25

This is a proprietary document of Kirloskar Brothers Limited, Kirloskarvadi-416308, Dist-Sangli (India)

ISSUE DATE: 17.09.2010 LAST REV. DATE:

STOPPING

Before stopping the pump; close the gate valve. This will prevent water hammer on the check valve.

STUFFING BOXES (only for gland packed pump)

Do not tighten the glands excessively. A slight dripping of water from the stuffing boxes when pump

is running keeps packing in good condition.

CASING RINGS

Casing rings are fitted in the casing to reduce the quantity of water leaking back from the high

pressure side to the suction side. These casing rings are fitted to maintain a small clearance and

depend on the water in the pump for lubrication. When the rings are worn out, the clearance becomes

greater and more water passes back into the suction side. The rings must be replaced from time to

time to restore the pump efficiency to its normal value.

SPARE PARTS

A set of ball bearings, a set of casing rings and a set of gland packing rings / mechanical seal must

always be kept at hand to ensure uninterrupted service from the pump. While ordering for spare parts,

always give type, size and serial number of the pump as stamped on the number plate.

PUMP TROUBLE

When investigating trouble with Kirloskar pumps, always remember that pumps have been tested at

the factory and are mechanically correct when sent out. Discounting the possibility of damage during

transit, most of the trouble in the field is due to faulty installation. Investigation shows that the

majority of troubles with centrifugal pumps result from faulty conditions on the suction side.

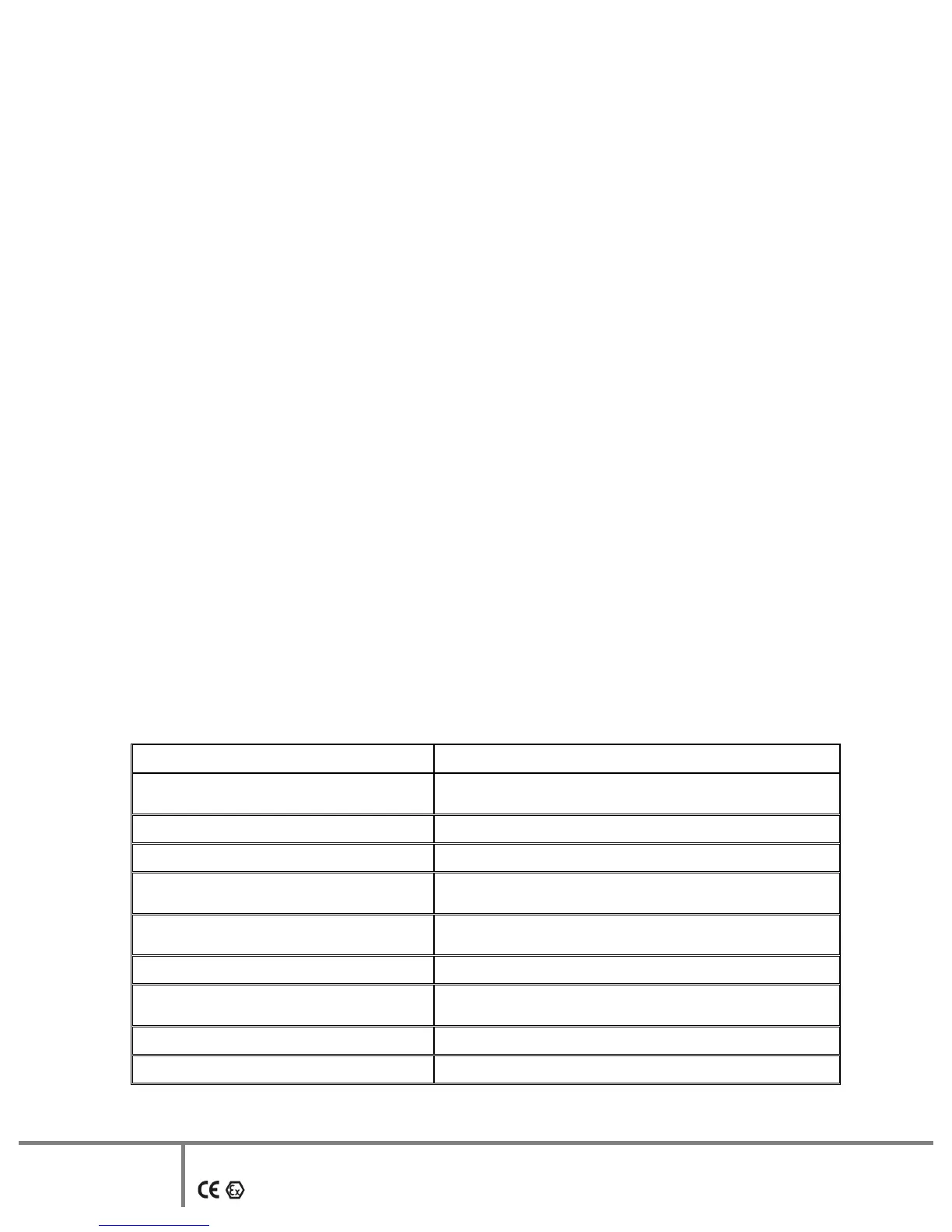

BREAK DOWN-CAUSE-CHECK POINTS

In case of breakdown we recommend the location of the fault by using the following table.

BREAKDOWN CHECK POINTS

Pump does not deliver 1 7 8 9 10 11 12 14 15 17 18 19 23 25 26 56 57 58

Pump delivers at reduced capacity

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 17 18 19 20 21 22

56 57 58

Delivery performance deteriorates 1 3 7 9 10 11 12 13 14 19 20 21 22 23 24 53 57 62

Pump delivers too much 16 56 57 58

Delivery is interrupted

1 3 6 7 8 9 10 11 12 13 14 15 16 19 22 23 25 26 56 57

58 62

After stopping pump runs in reverse

direction

52

Very noisy 1 2 5 6 7 8 11 12 13 15 19 20 22 54 55 56 57 62

Unsteady running of pump

19 20 22 31 32 33 35 36 37 38 39 40 43 44 47 48 49 50

51 54 55 58

Stuffing box leaks excessively 24 27 28 29 30 31 47 48 49 53

Fumes from stuffing box 22 23 24 25 26 27 28 29 30 41 42 43

Loading...

Loading...