TP-6323 3/0630 Section 3 Scheduled Maintenance

3.7.4 Pressure Cap

Closed heat exchanger systems utilize a pressure cap

to raise the boiling point of the coolant, enabling higher

operating temperatures. If the cap leaks, replace it with

a cap of the same rating. Find the pressure cap rating in

Figure 3-6.

3.7.5 Seawater Pump

The belt-driven seawater pump is located on the engine

end of the generator set. Check and change the

seawater pump impeller at the interval specified in the

service schedule. Follow the instructions included with

the impeller kit. If the instructions are not included with

the kit, use the following procedure:

Impeller Inspection and Replacement Procedure:

1. Close the seacock.

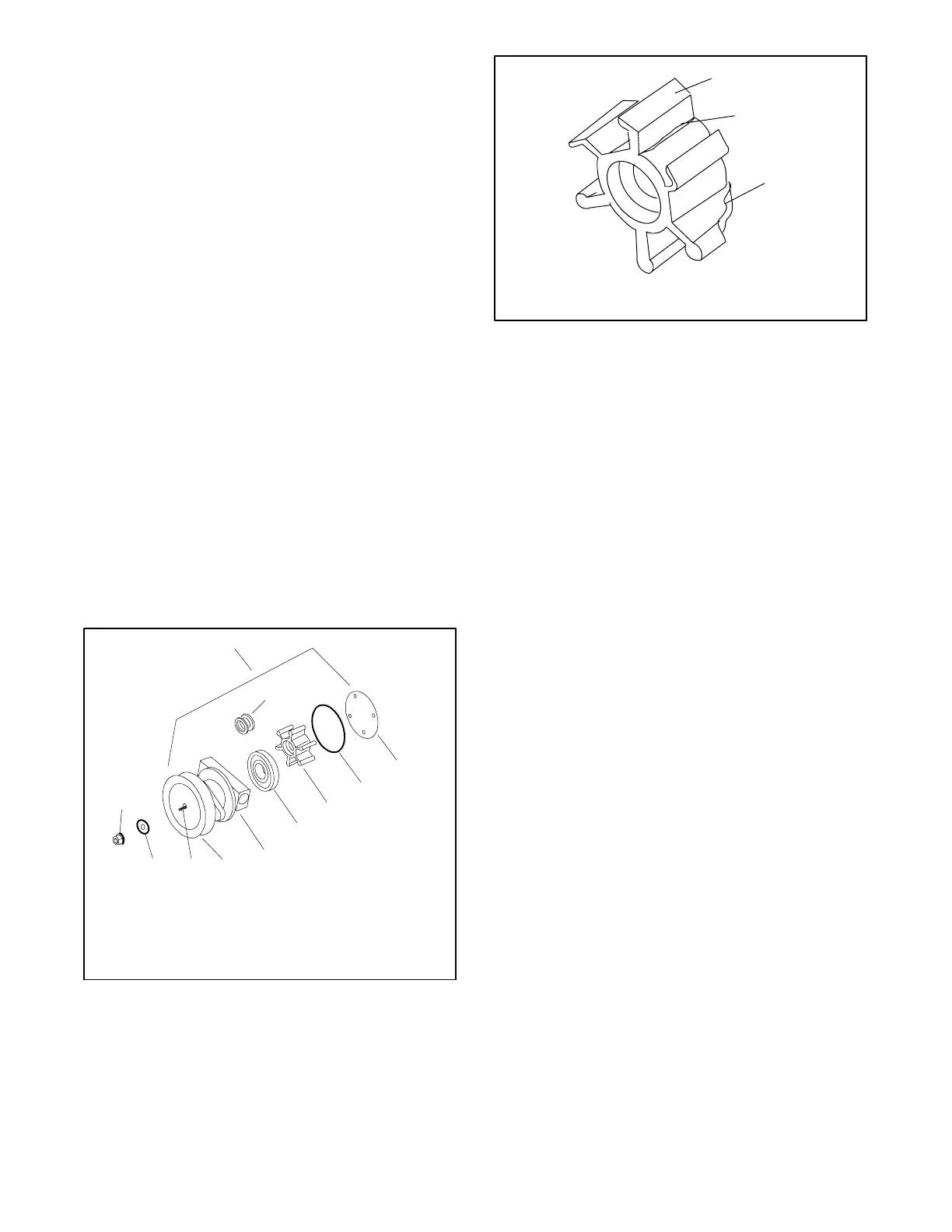

2. Remove the seawater pump coverplate. See

Figure 3-7.

3. Remove the impeller.

4. Inspect the impeller for damaged, cracked, broken,

missing or flattened vanes. The impeller vanes

should be straight and flexible. See Figure 3-8.

Replace the impeller if it is damaged.

1

2

3

4

5

6

78

9

10

1. Seawater pump

2. Coverplate

3. Gasket

4. Impeller

5. Bearing

6. Housing

7. Pulley

8. Drive shaft

9. Washer

10. Nut

11. Mechanical seal,

if equipped

TP-6053

11

Figure 3-7 Seawater Pump, Typical

1

2

3

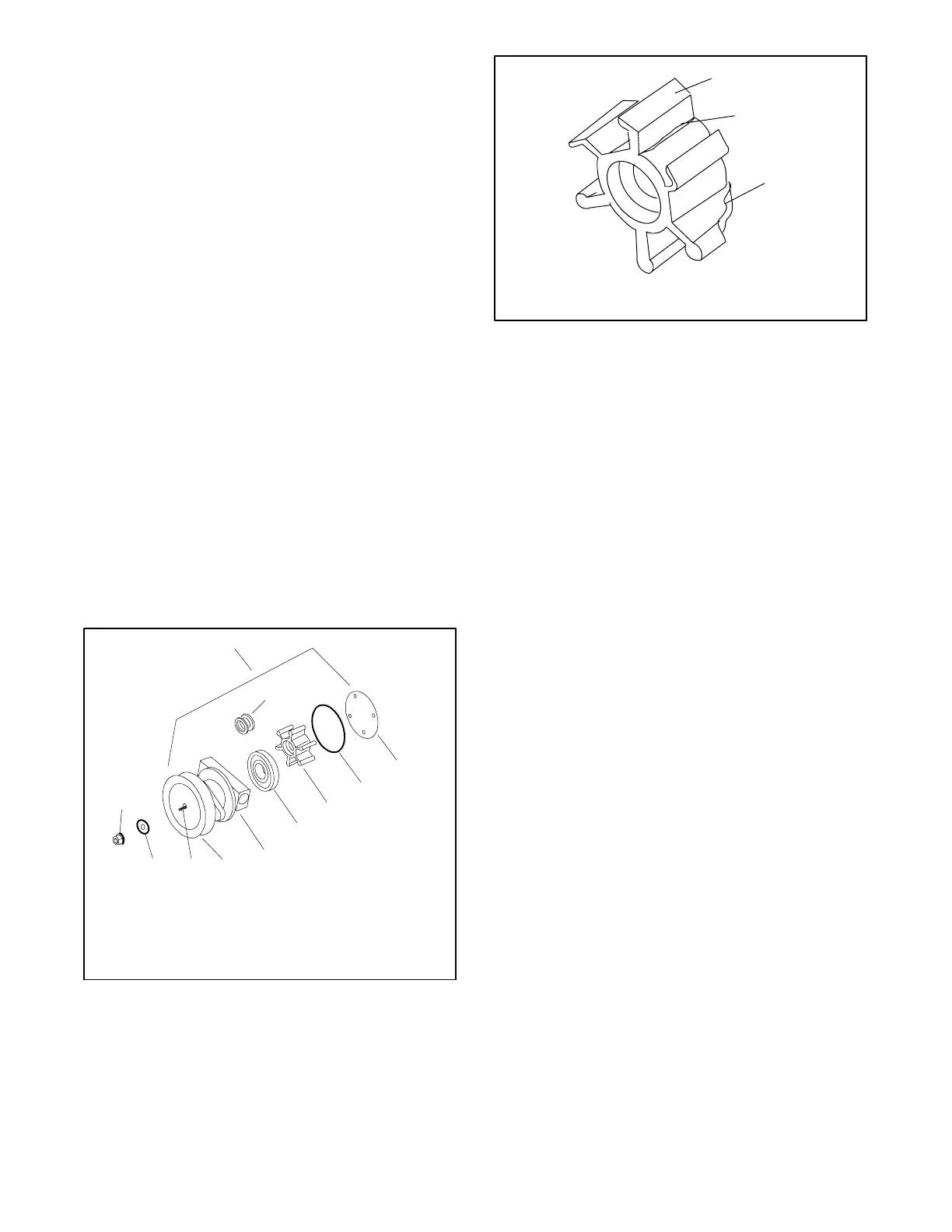

1. Flattened vane

2. Crack

3. Broken vane

TP-6053

Figure 3-8 Worn Impeller

5. Lubricate the impeller with soapy water before

installation.

6. Install the impeller.

Note: During installation push and rotate the

impeller in the same direction as the engine

rotation until it is thoroughly seated in the

impeller housing.

7. Inspect the coverplate and gasket for corrosion

and/or damage. Replace components as

necessary.

8. Lubricate the gasket with silicon grease and attach

the gasket and coverplate to the seawater pump

housing.

9. Open the seacock.

10. Start the generator set and check for leaks.

11. Stop the generator set and repair leaks or replace

damaged or worn components.

m:sm:003:008

Loading...

Loading...