KD-A77

A/B/C/E/J/U

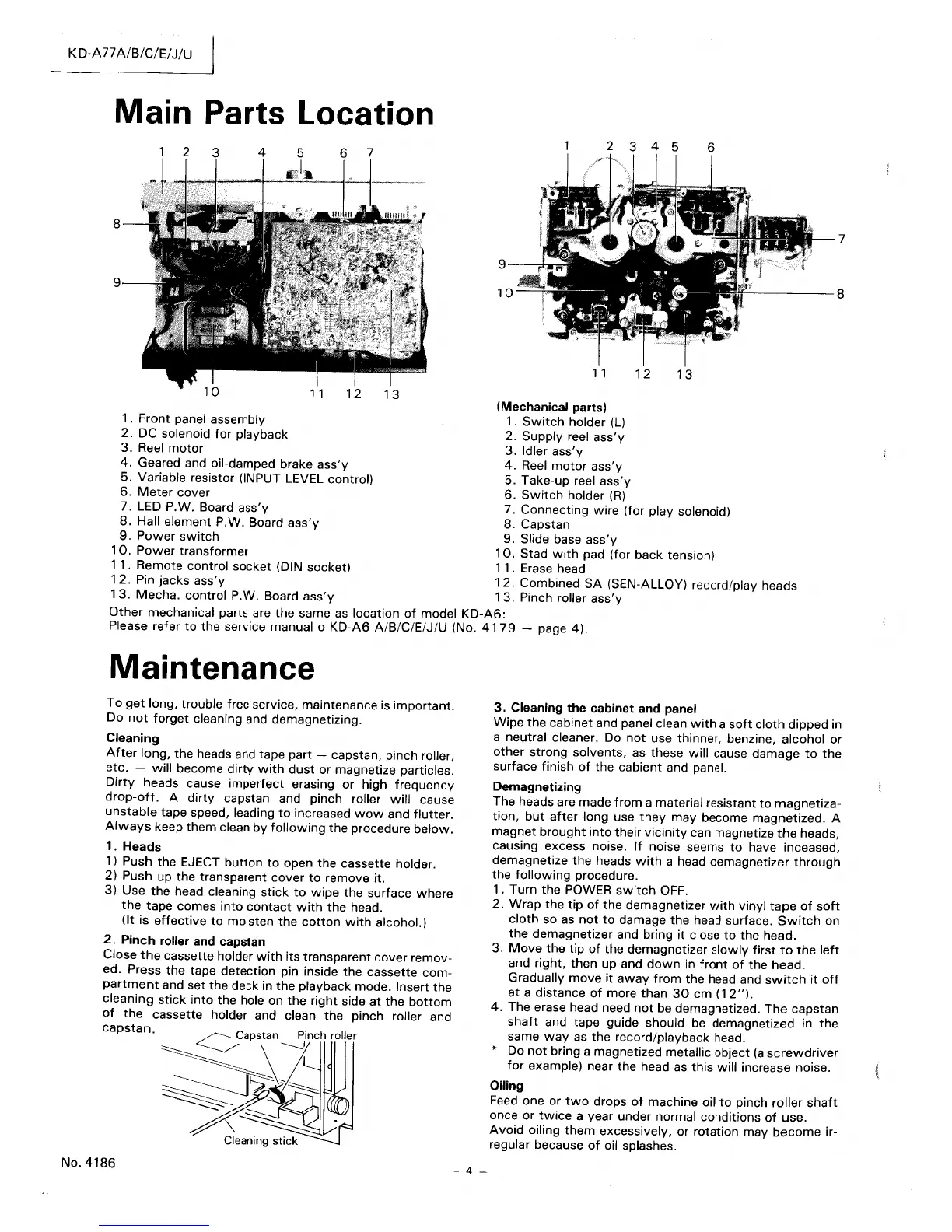

Main Parts Location

2 3 4 5 6

7

9

"--------

8

1 1

1 2 1 3

(Mechanical parts)

1.

Front

panel assembly

1.

Switch

holder (U

2.

DC solenoid

for

playback

2.

Supply

reel

ass'y

3.

Reel

motor

3.

Idler

ass'y

4.

Geared and oil-damped brake

ass'y

4.

Reel

motor

ass'y

5. Variable resistor (INPUT LEVEL control) 5. Take-up reel

ass'y

6.

Meter

cover

6.

Switch

holder

(R)

7.

LED P.W. Board

ass'y

7.

Connecting

wire

(for play solenoid)

8.

Hall

element

P.W. Board

ass'y

8.

Capstan

9.

Power

switch

9.

Slide base

ass'y

10.

Power

transformer

10.

Stad

with

pad (for

back

tension)

11.

Remote

control

socket

(DIN

socket)

11.

Erase head

12.

Pin

jacks

ass'y

12.

Combined

SA

(SEN-ALLOY) record/play heads

13.

Mecha.

control

P.W. Board

ass'y

13.

Pinch roller

ass'y

Other

mechanical parts are

the

same

as

location

of

model

KD-A6:

Please refer

to

the

service manual 0

KD-A6

A/B/C/E/J/U

(No.

4179

- page

4).

Maintenance

To

get

long, trouble-free service,

maintenance

is

important.

Do

not

forget

cleaning and

demagnetizing.

Cleaning

After

long,

the

heads and tape

part

- capstan,

pinch

roller,

etc.

-

will

become

dirty

with

dust

or

magnetize

particles.

Dirty

heads cause

imperfect

erasing

or

high

frequency

drop-off.

A

dirty

capstan and pinch roller

will

cause

unstable

tape speed, leading

to

increased

wow

and

flutter.

Always

keep

them

clean

by

following

the

procedure

below.

1.

Heads

1)

Push the EJECT

button

to

open

the

cassette

holder.

2)

Push

up

the

transparent

cover

to

remove

it.

3)

Use

the

head cleaning

stick

to

wipe

the

surface

where

the

tape

comes

into

contact

with

the

head.

(it

is

effective

to

moisten

the

cotton

with

alcohol.)

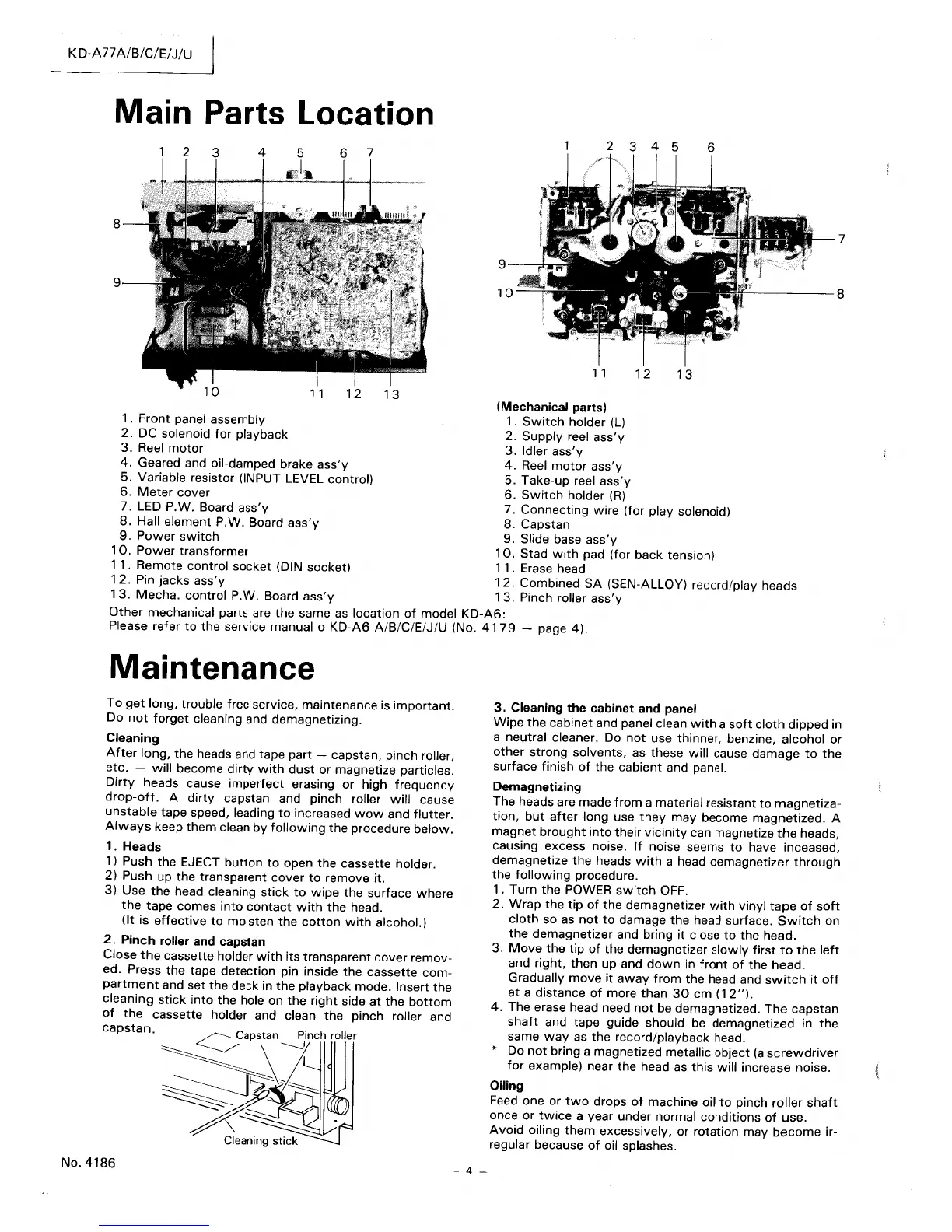

2.

Pinch roller and capstan

Close

the

cassette

holder

with

its

transparent

cover

remov-

ed. Press

the

tape

detection

pin inside

the

cassette

com-

partment

and

set

the

deck

in

the

playback

mode.

Insert

the

cleaning

stick

into

the

hole on

the

right

side

at

the

bottom

of

the

cassette

holder and clean

the

pinch roller and

oop"an.

~~:,"'h

"",,

~.~

Cleaning stick

No.

4186

- 4 -

3.

Cleaning the cabinet and panel

Wipe

the

cabinet

and panel clean

with

a

soft

cloth

dipped in

a neutral cleaner. Do

not

use thinner, benzine,

alcohol

or

other

strong

solvents,

as these

will

cause

damage

to

the

surface

finish

of

the

cabient

and panel.

Demagnetizing

The heads are made

from

a material resistant

to

magnetiza-

tion,

but

after

long use

they

may

become

magnetized.

A

magnet

brought

into

their

vicinity

can magnetize

the

heads,

causing excess noise.

If

noise seems

to

have inceased,

demagnetize

the

heads

with

a head

demagnetizer

through

the

following

procedure.

1.

Turn

the

POWER

switch

OFF.

2.

Wrap

the

tip

of

the

demagnetizer

with

vinyl

tape

of

soft

cloth

so as

not

to

damage

the

head surface.

Switch

on

the

demagnetizer

and bring

it

close

to

the

head.

3.

Move

the

tip

of

the

demagnetizer

slowly

first

to

the

left

and

right,

then

up and

down

in

front

of

the

head.

Gradually

move

it

away

from

the

head and

switch

it

off

at

a

distance

of

more

than

30

cm

(1

2").

4.

The

erase head need

not

be demagnetized.

The

capstan

shaft

and

tape

guide should be demagnetized in

the

same

way

as

the

record/playback

head.

* Do

not

bring a magnetized metallic

object

(a

screwdriver

for

example) near

the

head as

this

will

increase noise.

Oiling

Feed one or

two

drops

of

machine oil

to

pinch

roller

shaft

once

or

twice

a year

under

normal

conditions

of

use.

Avoid

oiling

them

excessively, or

rotation

may

become

ir-

regular because

of

oil splashes.

Loading...

Loading...