17.

THREAD

TENSION

Short

\j

Increas^©

ncrease

Decrease

^

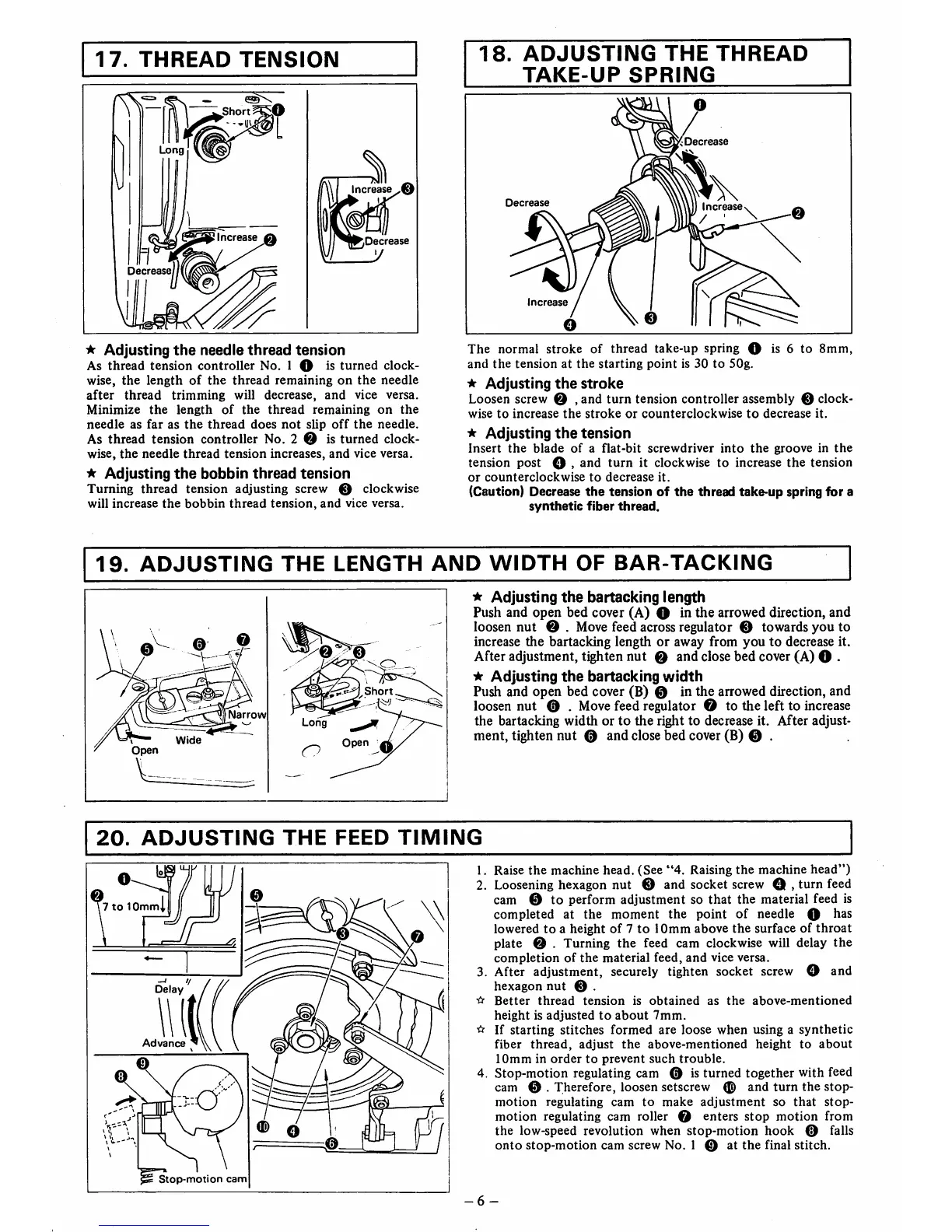

Adjusting

the

needle

thread

tension

As

thread

tension controller No. 1 O is

turned

clock

wise,

the

length

of

the

thread

remaining

on

the

needle

after

thread

trimming

will

decrease,

and

vice versa.

Minimize

the

length

of

the

thread

remaining

on

the

needle

as

far

as

the

thread

does

not

slip

off

the

needle.

As

thread

tension

controller

No. 2 0 is

turned

clock

wise,

the

needle

thread

tension

increases,

and

vice

versa.

*

Adjusting

the

bobbin

thread

tension

Turning

thread

tension

adjusting

screw

0

clockwise

will

increase

the

bobbin

thread

tension,

and

vice

versa.

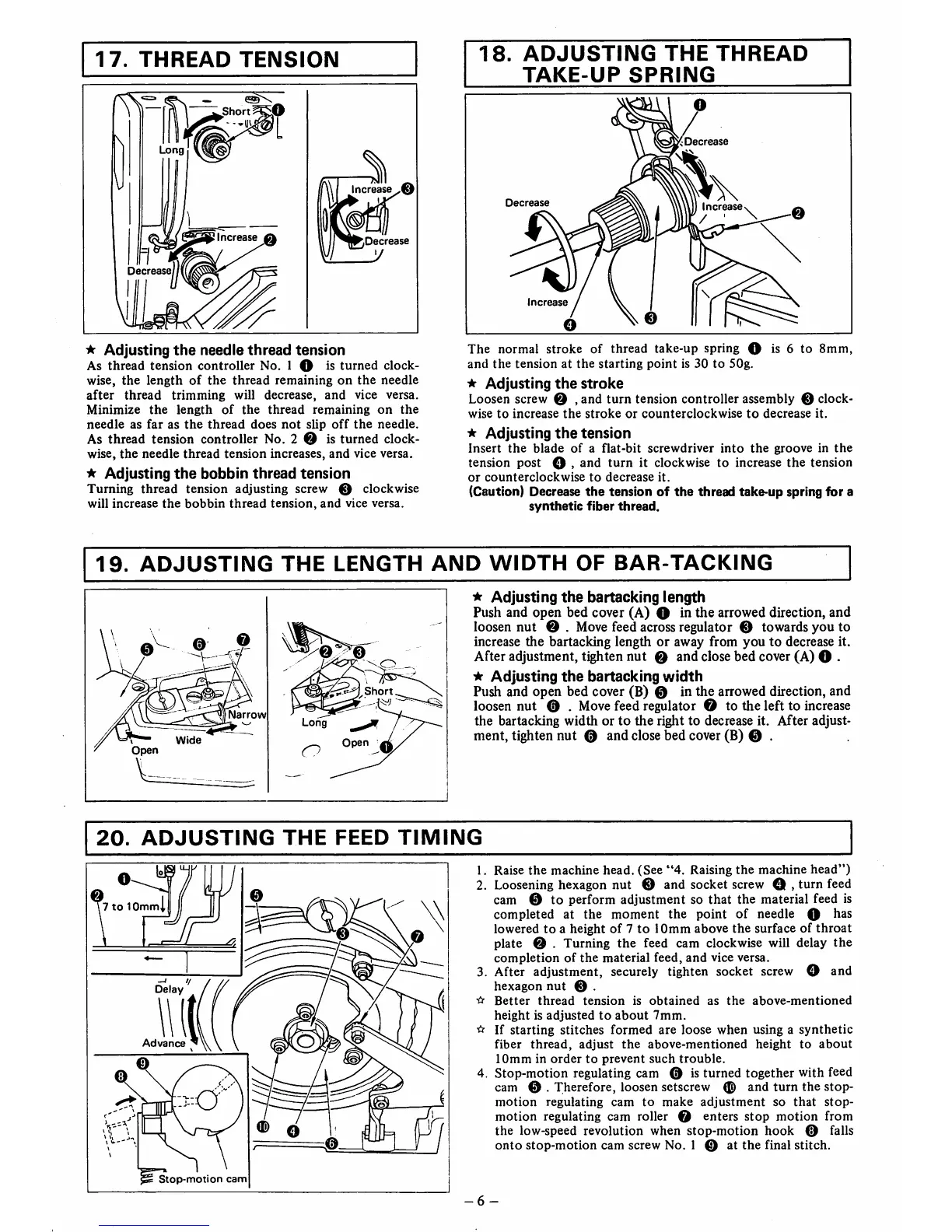

18.

ADJUSTING

THE

THREAD

TAKE-UP

SPRING

Decrease

Decrease

ncrease

Increase

The

normal

stroke

of

thread

take-up

spring O is 6 to

8mm,

and

the

tension

at

the

starting

point

is

30

to

50g.

ir

Adjusting

the

stroke

Loosen screw 0 , and

turn

tension controller assembly 0 clock

wise

to

increase

the

stroke

or

counterclockwise

to

decrease

it.

*

Adjusting

the

tension

Insert

the

blade

of

a

flat-bit

screwdriver

into

the

groove

in

the

tension post O , and

turn

it clockwise to increase

the

tension

or

counterclockwise

to

decrease

it.

(Caution) Decrease

the

tension of

the

thread take-up spring for a

synthetic

fiber

thread.

19.

ADJUSTING

THE

LENGTH

AND

WIDTH

OF

BAR-TACKING

!/0:^

Short

Narrow

Open

•

*

Adjusting

the

bartacking

length

Push and open bed cover (A) O in the arrowed direction, and

loosen nut 0 .

Move

feed acrossregulator 0 towardsyou to

increase

the

bartacking length or away from

you

to

decrease it.

After adjustment, tighten nut 0 and closebed cover (A) O .

-k

Adjusting

the

bartacking

width

Push and open bed cover (B) 0 in the arrowed direction, and

loosen nut 0 .

Move

feed regulator 0 to the left to increase

the bartacking width or

to

the right to decrease it. After adjust

ment, tighten nut 0 and close bed cover (B) 0 .

20.

ADJUSTING

THE

FEED

TIMING

Advance

Stop-motion

cam

1. Raise

the

machine

head.

(See

"4.

Raising

the

machine

head")

2. Loosening hexagon nut © and socket screw Q , turn feed

cam 0

to

perform adjustment so

that

the

material feed is

completed

at

the

moment

the

point

of

needle 0 has

lowered

to

a height

of

7

to

10mm

above

the

surface

of

throat

plate 0 . Turning

the

feed cam clockwise will delay

the

completion

of

the

material

feed,

and

vice versa.

3. After adjustment, securely tighten socket screw O and

hexagon

nut

0 .

Better

thread

tension

is

obtained

as

the

above-mentioned

height

is

adjusted

to

about

7mm.

•ir

If

starting

stitches

formed

are

loose

when

using

a

synthetic

fiber

thread,

adjust

the

above-mentioned

height

to

about

10mm

in

order

to

prevent

such

trouble.

4.

Stop-motion

regulating cam 0 is

turned

together

with

feed

cam 0 . Therefore, loosen setscrew 0 and

turn

the

stop-

motion

regulating

cam

to

make

adjustment

so

that

stop-

motion

regulating cam roller 0 enters

stop

motion

from

the

low-speed

revolution

when

stop-motion

hook

0 falls

onto

stop-motion

cam screw No. 1 0 at

the

final

stitch.

-6-

Loading...

Loading...