– 74 –

1. Thread breakage 1-1) Groove on the bobbin case stopper Grind the groove on the bobbin case stopper.

of the throat plate has scratches.

1-2)

The needle thread tension is too high.

Adjust the needle thread tension.

1-3) Needle-to-hook timing is not 3-A) The clearance provide between the Adjust the clearance provided between the hook and the

properly adjusted. hook and the bobbin case opener. bobbin case opener to 0.2 mm.

3-B)

The clearance provided between the

Adjust the clearance provided between the needle and the

needle and the blade point of the hook.

blade point of the hook to 0.05 mm.

3-C) The clearance provided between Check the clearance provide between the hook and the

the hook and the throat plate. throat plate.

3-D) Lift of the needle bar and the Adjust the lifting amount of the needle bar and the height

needle bar height. of the needle bar properly.

1-4)

Amount of oil in the hook is insufficient.

4-A) Amount of oil in the hook. Properly adjust the amount of oil in the hook.

1-5)

Operating range and pressure of the

5-A) Operating range and pressure of Properly adjust the thread take-up spring.

thread take-up spring are improper. the thread take-up spring.

1-6)

Blade point of the hook has scratches.

Grind the blade point of the hook.

1-7) Periphery of the needle hole in Grind the periphery of the needle hole in the feed plate.

the feed dog has scratches.

1-8) The machine head is not properly

Refer to the Instruction Manual, 11. How to pass the needle thread.

threaded.

1-9) The needle is not properly installed. 9-A) Orientation of the needle. Refer to the Instruction Manual, 8. How to set up the needle.

1-10)

The needle is bent or has a blunt point.

10-A) Needle Replace the needle with a new one.

1-11)

The presser foot is not properly installed. Install the presser foot while facing it in the correct direction.

1-12)The needle thread untwists. 12-A)If thread is likely to break especially when using a tetron thread:

1)

Minimize the needle thread tension and the thread take-up spring pressure as long as stitches are neatly finished.

2) Wind the thread round the needles to reduce the frequency of the trouble.

1-13)Idling stitches are produced.

1-14)A thread loop is not made with Use the thread guide equipped with a felt pad.

consistency when the blade point

of the hook clamps the needle thread.

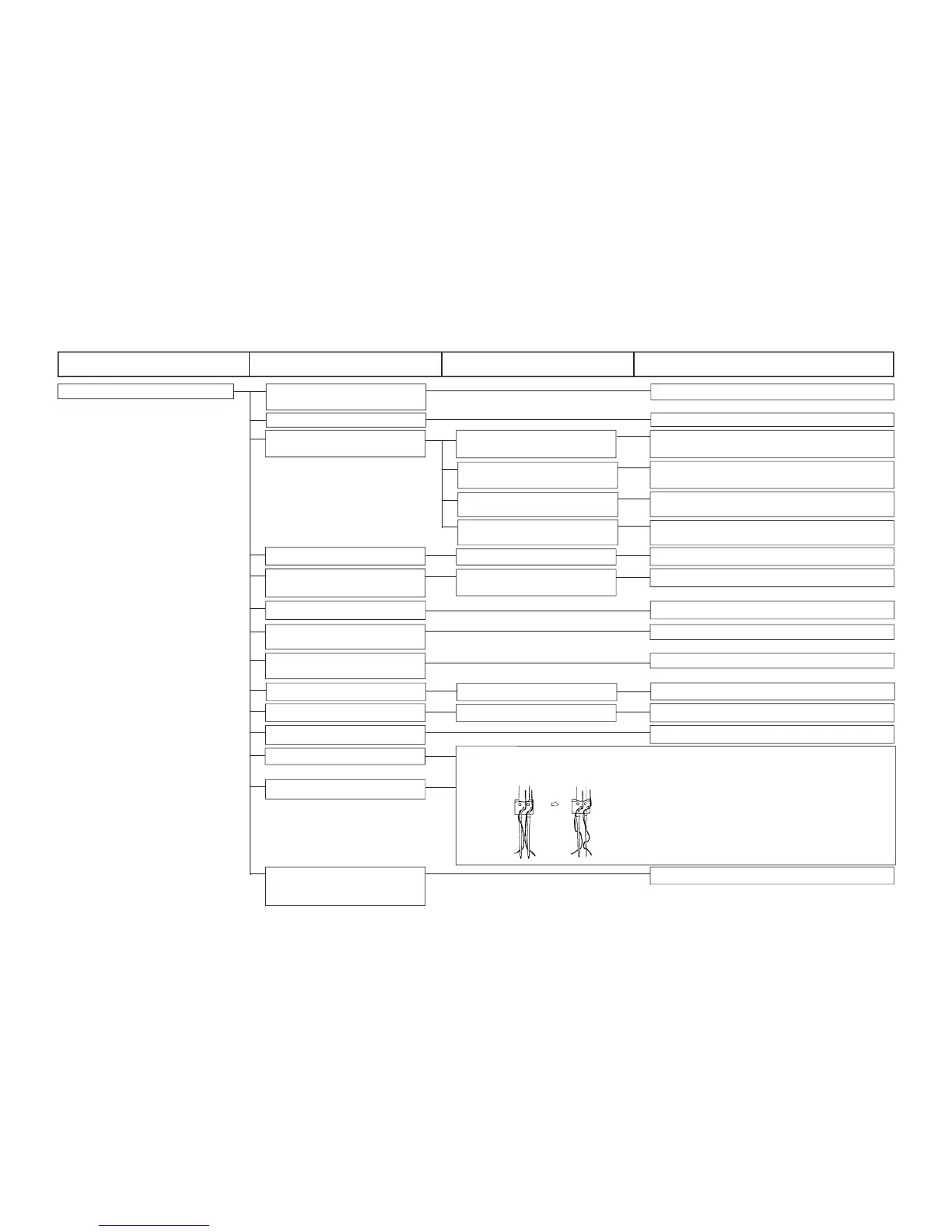

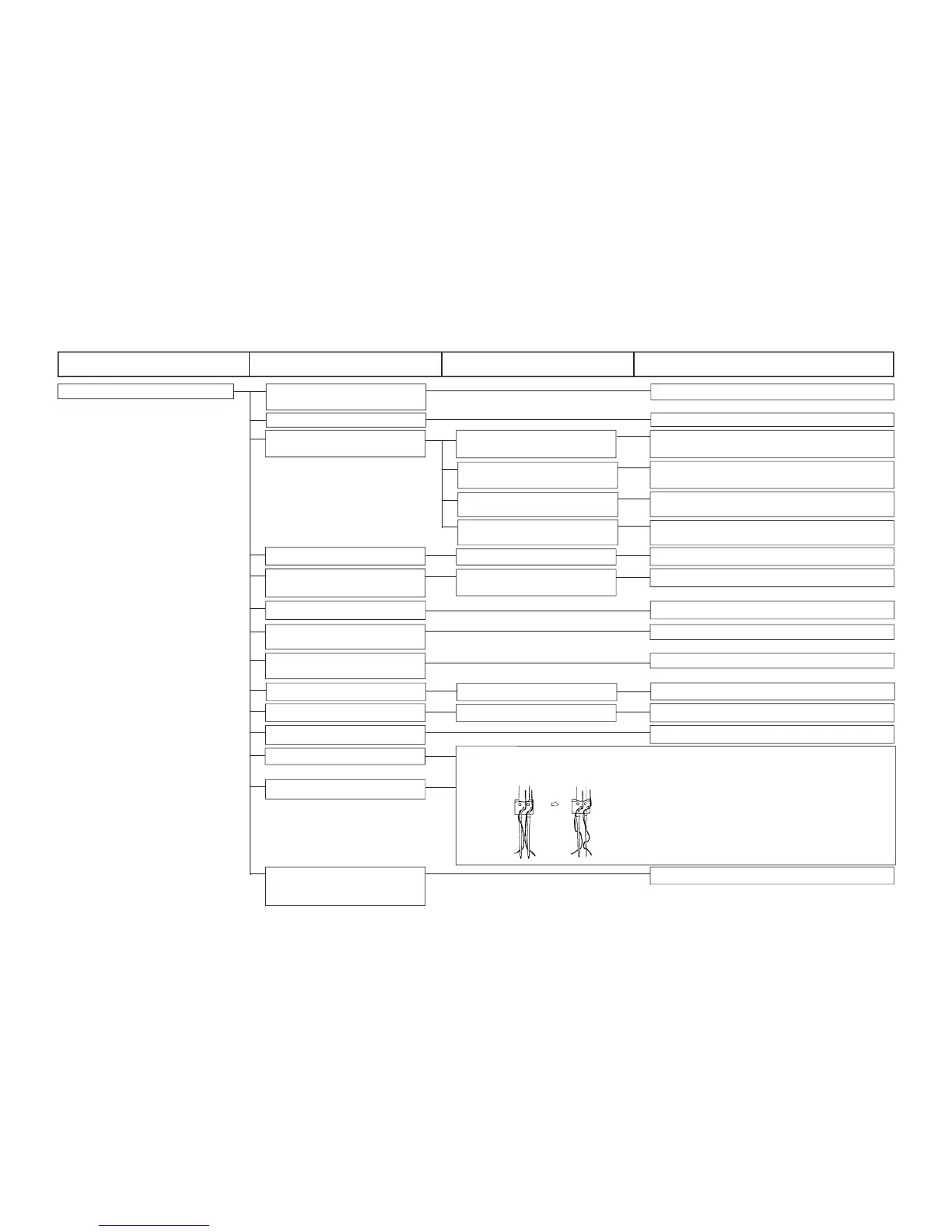

Trouble Case (1) Case (2) Check and Corrective measures

14. Troubles and corrective measures

Loading...

Loading...