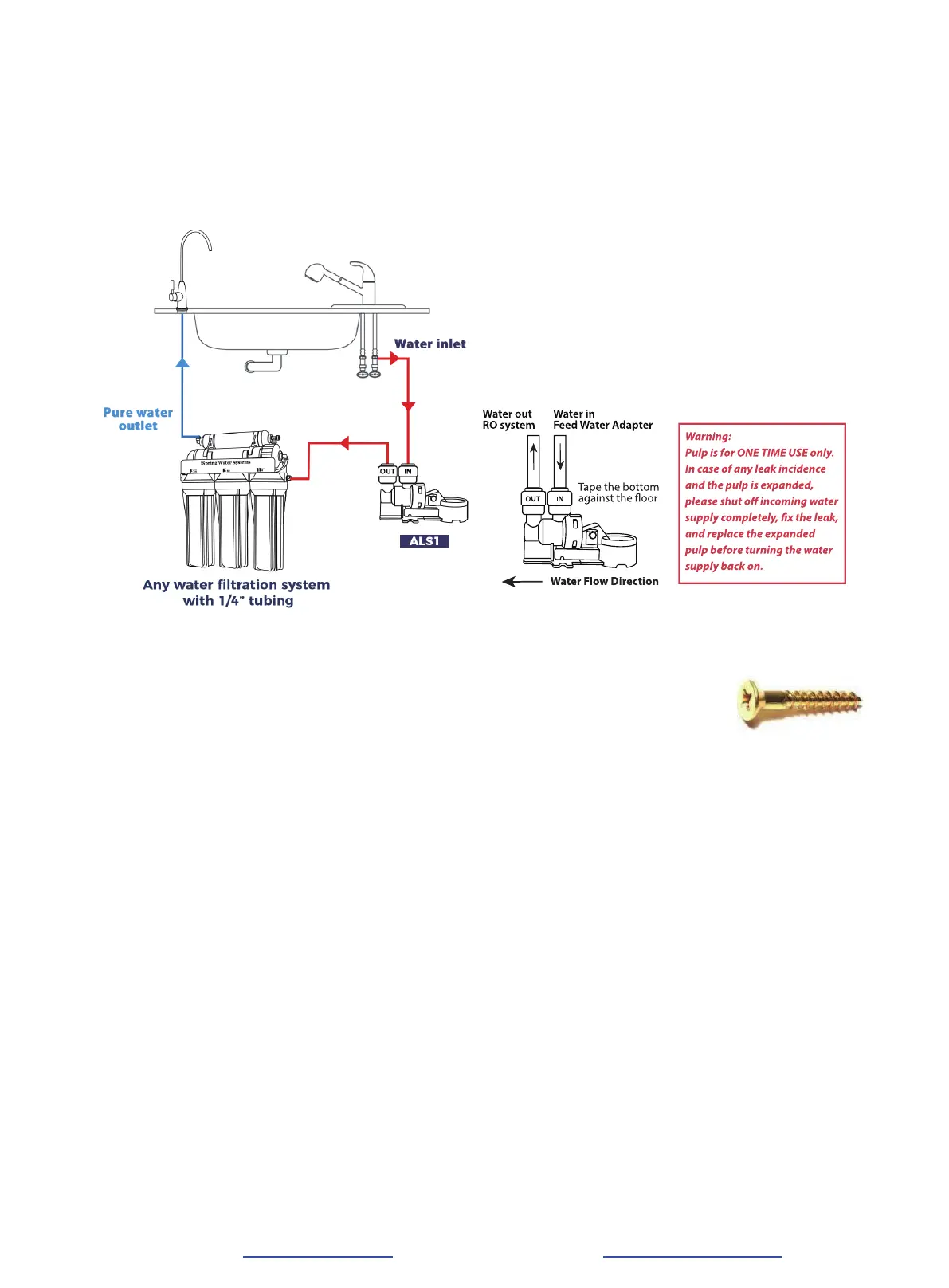

Step 6: Leak Stop Valve (ALS1) Installation

The Leak Stop Valve is a reusable mechanical leakage protector. Whenever a water leakage is

detected, it will shut down the feed water.

Step 6. a. Make sure the end of the tubing is cut square before connecting it to the fitting.

Step 6. b. Follow the water flow direction indicated on the Leak Stop Valve to connect it to the

water inlet pipeline.

Step 6. c. Tape the bottom of the Leak Stop Valve against the floor.

Step 7: Mounting the System (Optional)

• Mounting the system is NOT required. The system does NOT need to be

mounted to work correctly.

• Please note if the system is to be mounted, it is recommended to use two 10

x 1-1/4 Phillips Flat Wood Screws (not included). This will make replacing

filter cartridges easier.

Note: If you plan on mounting/hanging the system, it is highly recommended to include supports

under each of the bottom three housings. Supports under the housings will take the water weight

off the housing

threads and ensure the thread strength does not decay over the years.

Step 8: System Start-up

Note for model#RCC1DP: You may now plug in the booster pump to an outlet. The pump will

not turn on until the water is flowing.

Step 8. a. Make sure no tubings are kinked. Place a towel under the system to catch any possible

water leaks.

Step 8. b. Disconnect the RO membrane housing cap inlet tubing. Turn on the water inlet, and

flush the first three stages into a bucket until the

water turns clear. The water may appear

black at first due to loose carbon from new carbon filters.

Step 8. c. Once the water is clear, shut off the water inlet and reconnect the tubing to the RO

membrane housing cap. You will want to flush the first three stages like this whenever

they are changed.

Step 8. d. Open the pure water outlet. Slowly open the water inlet and check for any leaks. The

top 3 causes of leaks are 1) The tubing is not fully inserted into the quick-connect fitting.

2) T

he O-ring is not in the correct place or is kinked. 3) The Housing/Cap is not

tightened properly or is misaligned with the threads.

Loading...

Loading...