STARTER MOTOR INSPECITION

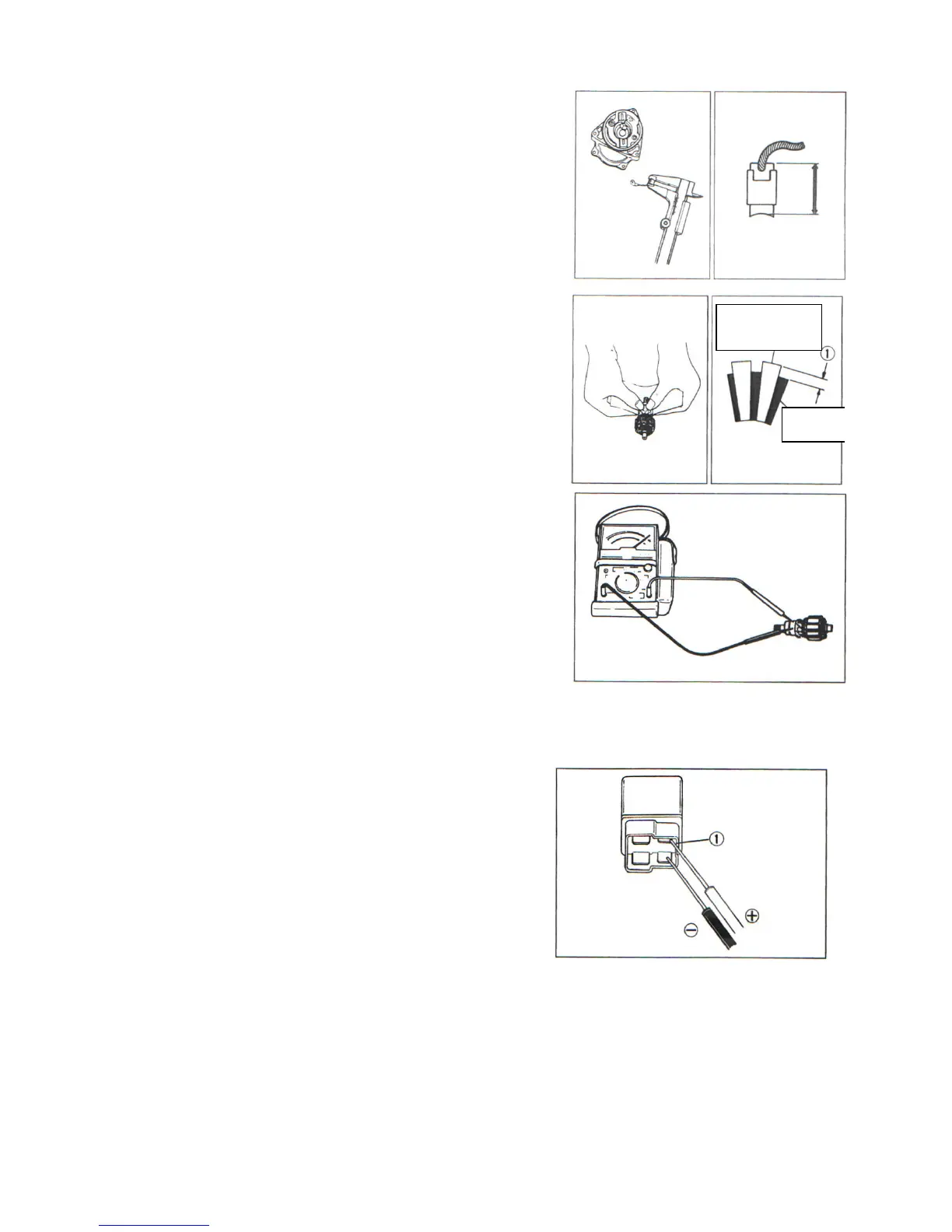

CARBON BRUSHES

When the brushes are worn, the motor will be unable to produce

sufficient torque, and the engine will be difficult to turn over. To

prevent the , periodically inspect the length of the brushes and replace

them when they are too short or chipping.

Service limit:

::

:3.5mm(0.14in)

Commutator

If the commutator surface is dirty, starting performance will decrease.

Polish the commutator with #400 or similar fine emery paper when it

is dirty.

Service limit:

::

:0.2mm(0.008in)

Armature coil

using the pocket tester, check the coil for open and ground by

plcing probe pins on each commutator segment and rotor core and on

any two segments at various places. With the brushes lifted off the

commutator surface. If the coil is found to be open-circuited or

grounded, replace the armatrue.

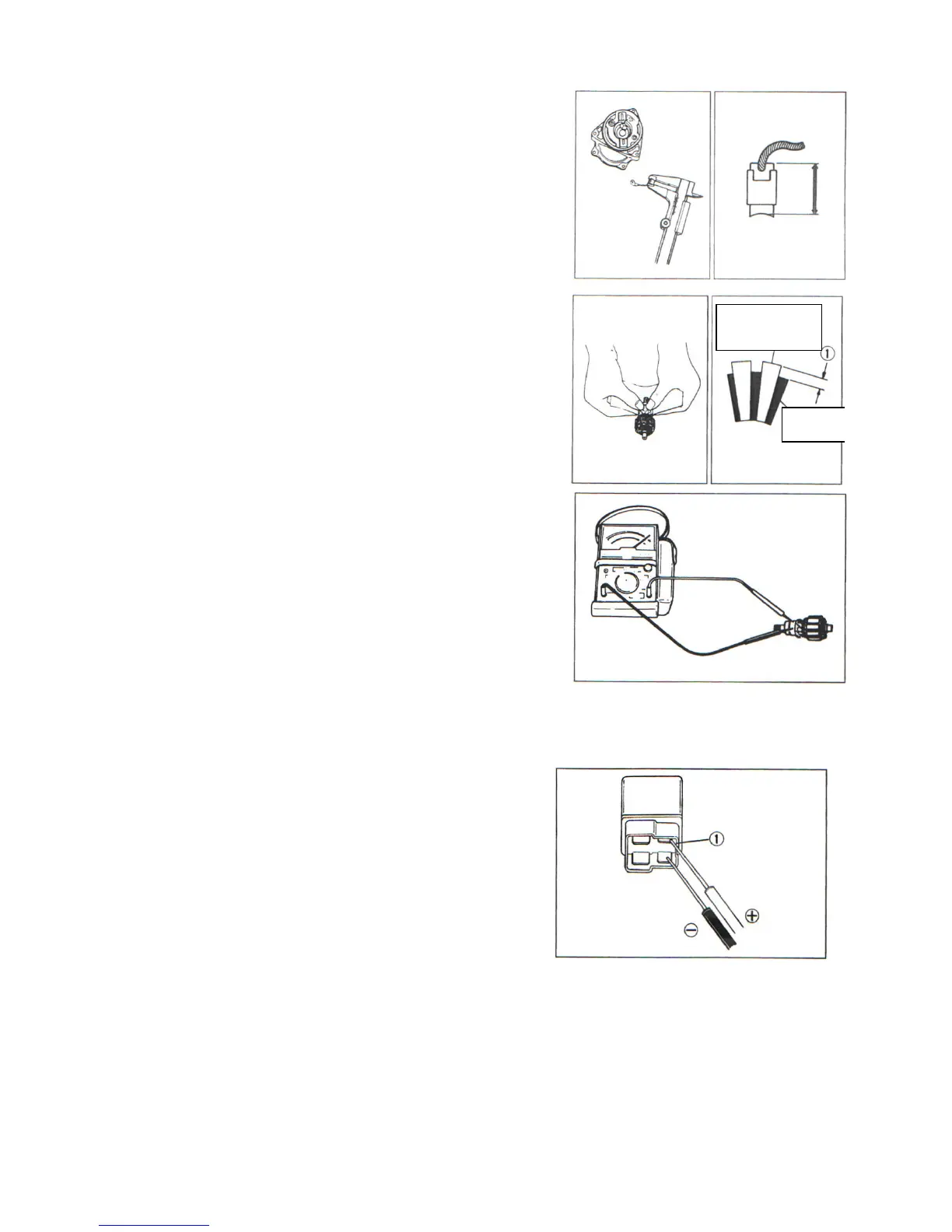

Starter relay inspection

Disconnect lead wire (R/W) of the starter motor. Turn on the

igniton switch and squeeze the front or rear brake lever, then

inspect the continuity between the Red and Red/White lead wires

at the starter relay when pushing the starter button.

If the starter relay is in sound condition, continuity is found.

● Disconnect the starter relay lead wire couple. Check the coil for

“open”, “ground” and ohic resistance. The coil is in good condition,

if the resistance is as follows:

STANDARD RESTANCE::80-150Q

Segment

Mica

Loading...

Loading...