CONFIDENTIAL PROPERTY OF JCM GLOBAL DRAFT 5 © 2010, Japan CashMachine Co, Limited

4

iVIZION™ Series Next-Generation Banknote Acceptor Integration Guide

Structural Specifications

This section provides installation and operating

instructions for the iVIZION™ Series Banknote

Acceptor Unit. The information within contains the

following features:

• Installation Process

• DIP Switch Configurations

• Connector Pin Assignments

• Preventive Maintenance

• Clearing Banknote Jam

• Cleaning

• Interface Schematic

• Operational Flowchart

I

NSTALLATION

P

ROCESS

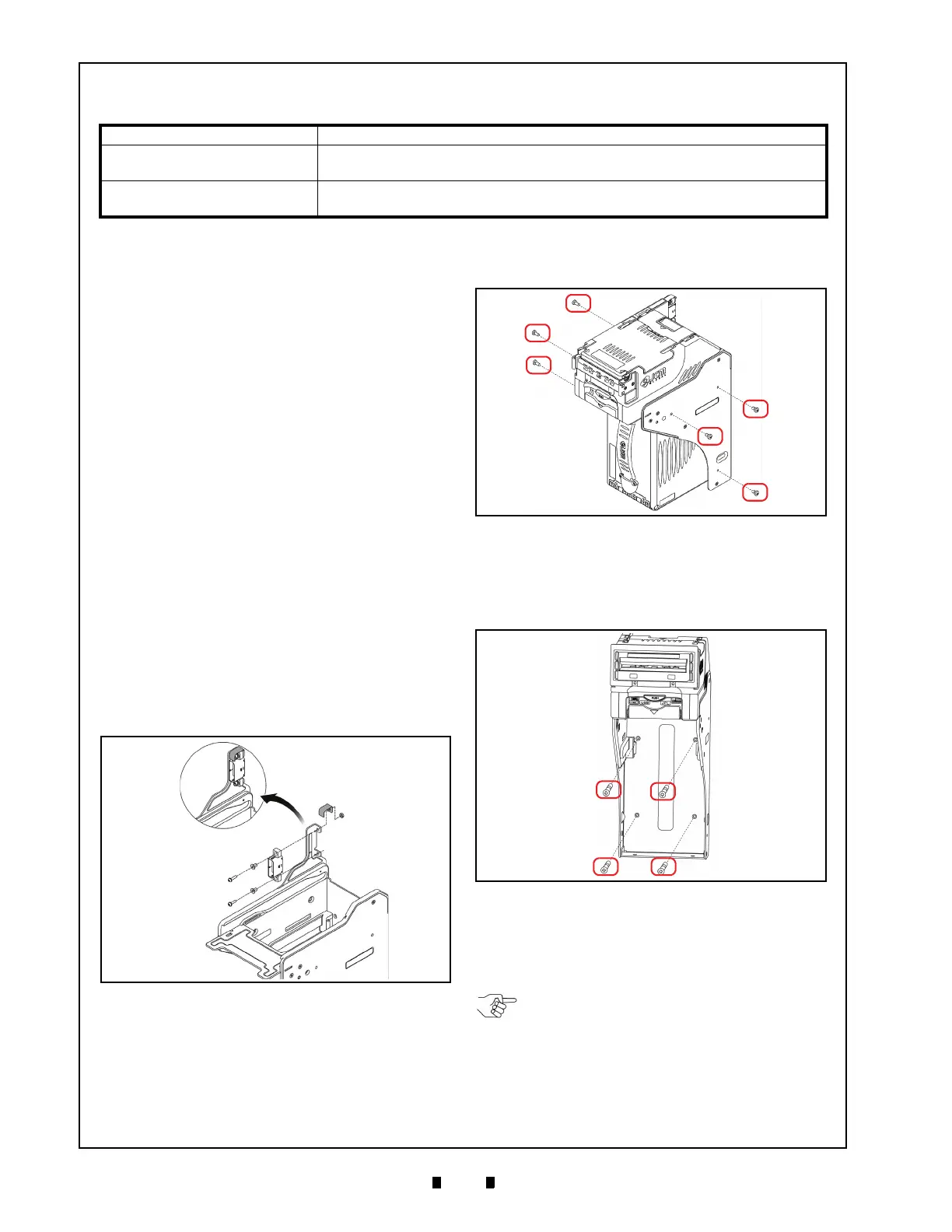

Mounting holes are provided in each Frame Unit to

attach the iVIZION™ to a related Machine during

installation. Select and perform the following steps

to install the iVIZION™ Unit:

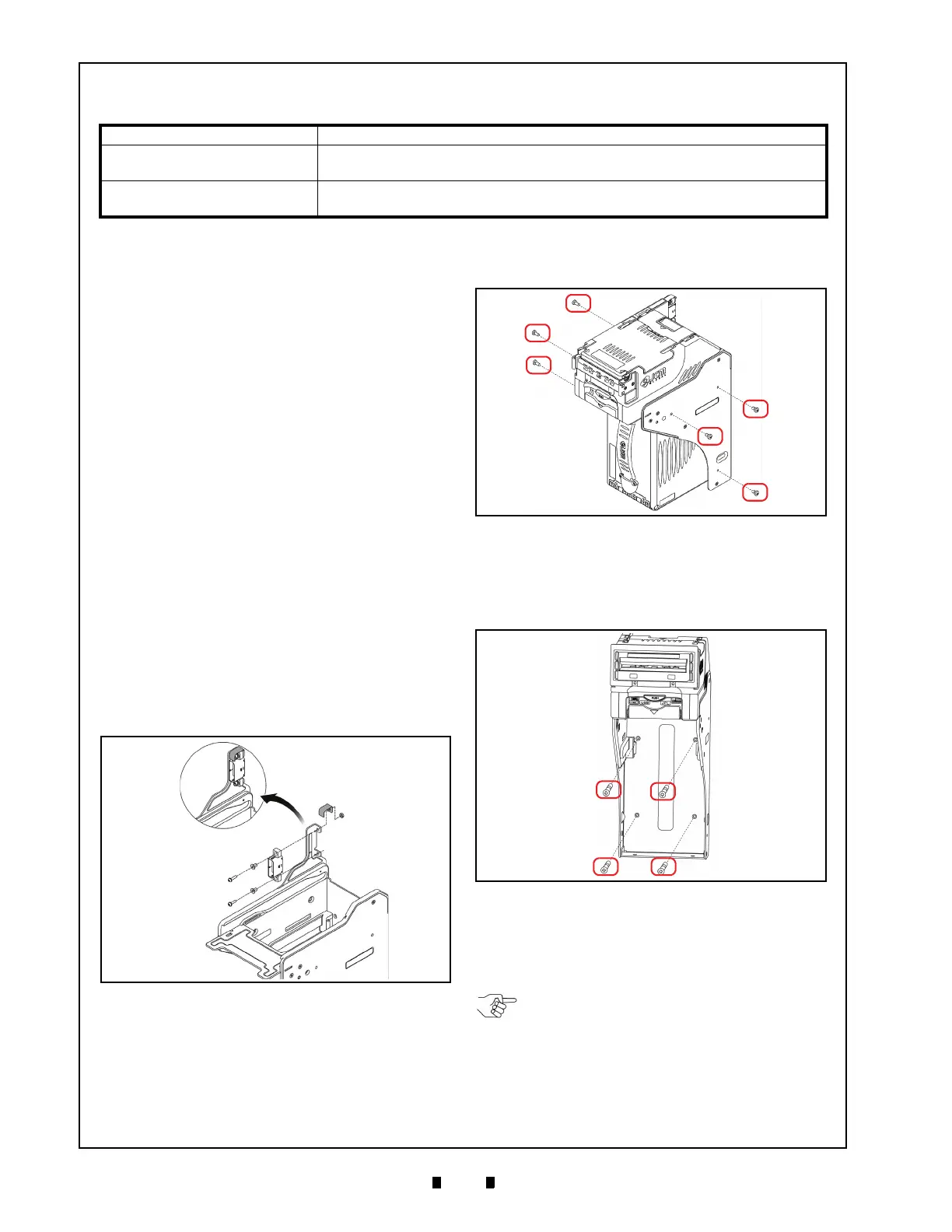

1. Install the Interface Harness to the Frame

Grounding Plate (FG PLT) (See Figure 4 a) using

the two (2) Floating Collars (See Figure 4 b), the

single (1) M2.6x12 W Washer (See Figure 4 c),

the single (1) M2.6x10 W Washer (See Figure 4

d) and the single (1) M2.6 Nylon N

ut (See

See Figure 4 e) to the Frame Assembly.

2. When a side mounting configuration is preferred,

bolt the left and right sid

e of the iVIZION™

Frame into its intended location using six (6) M4

Screws on both sides of the Frame (3 Screws on

each side as shown in Figure 4).

3. When an end mounting configuration is preferred,

remove the Cash

Box and bolt the rear end of the

iVIZION™ Frame into its intended location using

four (4) UNC6-32 Flat Head Screws from inside

the back end of the Frame as shown in Figure 5.

When installing the iVIZION™ Unit into the Host

Machine, refer to Figure 12 “iVIZION Instal

lation

and Maintenance Spac

e Requirements Dia

gram”

on page 9 of this document.

Table 4 iVIZION Structural Specifications

Weight Empty: Approximately 4.1kg (9.04 lbs)

Mounting:

Horiz

ontal (Maximum gradient limitation within 50 degrees; See Figure

12 on page 10)

Outside Dimensions:

Refer to “iVIZION Banknote Acceptor Unit Outside Dimensions” on

page 8 of this document.

3 INSTALLATION

Installation Procedure

Figure 3 Interface Harness Installation Location

Figure 4 M4 Screws Locations (Left/Right Side)

Figure 5

Flat Head Screws Locations (Rear Side)

NOTE: The length of the M4 Screws should

be selected in order not to puncture the

Plastic Surface of the iVIZION™ Frame

when aside mounting configuration is

preferred.

Loading...

Loading...