– 39 –

Adjustment Procedures Results of Improper Adjustment

1) Position of the counter knife and the clamp spring

1. Loosen setscrews 1 in the counter knife.

2. Make the edge of counter knife 3 come in contact with the

step difference of counter knife base 2.

3. Adjust the distance from the edge of counter knife base 2 to

the top end of counter knife to 3 dimension A.

4. Tighten setscrews 1 in the counter knife.

Position of the clamp spring

1. Loosen clamp spring setscrews 4.

2. Make the edge of clamp spring 5 come in contact with the

step difference of counter knife base 2.

3. Slide the clamp spring while making it come in contact with the

step difference of the counter knife base, and adjust the

distance to dimension B.

4. Tighten clamp spring setscrews 4.

For the details, refer to the list below.

(Caution) When the position of counter knife 3 and clamp

spring 5 is moved, re-adjust the position of counter knife

base 2 and the knife pressure.

List

When dimension A is larger

™ Length of bobbin thread clamp

is shortened and stitch skipping

occurs.

™ Setting/taking out bobbin cannot

be performed.

When dimensionA is smaller

™ Thread trimming failure will be

caused.

When dimesion B is larger

™ Bobbin thread clamp failure

occurs.

™ Stitch skipping at the start of

sewing will be caused.

When dimension B is smaller

™ It is difficult to clamp needle

thread and take out cloth, and

the trouble that bobbin thread

clamp is simultaneously

removed will be caused.

™ Clamp spring interferes with the

rear edge of moving knife and

deformation of clamp spring or

the like occurs.

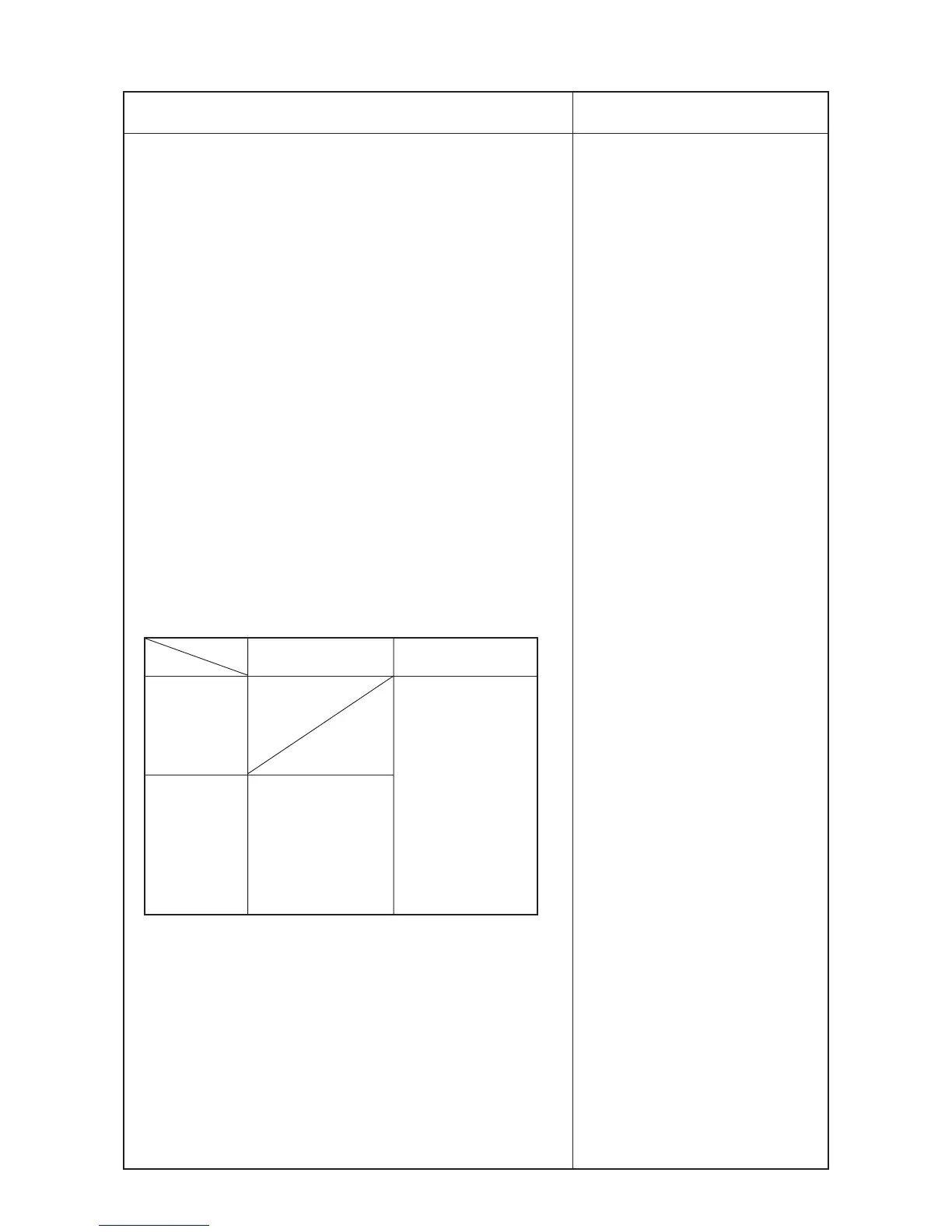

Position of right clamp

spring

Thickness of part A is 3.5

mm. Insert this part

between counter knife 3

and clamp spring 5, and

adjust clamp spring 5 so

that there is no

clearance.

LU-1510N-7

LU-1511N-7

LU-1560N-7

LU-1561N-7

Position of left clamp

spring

Thickness of part B is 4.5

mm. Insert this part

between counter knife 3

and clamp spring 5, and

adjust clamp spring 5 so

that there is no

clearance.

Loading...

Loading...