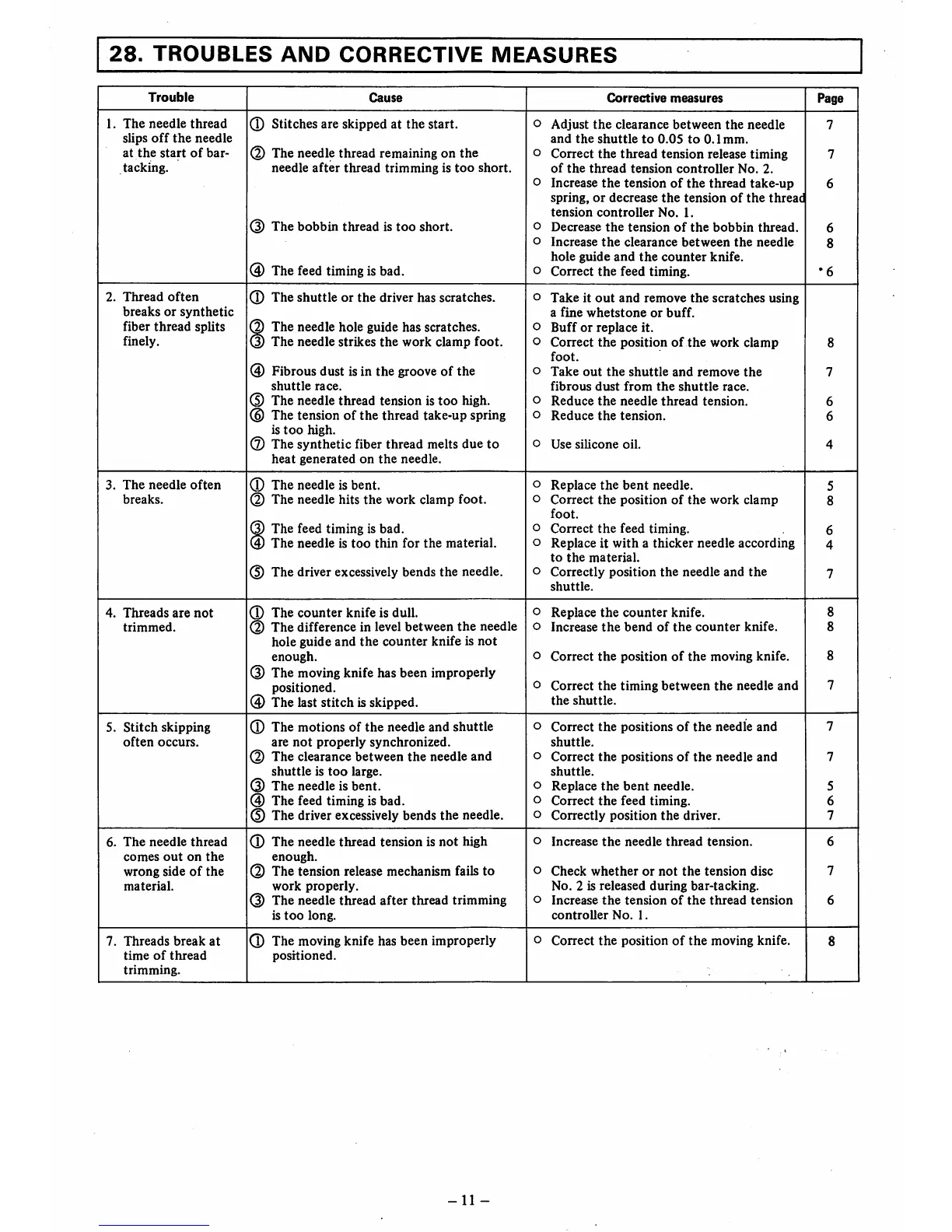

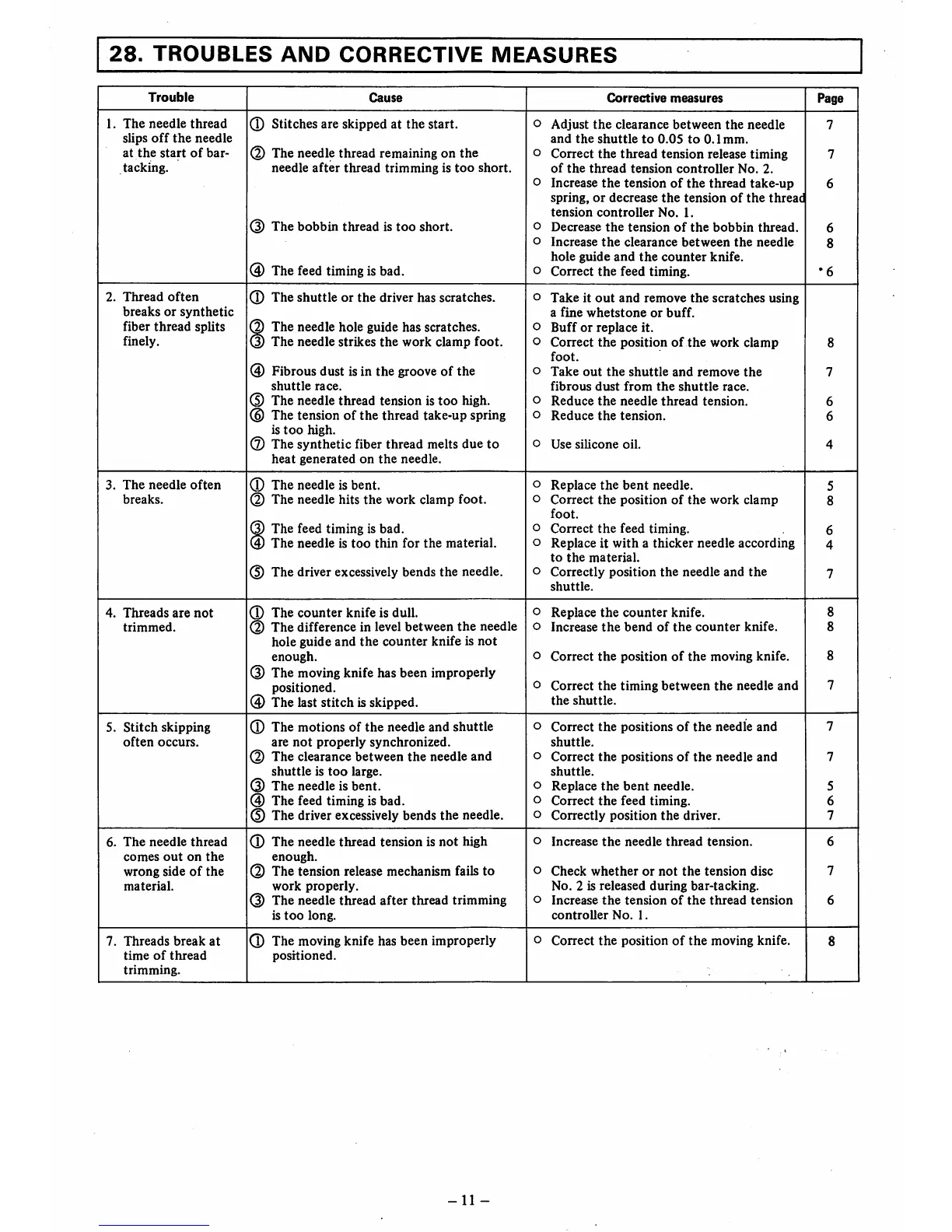

28.

TROUBLES

AND

CORRECTIVE

MEASURES

Trouble

Cause

Corrective

measures

Page

1.

The

needle

thread

slips

off

the

needle

at

the

start

of

bar-

tacking.

0 Stitches are skippedat the start.

0 The needlethread remainingon the

needle

after

thread

trimming

is

too

short.

0 The bobbin thread is too short.

0 The feedtimingis bad.

o

Adjust

the

clearance

between

the

needle

and

the

shuttle

to

0.05

to

0.1mm.

o

Correct

the

thread

tension

release

timing

of

the

thread

tension

controller

No.

2.

o

Increase

the

tension

of

the

thread

take-up

spring,

or

decrease

the

tension

of

the

thread

tension

controller

No.

1.

o

Decrease

the

tension

of

the

bobbin

thread,

o

Increase

the

clearance

between

the

needle

hole

guide

and

the

counter

knife,

o

Correct

the

feed

timing.

7

7

6

6

8

•6

2.

Thread

often

breaks

or

synthetic

fiber

thread

splits

finely.

0 The shuttle or the driver has scratches.

0 The needlehole guidehasscratches.

0 The needlestrikes the work clampfoot.

0 Fibrousdust isin the

groove

of the

shuttle

race.

0 The needle thread tension is too high.

0 The tension of the thread take-up spring

is

too

high.

0 Thesynthetic fiber thread melts due to

heat

generated

on

the

needle.

o

Take

it

out

and

remove

the

scratches

using

a

fine

whetstone

or

buff.

O

Buff

or

replace

it.

o

Correct

the

position

of

the

work

clamp

foot.

o

Take

out

the

shuttle

and

remove

the

fibrous

dust

from

the

shuttle

race.

o

Reduce

the

needle

thread

tension.

o

Reduce

the

tension.

O

Use

silicone

oil.

8

7

6

6

4

3.

The

needle

often

breaks.

0 The needle is bent.

0 The

needle

hitsthe work

clamp

foot.

0 The feed timingis bad.

0 The

needle

istoo thinforthe

material.

0 The driverexcessively bends the needle.

o

Replace

the

bent

needle,

o

Correct

the

position

of

the

work

clamp

foot.

o

Correct

the

feed

timing,

o

Replace

it

with

a

thicker

needle

according

to

the

material,

o

Correctly

position

the

needle

and

the

shuttle.

5

8

6

4

7

4.

Threads

are

not

trimmed.

0 The counter knife is dull.

0 The difference in levelbetween the needle

hole

guide

and

the

counter

knife is

not

enough.

0 The movingknife has been improperly

positioned.

0 Thelaststitch isskipped.

o

Replace

the

counter

knife,

o

Increase

the

bend

of

the

counter

knife.

o

Correct

the

position

of

the

moving

knife.

o

Correct

the

timing

between

the

needle

and

the

shuttle.

8

8

8

7

S.

Stitch

skipping

often

occurs.

0 The motions of the needle and shuttle

are

not

properly

synchronized.

0 The clearance between the needle and

shuttle

is

too

large.

0 The needle is bent.

0 The feed timing is bad.

0 The driver excessively bends the needle.

o

Correct

the

positions

of

the

needle

and

shuttle.

o

Correct

the

positions

of

the

needle

and

shuttle,

o

Replace

the

bent

needle,

o

Correct

the

feed

timing,

o

Correctly

position

the

driver.

7

7

5

7

6.

The

needle

thread

comes

out

on

the

wrong

side

of

the

material.

0 The needle thread tension is not high

enough.

0 The tension release mechanism failsto

work

properly.

0 The needle thread after thread trimming

is

too

long.

o

Increase

the

needle

thread

tension.

o

Check

whether

or

not

the

tension

disc

No.

2 is

released

during

bar-tacking,

o

Increase

the

tension

of

the

thread

tension

controller

No.

1.

6

7

6

7.

Threads

break

at

time

of

thread

trimming.

0 The movingknife has been improperly

positioned.

o

Correct

the

position

of

the

moving

knife.

8

-11-

Loading...

Loading...