22.

NEEDLE-TO-HOOK

RELATION

1

* Set

the

needle to

hook

relation In

the

following way:

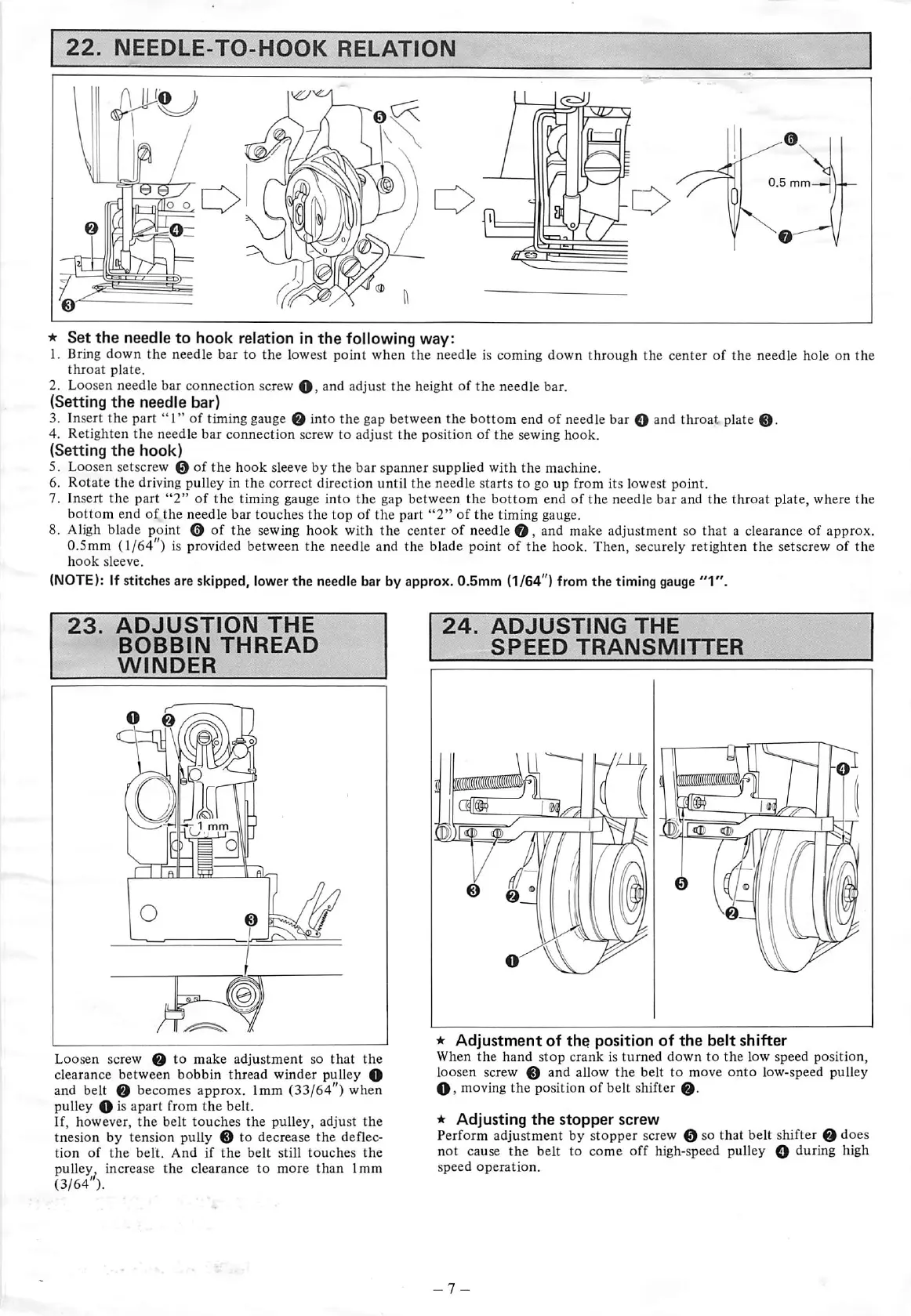

1. Bring

down

the

needle bar to

the

lowest

point

when

the needle is coming

down

through

the

center

of

the

needle hole on the

throat

plate.

2.

Loosen

needle

bar

connection

screw

0>

adjust

the

height

of

the

needle

bar.

(Setting

the

needle bar)

3. Insert the part

"1"

of timing gauge Q into the gap between the bottom end of needle bar 0 and throat plate

0.

4.

Retighten

the

needle

bar

connection

screw

to

adjust

the

position

of

the

sewing

hook.

(Setting

the

hook)

5. Loosen setscrew 0 of

the

hook sleeve by the bar spanner supplied with the machine.

6.

Rotate

the

driving pulley in

the

correct direction

until

the needle starts to go up from its lowest point.

7. Insert

the

part

"2"

of

the

timing gauge

into

the

gap between

the

bottom

end of

the

needle

bar

and the

throat

plate, where the

bottom

end of the needle

bar

touches

the

top

of the part

"2"

of

the

timing gauge.

8. Aligh blade point 0 of the

sewing

hook with the center of

needle©,

and make adjustment so that a clearance of approx.

0.5mm

(1/64") is

provided

between the

needle

and the blade point of the hook. Then,

securely

retighten the

setscrew

of the

hook

sleeve.

(NOTE):

If stitches are skipped, lowerthe needlebar by approx. 0.5mm (1/64") from the timinggauge

"1".

23.

ADJUSTION

THE

BOBBIN

THREAD

WINDER

H

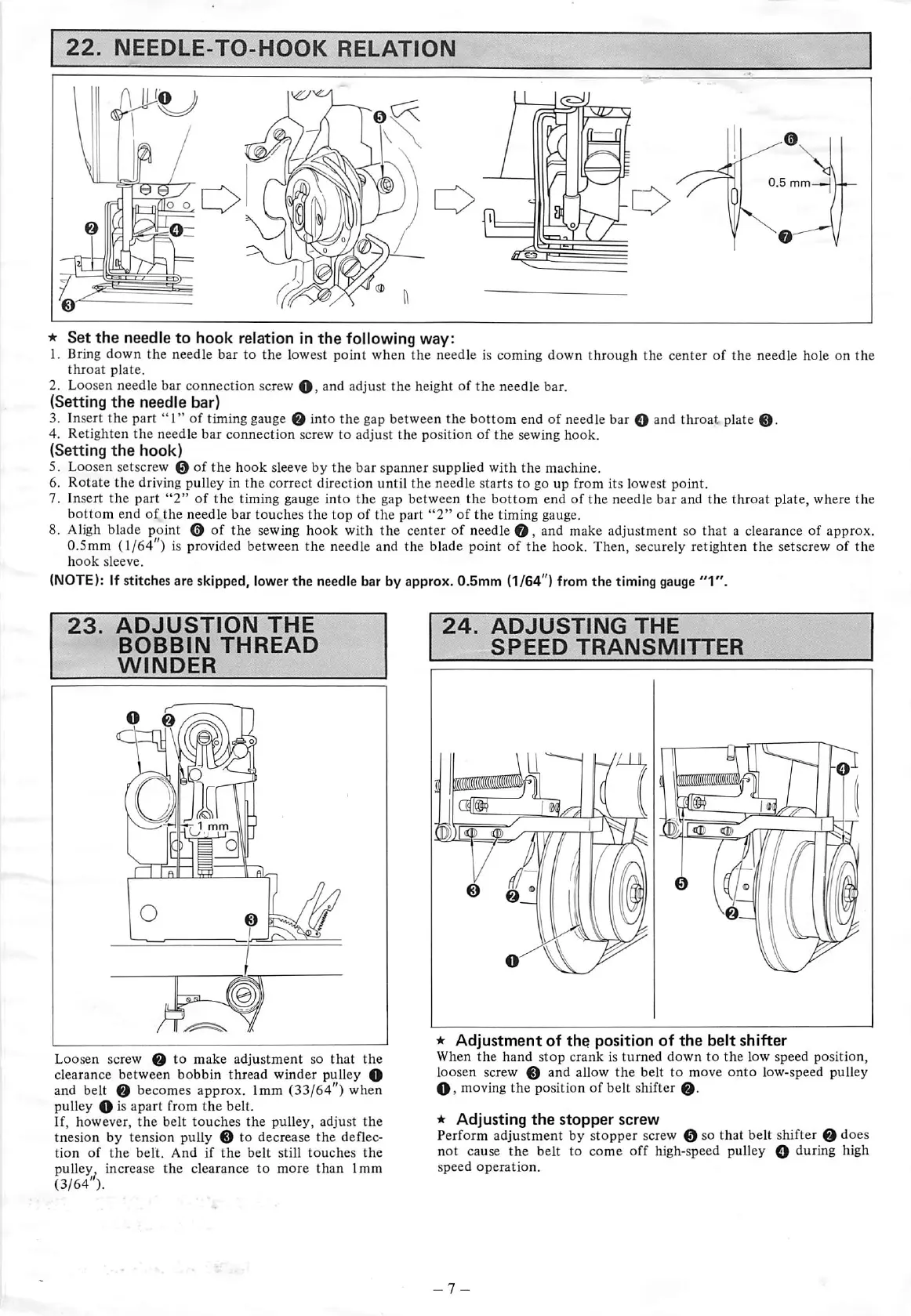

Loosen screw 0 to make

adjustment

so

that

the

clearance

between

bobbin

thread

winder

pulley

©

and belt © becomes approx. 1mm (33/64") when

pulley

O is

apart

from

the

belt.

If,

however,

the

belt

touches

the

pulley,

adjust

the

tnesion by tension pully 0 to decrease the deflec

tion

of

the

bell.

And

if

the

belt

still

touches

the

pulley,

increase

the

clearance

to

more

than

1mm

(3/64'^).

24.

ADJUSTING

THE

SPEED

TRANSMITTER

i

i

I

*

Adjustment

of

the

position

of

the

belt

shifter

When

the

hand

stop

crank

is

turned

down

to

the

low

speed

position,

loosen screw 0

and

allow

the

belt

to

move

onto

low-speed

pulley

0,

moving

the

position

of

belt

shifter

©.

*

Adjusting

the

stopper

screw

Perform adjustment by stopper screw 0 so

that

belt shifter 0 does

not

cause

the

belt

to

come

off

high-speed pulley © during high

speed

operation.

-7

-

From the library of: Superior Sewing Machine & Supply LLC

Loading...

Loading...