26.

AMOUNT

OF

THREAD

TAKEN

UP

BY

THE

LEVER

Reduced

Increased

The

amount

of

thread

taken

up

by

the

thread

take-up

lever

must

be

reduced

when

light

weight

fabrics

are

sewn;

raise thread guide

O.

Inversely,

lower

thread

guide O

when

medium

or

heavy-weight

fabrics

are

sewn.

Note

that

the

G

specification

machine

has

a

special

thread

guide.

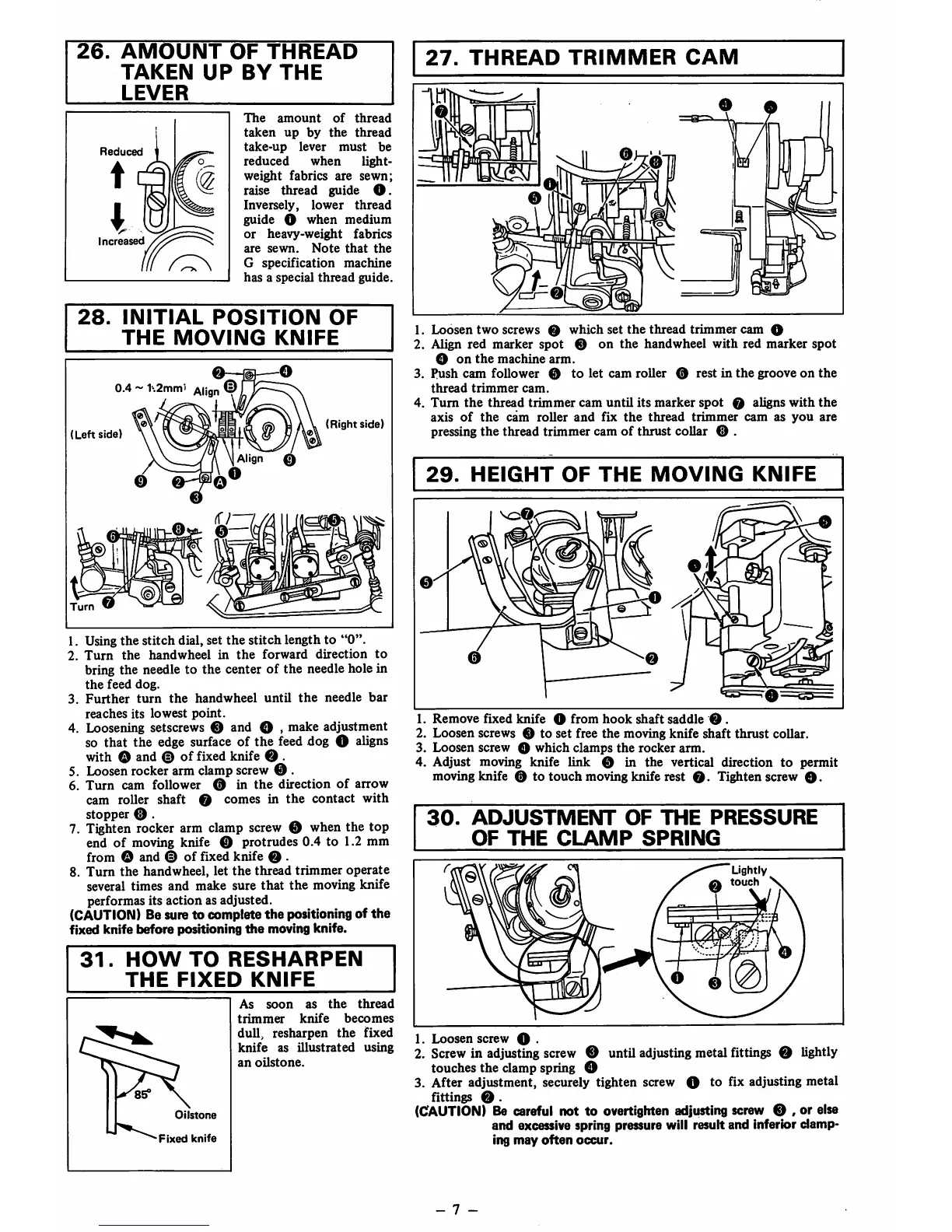

28.

INITIAL

POSITION

OF

THE

MOVING

KNIFE

0.4 ~

Aii„„

©

(Left

side)

Align 0

o

(Right

side)

1. Using

the

stitch

dial, set

the

stitch length to

"0".

2.

Turn

the

handwheel

in

the

forward

direction

to

bring

the

needle to

the

center

of

the

needle hole in

the

feed

dog.

3.

Further

turn

the

handwheel

until

the

needle

bar

reaches

its

lowest

point.

4. Loosening setscrews o and O , make adjustment

so that the edge surface of the feed dog O aligns

with O and 0 of fixed knife © .

5. Loosen rocker arm clamp screw 0 .

6.

Turn

cam follower 0 in

the

direction

of

arrow

cam roller shaft 0 comes in

the

contact with

stopper 0 .

7. Tighten rocker arm clamp screw 0 when the top

end

of

moving knife 0 protrudes

0.4

to 1.2 mm

from

O and ©

of

fixed

knife

0 .

8.

Turn

the

handwheel,

let

the

thread

trimmer

operate

several

times

and

make

sure

that

the

moving

knife

performas its

action

as adjusted.

(CAUTION) Be sure

to

complete

the

positioning of

the

fixed knife

before

positioning

the

moving knife.

31.

HOW

TO

RESHARPEN

THE

FIXED

KNIFE

Oilstone

Fixed

knife

As

soon

as

the

thread

trimmer

knife

becomes

dull, resharpen

the

fixed

knife

as

illustrated

using

an

oUstone.

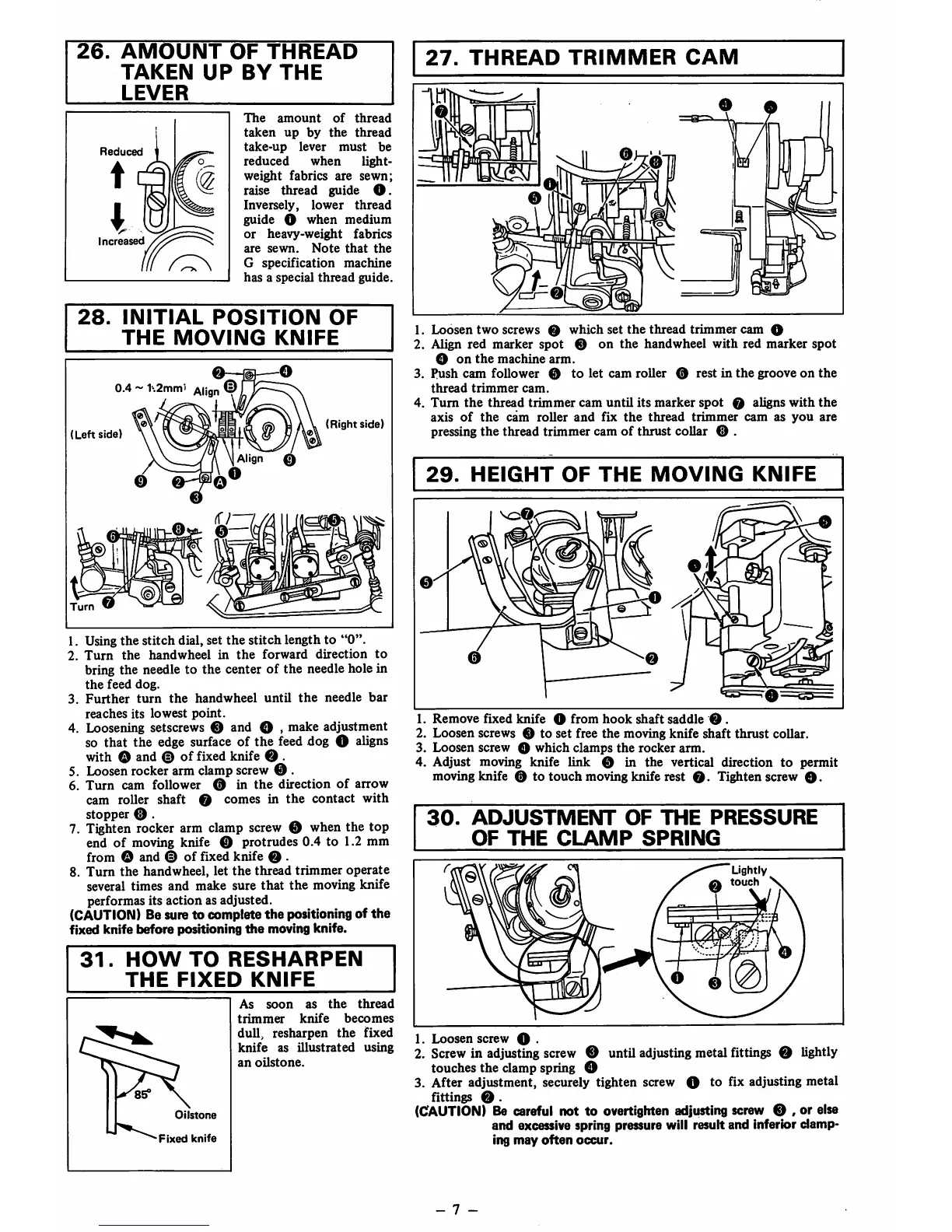

27.

THREAD

TRIMMER

CAM

1.

Loosen

two

screws

0

which

set

the

thread

trimmer

cam

O

2. Align

red

marker

spot

0

on

the

handwheel

with

red

marker

spot

O

on

the

machine

arm.

3.

Push

cam

follower 0

to

let

cam

roller

0 rest

in

the

groove

on

the

thread

trimmer

cam.

4.

Turn

the

thread

trimmer

cam

until

its

marker

spot

0 aligns

with

the

axis

of

the

cam

roller

and

fix

the

thread

trimmer

cam

as

you

are

pressing

the

thread trimmer cam

of

thrust collar 0 .

29.

HEIGHT

OF

THE

MOVING

KNIFE

1

^0r

✓WiSU/1

P

® \ \ ^

0

1.

Remove

ftxed

knife

O

from

hook

shaft

saddle

0.

2.

Loosen

screws 0

to

set

free

the

moving

knife

shaft

thrust

collar.

3.

Loosen

screw O

which

clamps

the

rocker

arm.

4. Adjust moving knife

link

0 in

the

vertical direction

to

permit

moving knife 0 to

touch

moving knife rest

0.

Tighten screw

0.

30.

ADJUSTMENT

OF

THE

PRESSURE

OF

THE

CLAMP

SPRING

Lightly

0

touch

1. Loosen screw O .

2. Screw in adjusting screw 0 until adjusting metal fittings 0 lightly

touches the clamp spring O

3. After adjustment, securely tighten screw O to fix adjusting metal

nttings

0 .

(CAUTION)

Be careful not to overtighten adjusting screw 0 , or else

and

excessive spring pressure will result and inferior

damp

ing

may

often

occur.

- 7 -

Loading...

Loading...