TP-6196 10/0994 Section 6 Component Testing and Adjustment

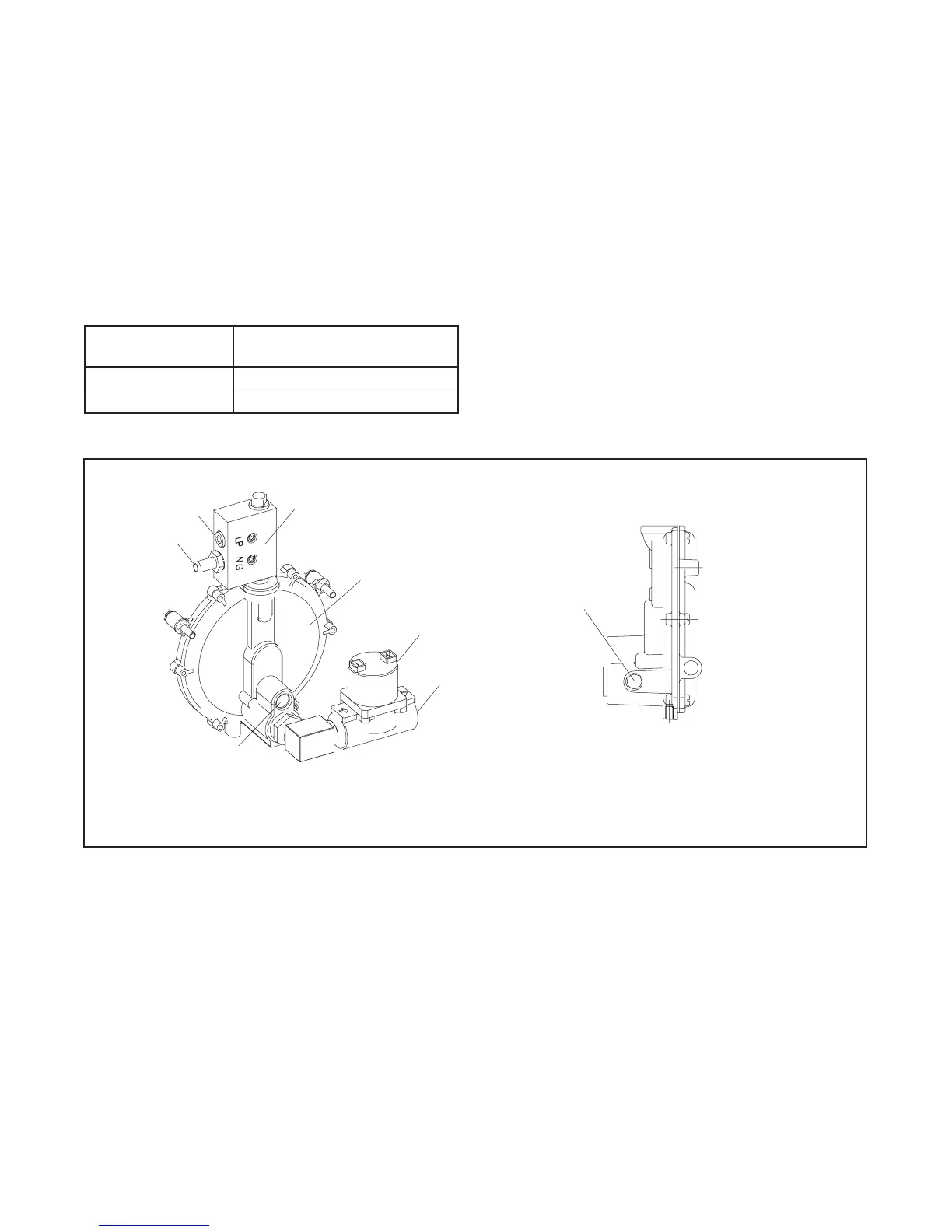

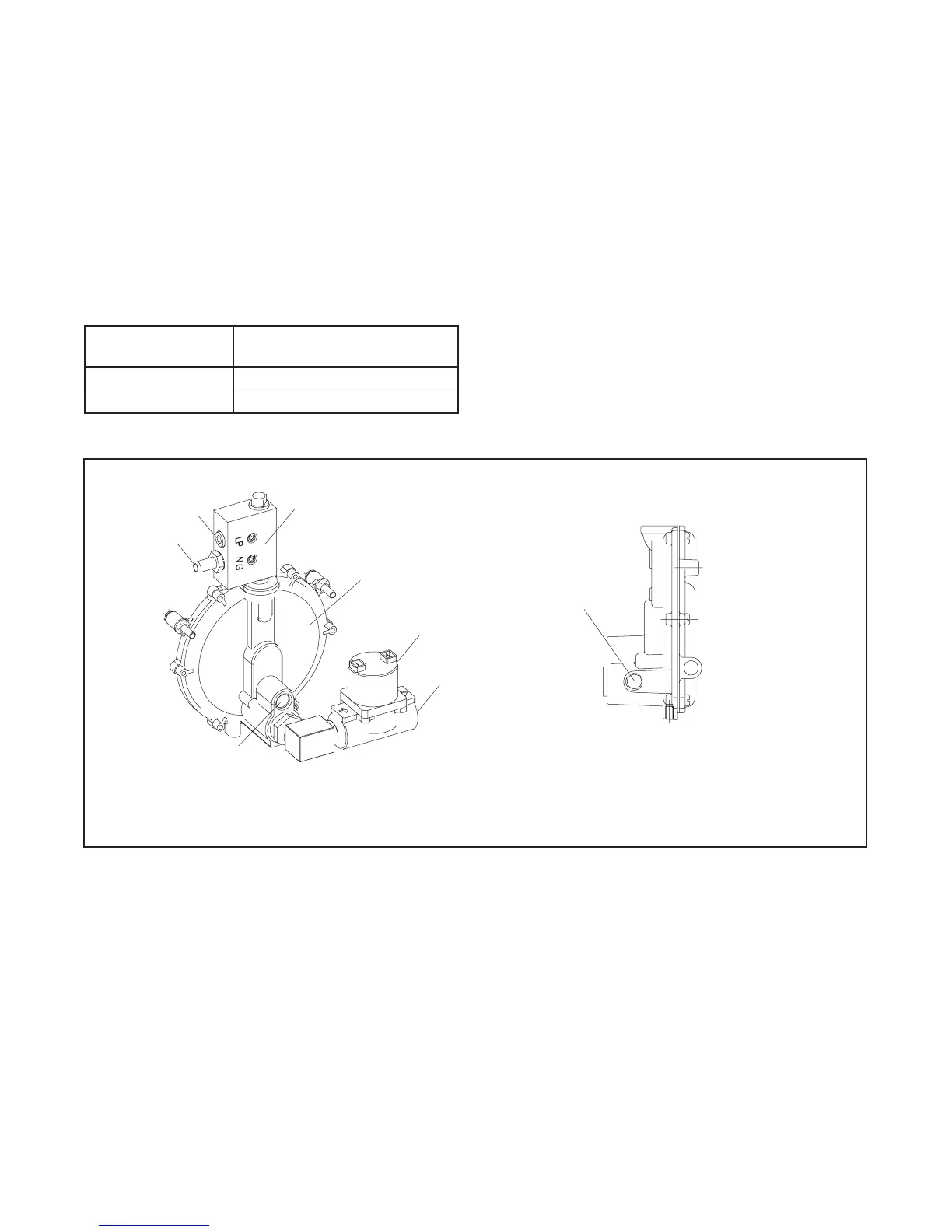

The fuel lock-off prevents fuel flow when the engine is

not operating. See Figure 6-35. Do not try to adjust the

fuel pressure, fuel mixture, or engine speed using the

fuel lock-off.

Checking the Fuel Pressure

Use a gauge or manometer to check the fuel pressure at

the secondary regulator inlet. See Figure 6-35.

Measure the fuel pressure with the generator set

running at rated load. Verify that the fuel pressure is

within the range shown in Figure 6-34. Contact the fuel

supplier if the inlet pressure is not within the specified

range.

Fuel Type

Supply Pr essure

kPa (in. water column)

Natural Gas 1.2--2.7 (5--11)

LP 1.7--2.7 (7--11)

Figure 6-34 Fuel Supply Pressure

6.12.4 Fuel Conversion

The multi-fuel system allows conversion from natural

gas to LP vapor (or vice-versa) in the field while

maintaining emissions-standard compliance. A trained

technician or authorized distributor/dealer can convert

the fuel system.

Two fuel connections on the fuel metering valve allow

field conversion between natural gas and LP vapor. The

fuel metering valves are factory-set and sealed to

comply with applicable emission standards and to

provide the best possible hot and cold starting.

TP-6196

2

1. Hose fitting

2. Plug

3. Fuel metering valve (factory-sealed, do not adjust)

4. Secondary regulator

5. Fuel solenoid valve

6. Fuel inlet, 1/2 in. NPT

7. Fuel lockoff (do not adjust)

8. Inlet pressure check location

3

1

7

6

8

4

5

Regulator, Side View

Figure 6-35 Fuel Regulator, Fuel Metering Valve, and Fuel Solenoid Valve

Loading...

Loading...