III. Engine Servicing Procedures

U L-Series Diesel 26

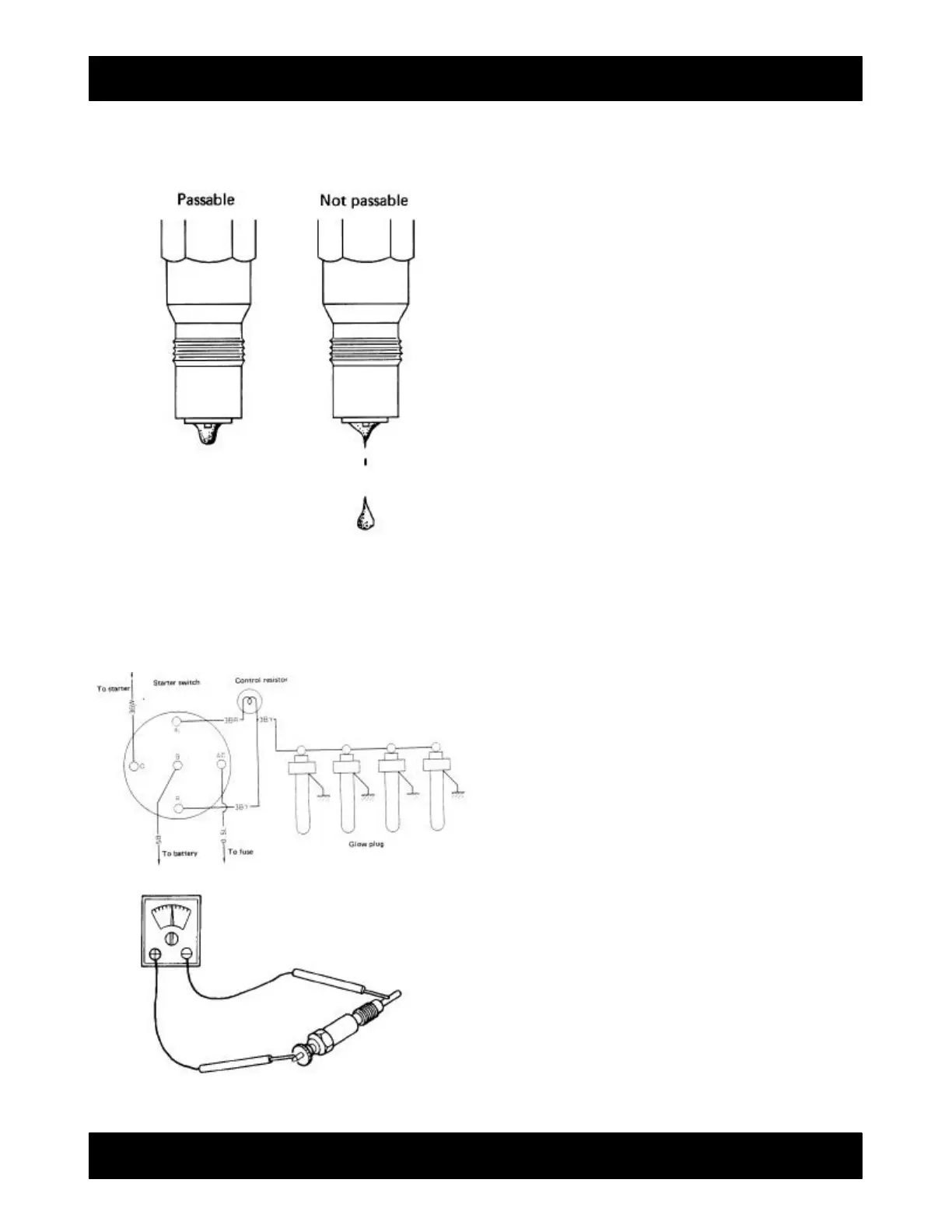

Injector Leak Test

The leak test should be conducted

immediately following the nozzle opening

pressure adjustment check.

⇒ Wipe the nozzle with a clean shop

towel.

⇒ Decrease the tester pressure about 20

less than the pop-off pressure

and maintain the position.

⇒ There should be no fuel discharge from

the nozzle for at least 10 seconds.

⇒ Re-clean or replace any nozzle that

doesn’t meet the criteria.

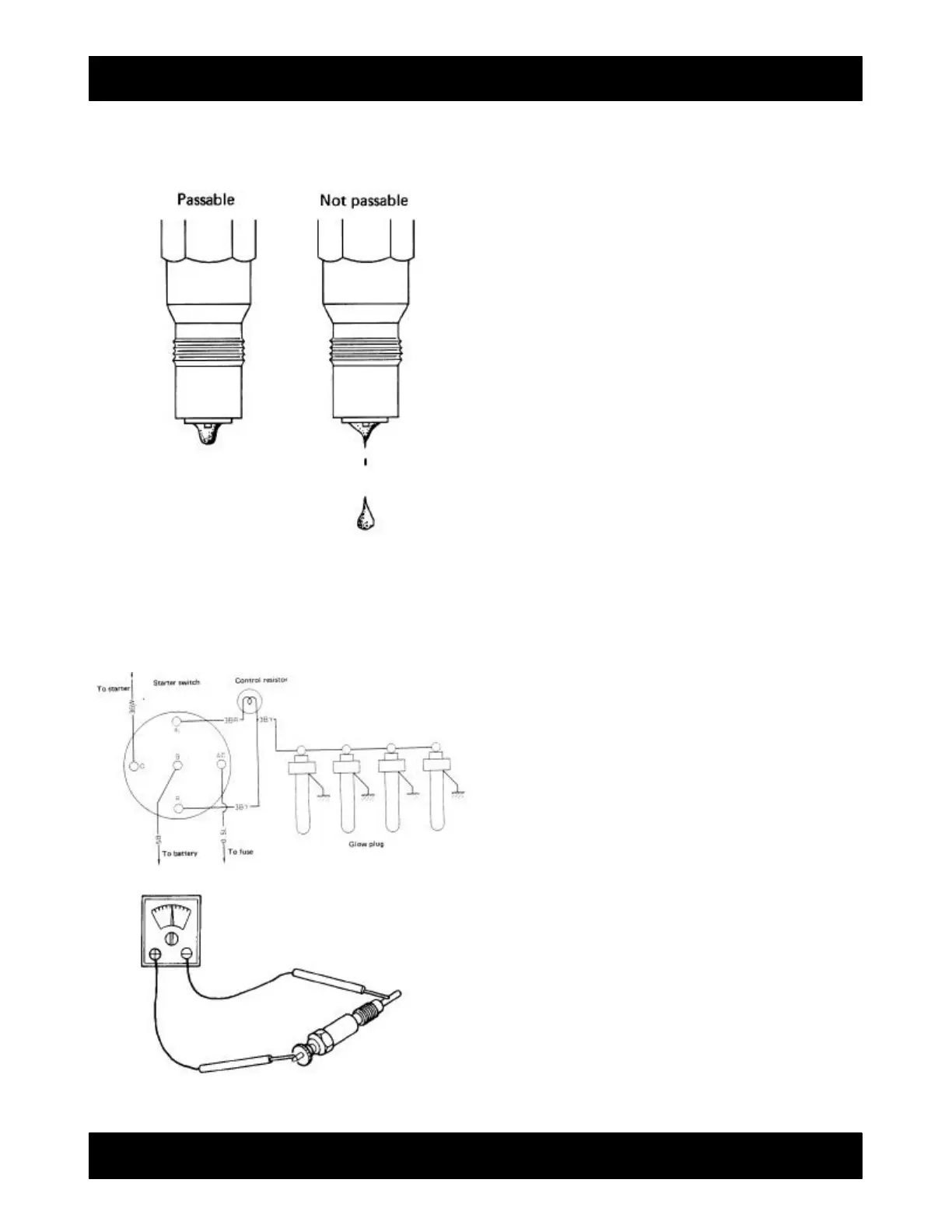

Glow Plug Inspection

The following procedure tests the

resistance value of the glow plug.

The test can be performed on or off the

engine.

Total glow plug resistance value should be

≤ 0.9 ohms.

On engine service:

• Remove the buss bar from the glow plug.

• Attach the DVOM red lead to the to the tip of

the glow plug.

Attach the DVOM black lead to a good ground

source. Verify the ground integrity by testing it

with the DVOM.

Off engine service:

• Disconnect and remove glow plug.

• Place DVOM leads across glow plug (one lead

at each end) to obtain resistance reading.

Loading...

Loading...