22 Please see operator manual for full details.

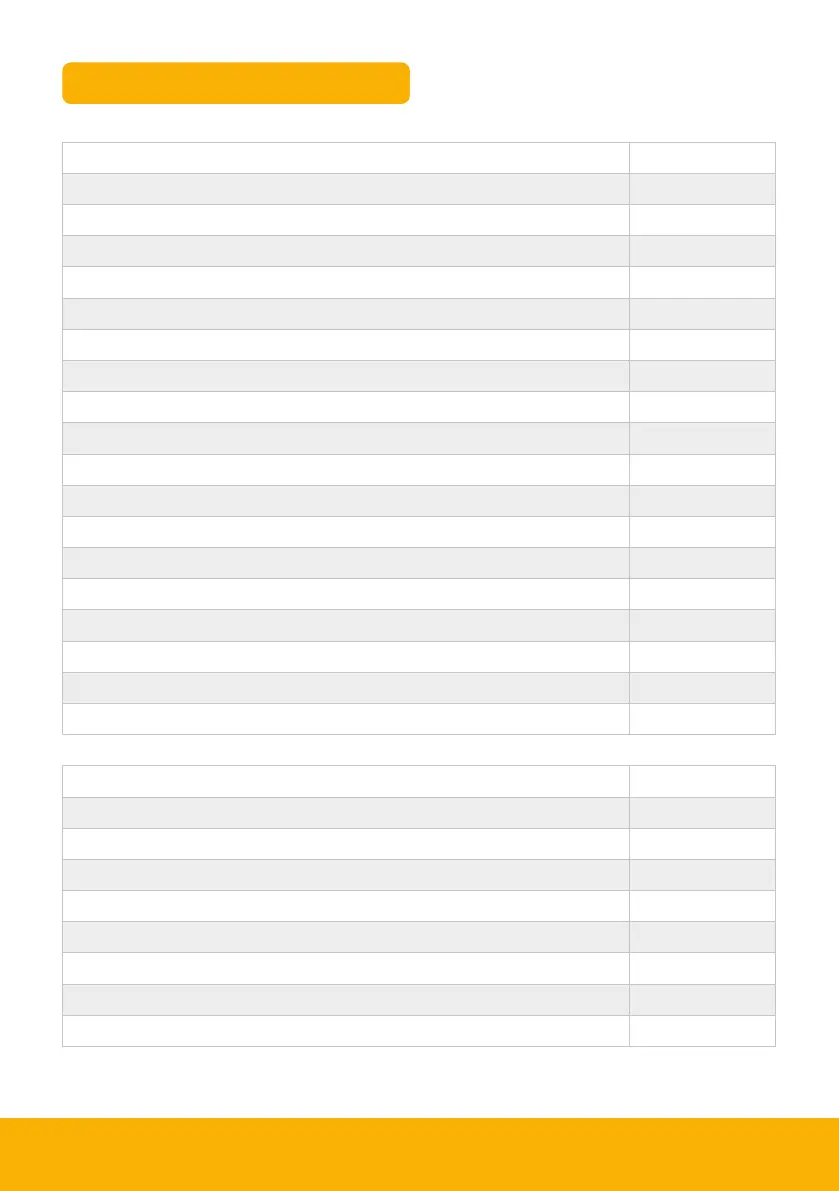

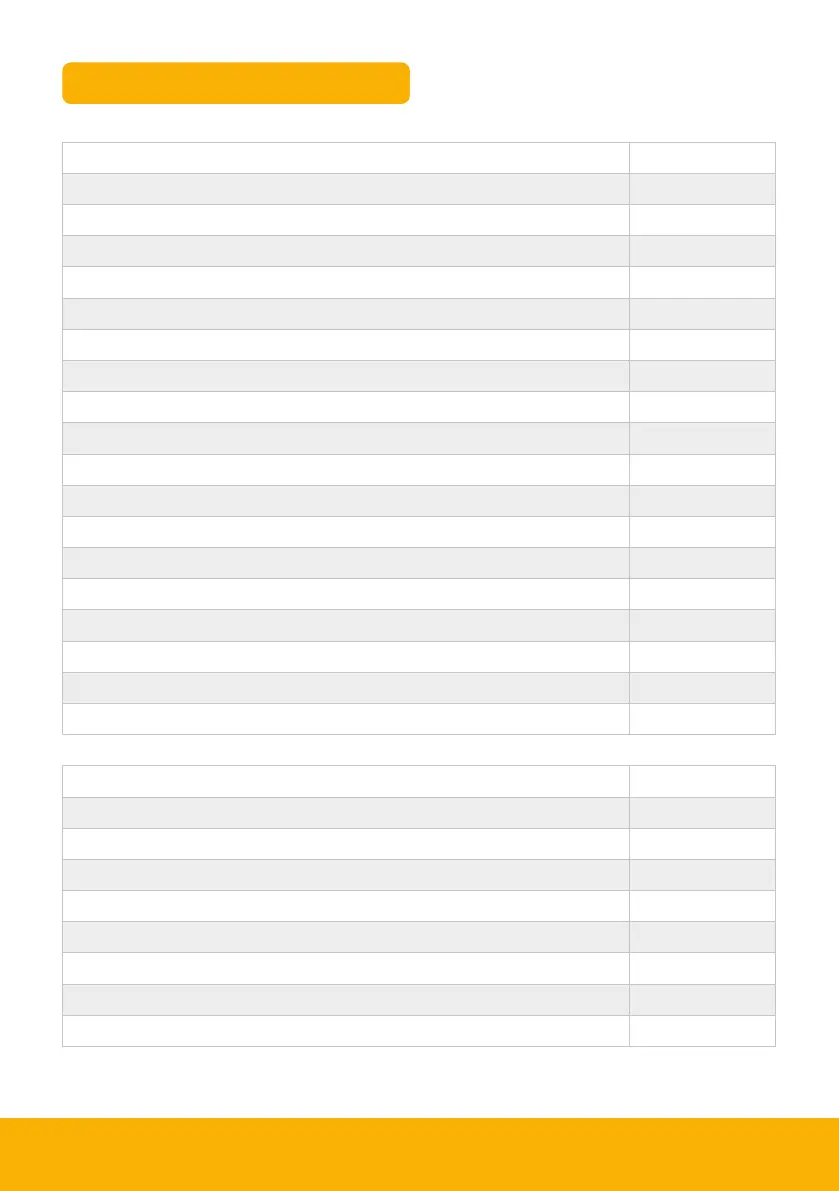

Weekly Checks (50h) Check

Grease slew ring bearing Lubricate

Clean cooling pack Clean

Check condition and tension of tracks Visual check

Check hydraulic hoses / pipework for leaks and damage Visual check

Check condition of the rams Visual check

Check the condition of the electrical wiring Visual check

Clean the battery terminals Clean

Check the operation of the battery isolator Operate

Daily Checks (10h) Check

Check condition of attachments / optional equipment

Visual check

Grease attachments / optional equipment as required

Lubricate

Clean bodywork and framework

Clean

Check condition of bodywork and framework

Visual check

Check condition of cab/canopy including seat belt

Visual check

Check engine for leaks and oil level

Visual check

Check condition of drive belt

Visual check

Check fuel system for leaks and contamination

Visual check

Drain water from water separator on fuel filter

Clean

Check engine coolant for leaks, contamination and level

Visual check

Check condition of cooling pack and system

Visual check

Check hydraulic oil level

Visual check

Check window washer fluid level

Visual check

Check the condition of the fire extinguisher

Visual check

Check operation of all services i.e. excavator, dozer etc.

Operate

Check operation of all electrical equipment i.e horn, alarms etc.

Operate

Check operation of the hour meter

Visual check

Check the track and running gear operation

Operate

Service/Maintenance Schedule

Please refer to the operators handbook for a complete service and maintenance guide.

Loading...

Loading...