32

WARNING: This saw was adjusted for accuracy at the factory. During shipping the

components may have been moved out of alignment. In addition, usage and time will

necessitate adjustments to be made.

WARNING

To prevent personal injury:

● Always disconnect plug from the power source when making any adjustments.

● This adjustment must be correct or accurate cuts can not be made. Also inaccurate adjustment

can result serious personal injury.

32

1

2

ADJUSTMENT INSTRUCTIONS

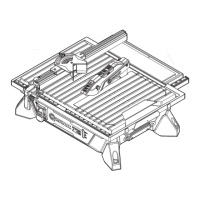

ADJUSTING THE FLOW OF WATER ON THE

PUMP (FIG. 31)

● Fill the water pan with clean water as

described below.

● Locate the “Max/Min” water ow selector (1)

on the pump. For best performance, set the

ow to “Max” to control the ow of water over

the wheel.

● The pump turns on when the motor is

turned on. Let the cutting wheel build up to

full speed and wait for the wheel to get wet

before moving the tile into the wheel.

NOTE: The ow of water can also be adjusted

using the external water volume control. See

page 37 for instructions.

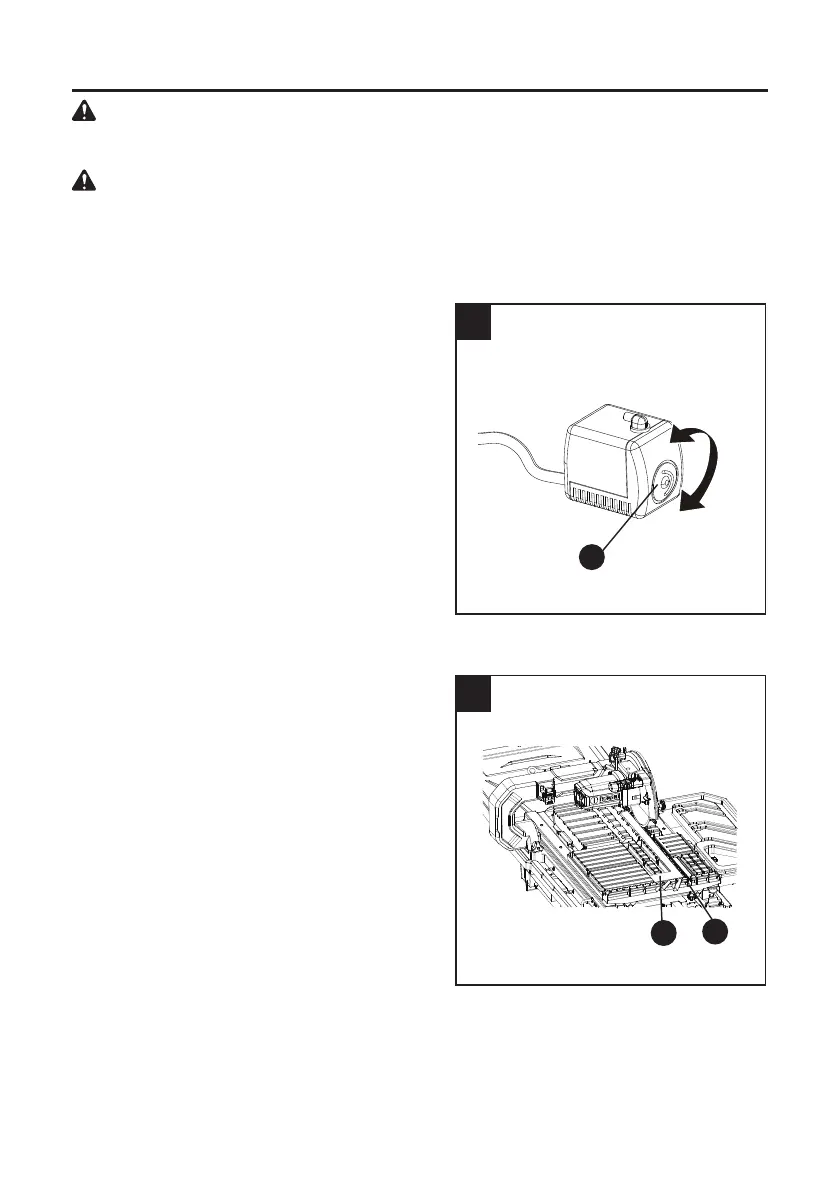

SQUARING THE CUTTING WHEEL

(FIG. 32, 33, 34)

Checking the cutting wheel alignment (Fig. 32)

● Place a 90° framing square (1) at on the

sliding table surface with one end against the

sliding T-fence extension.

● Push the sliding table along the cutting

wheel to determine if the groove along the

90° framing square is consistently ush

against the wheel throughout the length of

the stroke.

● If the groove is not consistent, see the next

steps.

31

1

MAX

MIN

Max

Min

Loading...

Loading...