III. Engine Servicing Procedures

U L-Series Diesel 25

Injector Pop-off Test

WARNING: FLUID FROM THE NOZZLE TESTER WILL SPRAY OUT UNDER

GREAT PRESSURE. IT CAN EASILY PUNCTURE A PERSON’S SKIN. KEEP

YOUR HANDS AWAY FROM THE NOZZLE TESTER AT ALL TIMES.

Use the following procedure to check

nozzle opening pressure, spray pattern,

chatter and leakage:

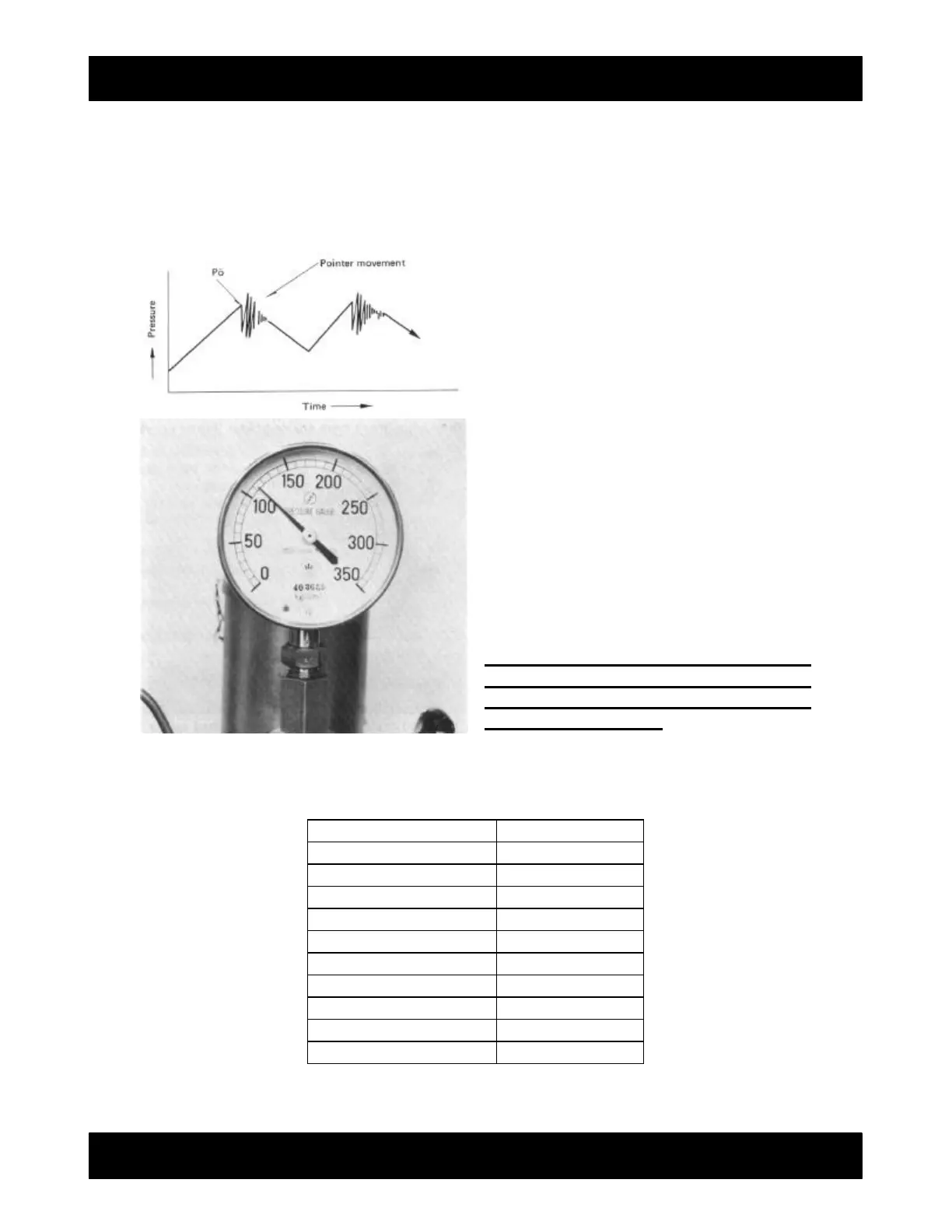

Mount the nozzle and holder assembly to

the gauge (J28829) and bleed the system of

air.

Open the pressure gauge valve and pump

the lever at a rate of one stroke per second.

Then check the opening pressure. When the

pressure gauge pointer decreases rapidly,

read pop-off value. (Refer to engine’s

specification sheet for values. An Indirect

Injection will have lower readings than a

Direct Injection engine.)

IMPORTANT! If the nozzle opening

pressure is not steady or cannot be

checked the trouble is with the nozzle

assembling procedure.

If the nozzle “pop-off” pressure does not meet factory pressures, disassemble the nozzle

and make a shim adjustment. The following size shims are available through AIPDN.

Shim Part Number Shim Size

mm

894176-9620 0.10

894176-9630 0.20

894176-9640 0.30

894176-9650 0.40

894176-9660 0.50

894176-9670 0.52

894176-9680 0.54

894176-9690 0.56

894176-9700 0.58

894176-9710 0.80

Loading...

Loading...