Operation

Moving a Disabled Machine

37 9831/3200-3 37

Moving a Disabled Machine

General

Notice: Following any incident, thoroughly inspect the machine. Do not raise the platform until you are sure

that all damage has been repaired and that all controls are operating correctly. Test all functions first from

the ground controller, then from the platform controller.

WARNING Do not use the platform controller to release the platform when it is stuck, snagged or caught.

In this case, use the ground controller only when there are no persons on the platform.

If the machine becomes disabled, the machine must be made safe, lifted onto a transporter and moved to a

location where it can be repaired.

Towing, winching or pushing the machine without following the correct procedure will damage parts of the

hydraulic system. If possible, repair the disabled machine where it stands.

Lower the Platform (Emergency Operation)

The lowering alarm does not sound while lowering but if the machine is switched on the fault alarm will sound

due to lowering without electrical controls. Lowering may continue.

To lower the platform in emergency conditions:

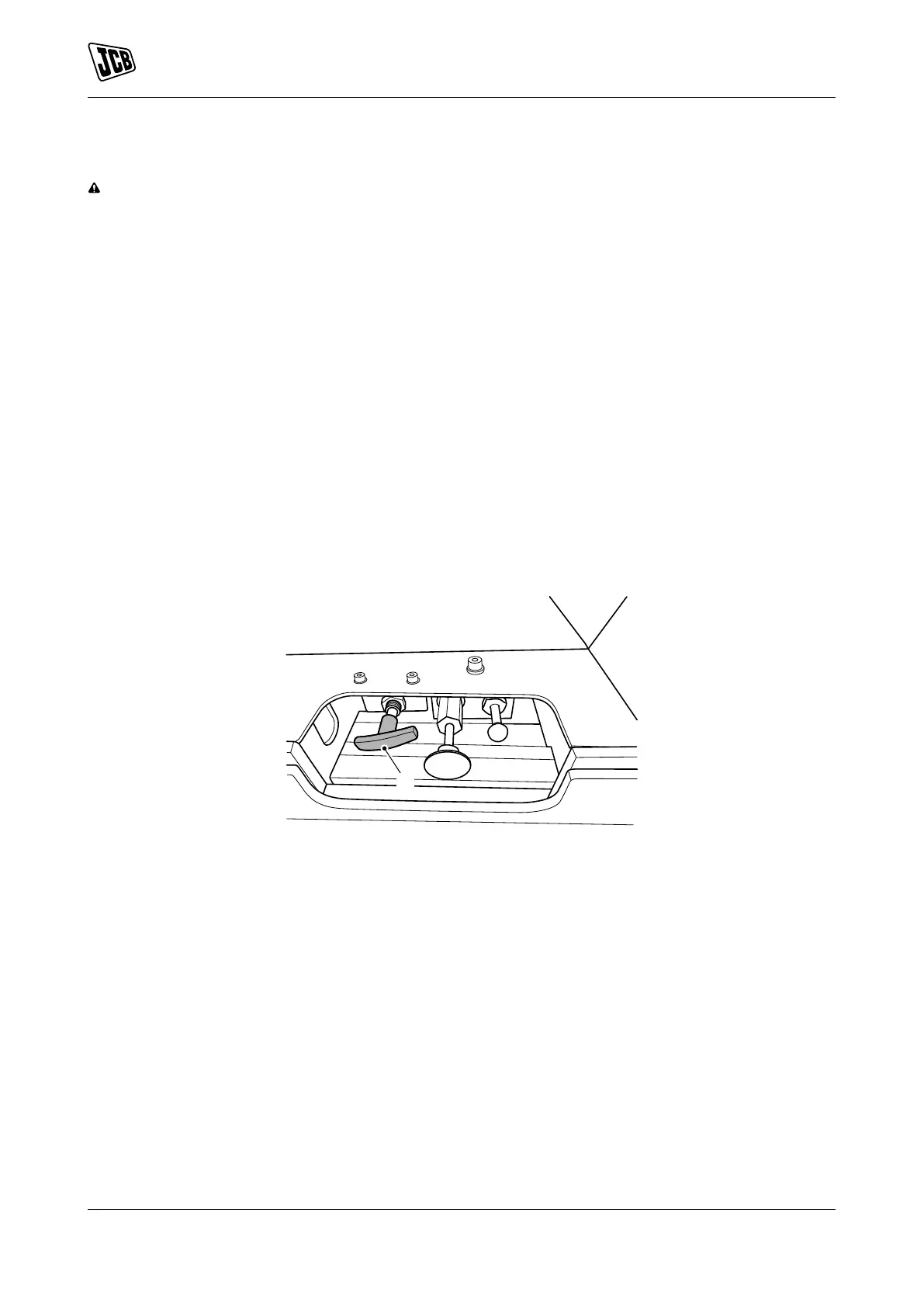

1. Pull out the emergency lowering lever. Refer to Figure 27.

2. Release the lever to stop the operation.

Figure 27.

A Emergency lowering lever

Brake Release Function

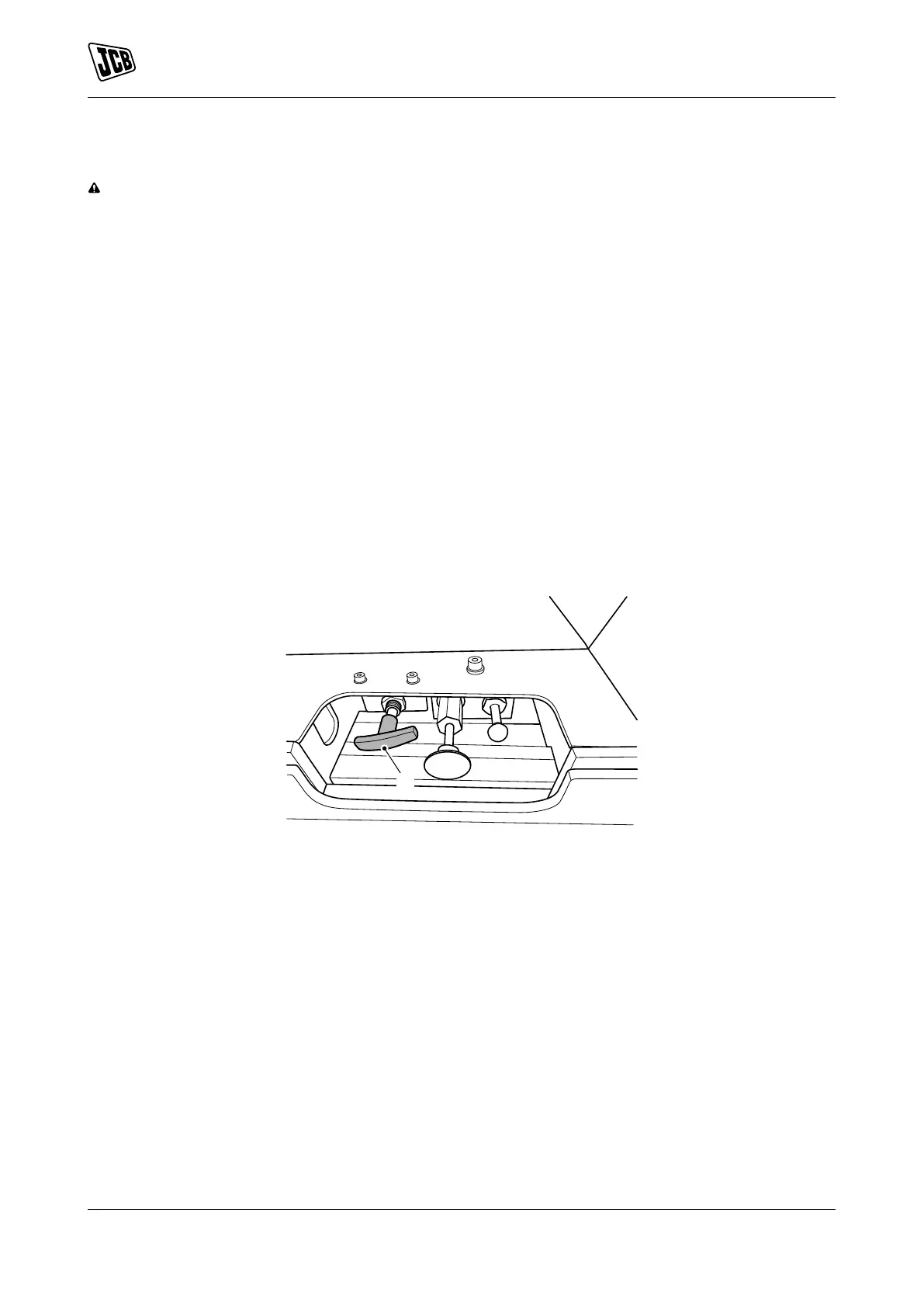

1. Put blocks at the front and rear of all four wheels. Make sure they are securely in place.

2. The release valve is at the back of the chassis.

3. Push in the black brake release handle to close the brake valve and trap the brake pressure. Refer to

Figure 28.

4. Firmly pump the red brake release handle as required to release the brake. Refer to Figure 28.

5. Pull the black handle out after the machine is recovered to re-apply the brakes.

Loading...

Loading...