41.

AUTOMATIC

PRESSER

FOOT

LIFTER,

AK-II

(optional

attachment)

The automatic

presser

foot lifter

AK-11

is an optional attachment which is capableof lifting the presser foot and holdingit at the

heighest

position

for

60

seconds

after

thread

trimming

has

been

made.

I I

—I

*

Presser

foot

lifter

stroke

^ .. . 1.

Loosen

locknut O of the

coupler.

\ n * ~ — 2.

Lower

presser

foot stopper (A)0

fully

.—..

•—

J^i

cU

by

loosening

the

lock

nut.

' l' I 3.

Push

the

knee

switch

to

drive

the

sole-

-

f^l

''

adjust

the

stroke

of

the

presser

•(7 ^

rotating

plunger

@ on the

Knee

switch

—

•/

n\

solenoid;

the

stroke

is

n ^ ^ ^ \ \

increased

by

a

clockwise

turn

and

is

l L=

<=

c V /r^ 1

decreased

by

a

counterlockwise

turn.

Ml

J/^

(The

maximum

stroke

performed

by

the

^1

<=r-<5y

-=.

<=

<=

/^

\(^)

presser

foot

is

about

8

mm

(5/16")).

n(i

(W

^ 5.

Raise

stopper

(A)

until

it

hits

the oil

*

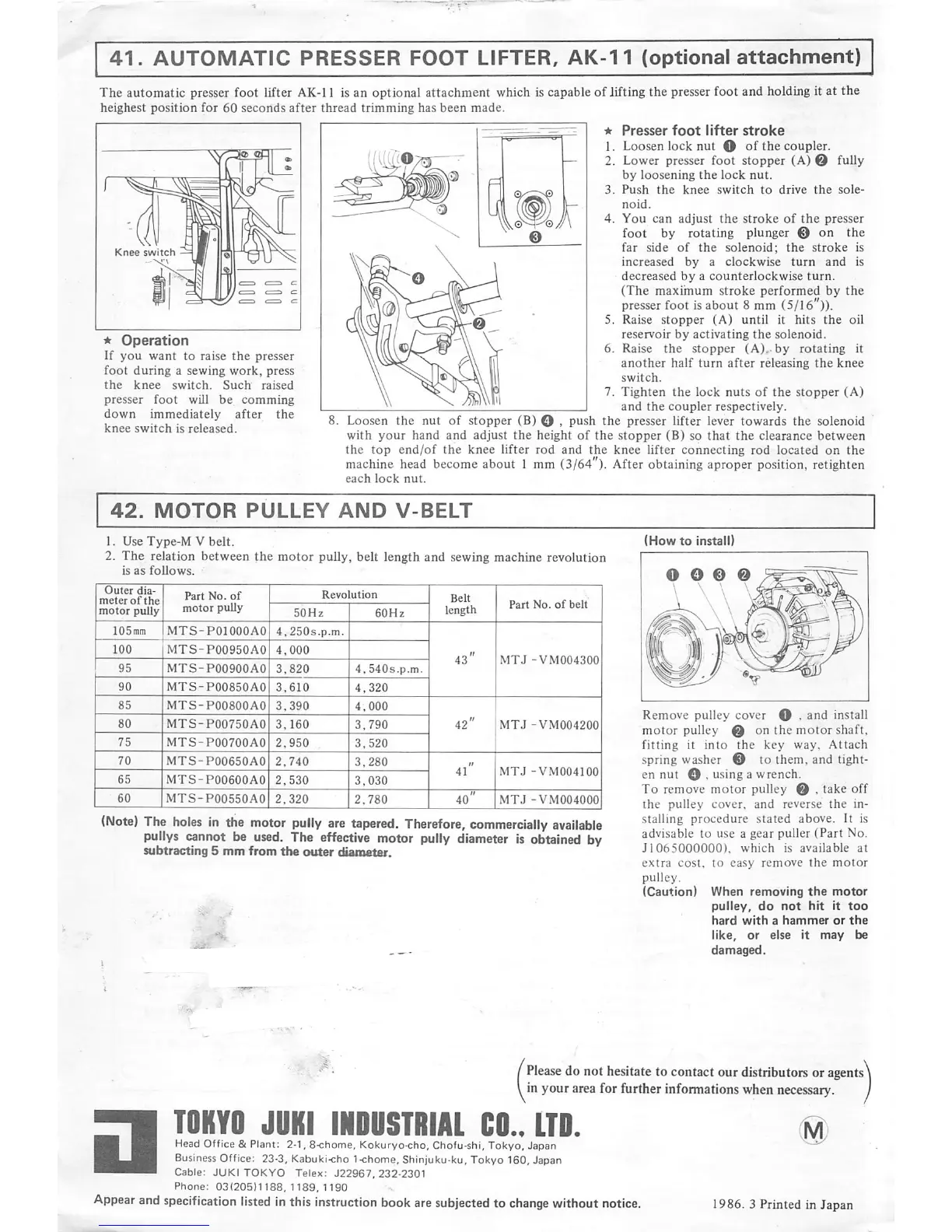

Operation

^[dLfM\

K ^

reservoir

by

activating

the

solenoid

If

.

\\

I

lU

W V o-

Raise

the

stopper

(A),

by

rotating

it

If

you

want

to

raise

the

presser

/ri\

rn »u u

ir..

f- i • »u i

r \ . • • ,

Nv

1

another

half

turn

after

releasing

the

knee

foot

during

a

sewing

work,

press

I®\S4\ 1

switch

the knee switch. Such

raised

\\

W i

t'

u*

'

♦!.

i i *

<•

*i.

♦

/•a\

. ^ .

\\

w\\p

7.

Tighten

the

lock

nuts

of

the

stopper

(A)

presser

foot

will

be

comming

\\

/^iWb

j

.v

i »• .

^ . j- » 1 ft th ' - ^ I and the

coupler

respectively.

own la e y a er e g loosen the nut of

stopper

(B) O >

push

the

presser

lifter

lever

towards

the

solenoid

nee

swi

c isre

ease

.

your

hand

and

adjust

the

height

of the

stopper

(B)

so

that the

clearance

between

the

top

end/of

the

knee

lifter

rod

and

the

knee

lifter

connecting

rod

located

on

the

machine

head

becomeabout 1 mm (3/64"). After obtaining aproper position, retighten

each

lock

nut.

*

Operation

If

you

want

to

raise

the

presser

foot

during

a

sewing

work,

press

the

knee

switch.

Such

raised

presser

foot

will be

comming

down

immediately

after

the

knee

switch

is

released.

42.

MOTOR

PULLEY

AND

V-BELT

1. Use

Type-M

V

belt.

2.

The

relation

between

the

motor

pully, belt length

and

sewing machine revolution

is

as

follows.

Outer

dia

meter

of

the

motor

pully,

Part

No.

of

motor

pully

Revolution

MTS-POIOOOAO

4,250s.p.m.l

MTS-P00950AO

4,000

3,820 I

4.540s.p.m.

MTS-P00850AO 3,610 4,320

MTS-P00800A0 3,390 4,000

MTS-POQ750A0

3.160 3,790

MTS-P00700A0 2,950 3.520

MTS-P00650A0

2,740

3,280

MTS-P00600A0

2,530

3,030

MTS-P00550A0

2.320 2,780

Part

No.

of

belt

MTJ

-VM004300

ImTJ

-VM004200

;MTJ

-VM004100

I

MTJ

-VM004000

(Note)

The

holes

in

the

motor

pully

are

tapered.

Therefore,

commercially

available

pullys

cannot

be

used.

The

effective

motor

pully

diameter

Is

obtained

by

subtracting

5

mm

from

tbe

outer

diameter.

-c-

f

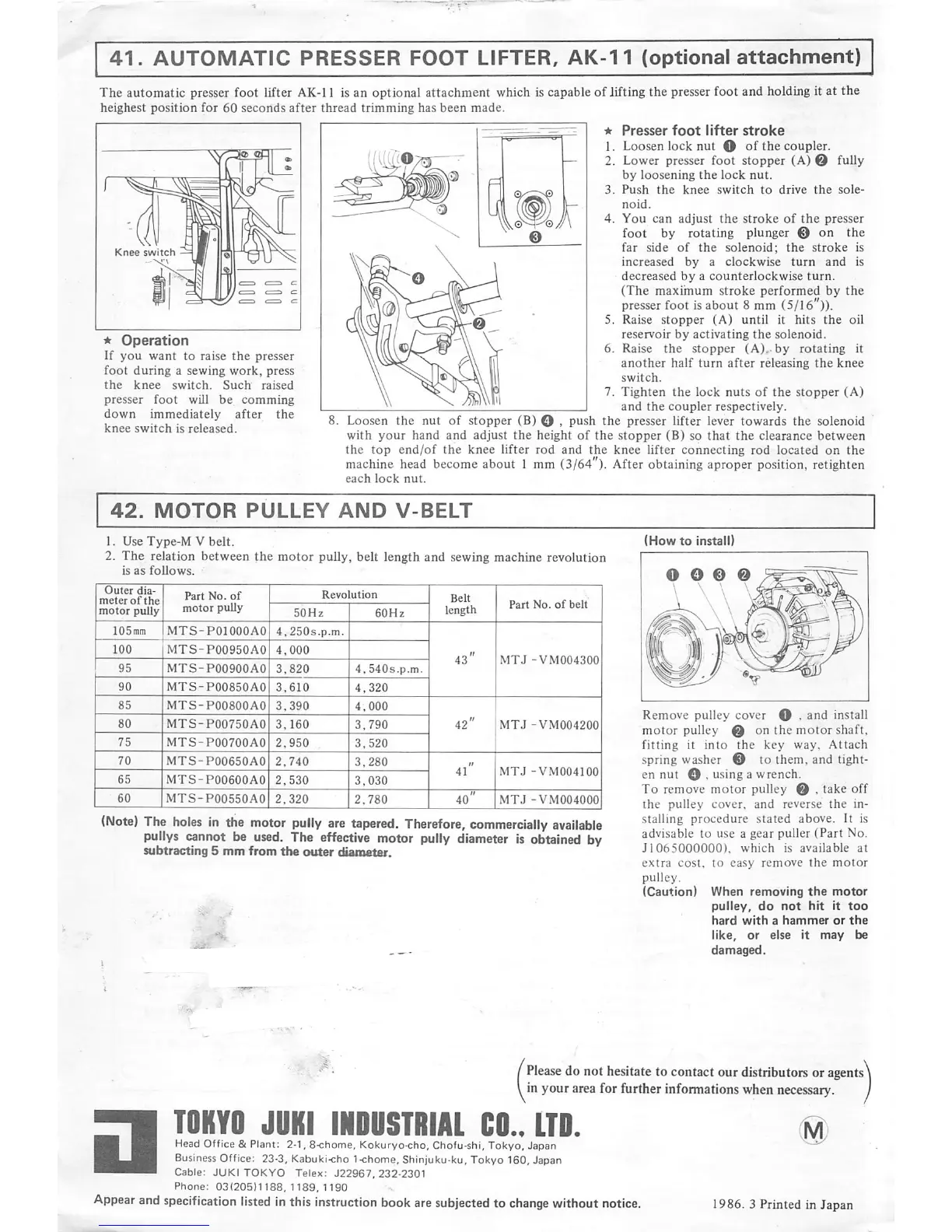

(How

to

Install)

O O 0 0

Remove pulley cover O . and install

motor

pulley 0 on the

motor

shaft,

fitting

it

into

the

key way.

Attach

spring washer 0 to them, and tight

en

nut

O , using a wrench.

To remove motor pulley 0 . take off

the pulley cover, and reverse

the

in

stalling

procedure

stated

above. It is

advisable to use a gear puller

(Part

No.

J1065000000),

which

is

available

at

extra

cost,

to

easy

remove

the

motor

pulley,

(Caution)

When

removing

the

motor

pulley,

do

not

hit

It

too

hard

with

a

hammer

or

the

like,

or

else

it

may

be

damaged.

Please

do not hesitate to contact our distributorsor

agents

inyour area for further informations when

necessary.

•

TOKYO

JUKI

IKOUSTRIAl

CO..

ITO.

Head Office & Plant: 2-1, 8-chome, Kokuryo-cho, Chofu-shi, Tokyo, Japan

Business Office: 23-3, Kabuki-cho 1<home, Shinjuku-ku. Tokyo 160, Japan

Cable:

JUKI

TOKYO

Telex:

J22967,

232-2301

Phone:

03(205)1188,1189,1190

Appear

and

specification

listed

in

this

instruction

book

are

subjected

to

change

without

notice.

1986.

3

Printed

in

Japan

Loading...

Loading...